Torsion-prevention shock-insulation tensile structure for construction projects

A technology for construction engineering and building structure, which is applied to building components, earthquake resistance, etc., can solve the problem of insufficient tensile capacity of laminated rubber isolation bearings, affecting the horizontal shock absorption coefficient of vibration isolation bearings, and inability to fully limit vibration isolation bearings. Tensile displacement and other problems, to achieve the practical value of large projects, solve the problem of tensile strength, and facilitate maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

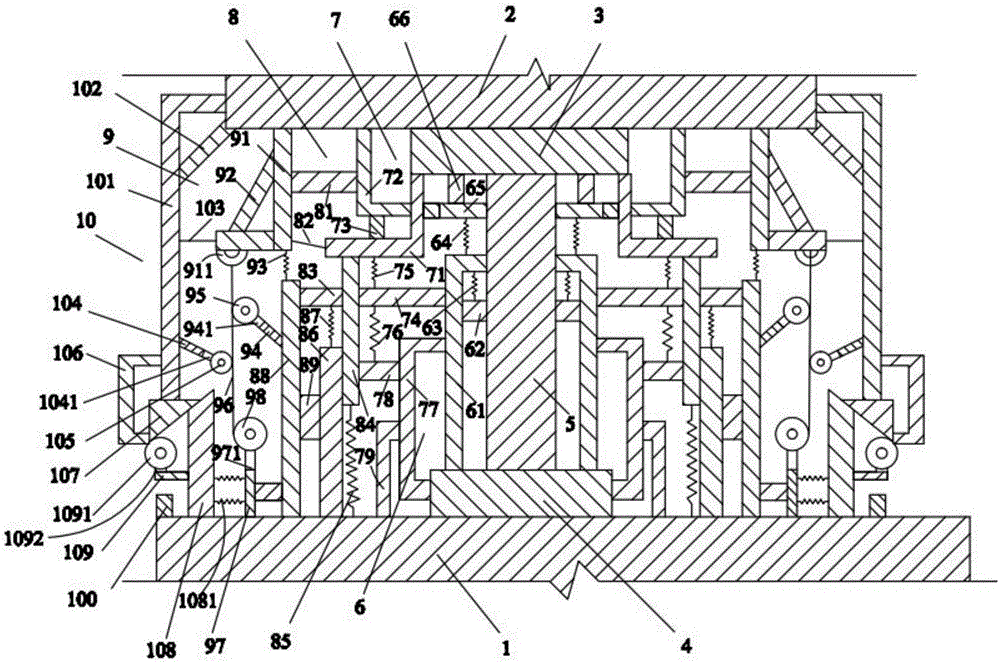

[0019] In the following, a clear and complete description will be made of the anti-torsion, seismic isolation and tensile structure for construction engineering of the present invention in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, the anti-torsion, seismic isolation and tensile structure for construction engineering of the present invention is arranged between the lower building structure 1 and the upper building structure 2, which includes an upper buttress 3, a lower buttress 4 located below the upper buttress 3, The shock-isolation support 5 between the upper buttress 3 and the lower buttress 4, the first shock-isolation device 6 on one side of the shock-isolation support 5, the first shock-isolation device 6 on one side The second shock-isolating device 7, the third shock-isolating device 8 on one side of the second shock-isolating device 7, the fourth shock-isolating device 9 on one side of the third shock-isolating device 8, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap