Pad printing machine with servo shuttling glue heads descending independently

A technology of pad printing machine and glue head, which is applied in printing machine, rotary printing machine, printing, etc., can solve the problems that pad printing machine cannot meet the application requirements, affect the printing effect, and is easy to dry, so as to facilitate the digitization and standardization of operations , low noise, saving ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

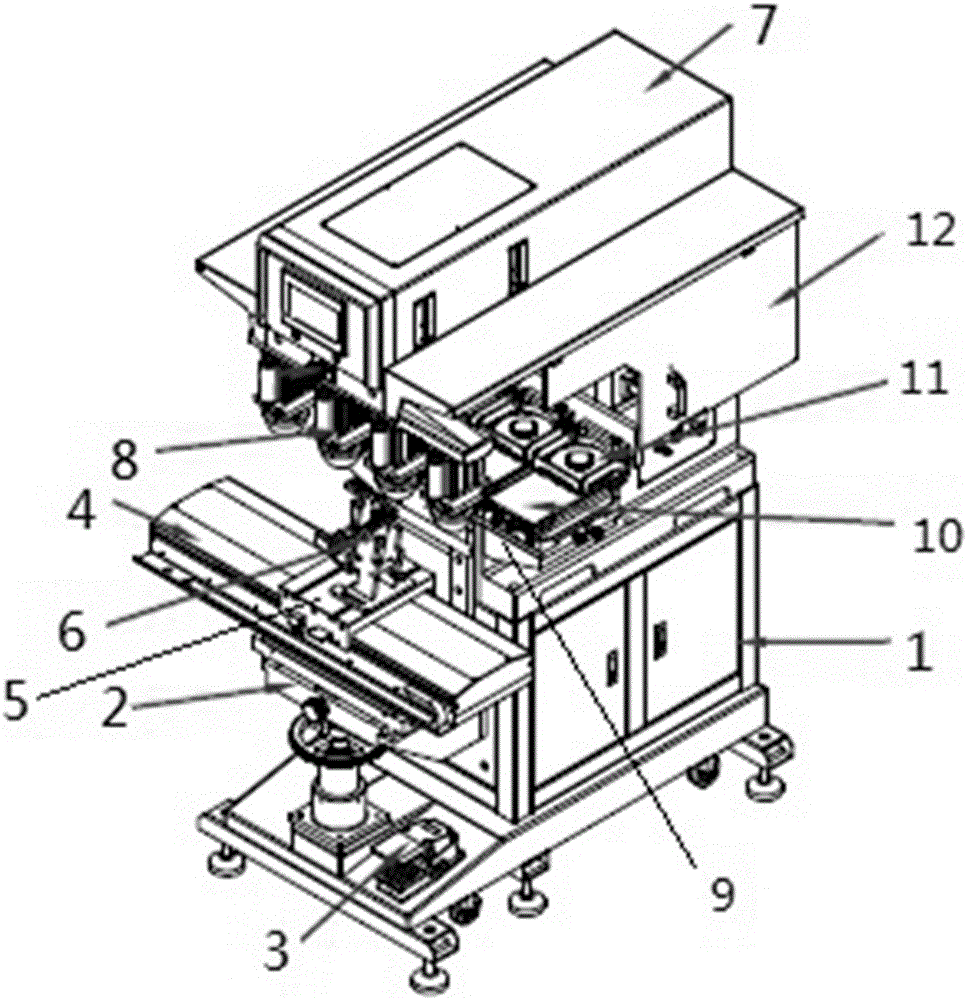

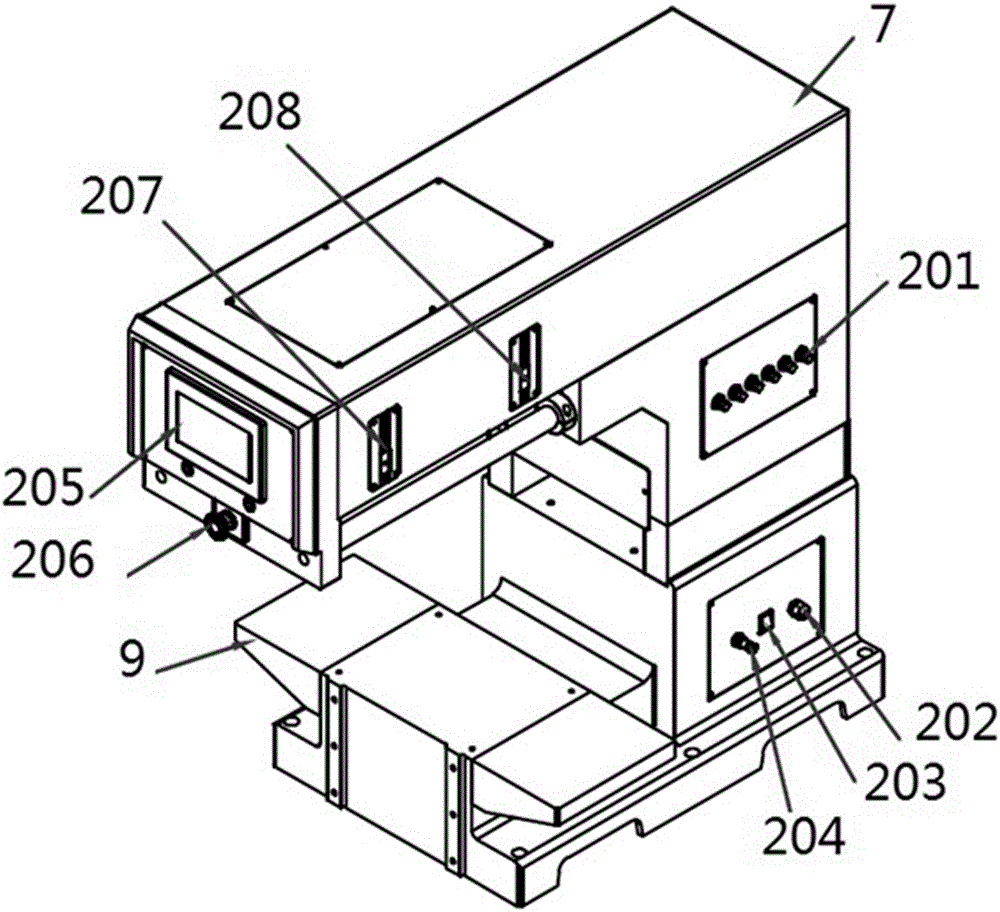

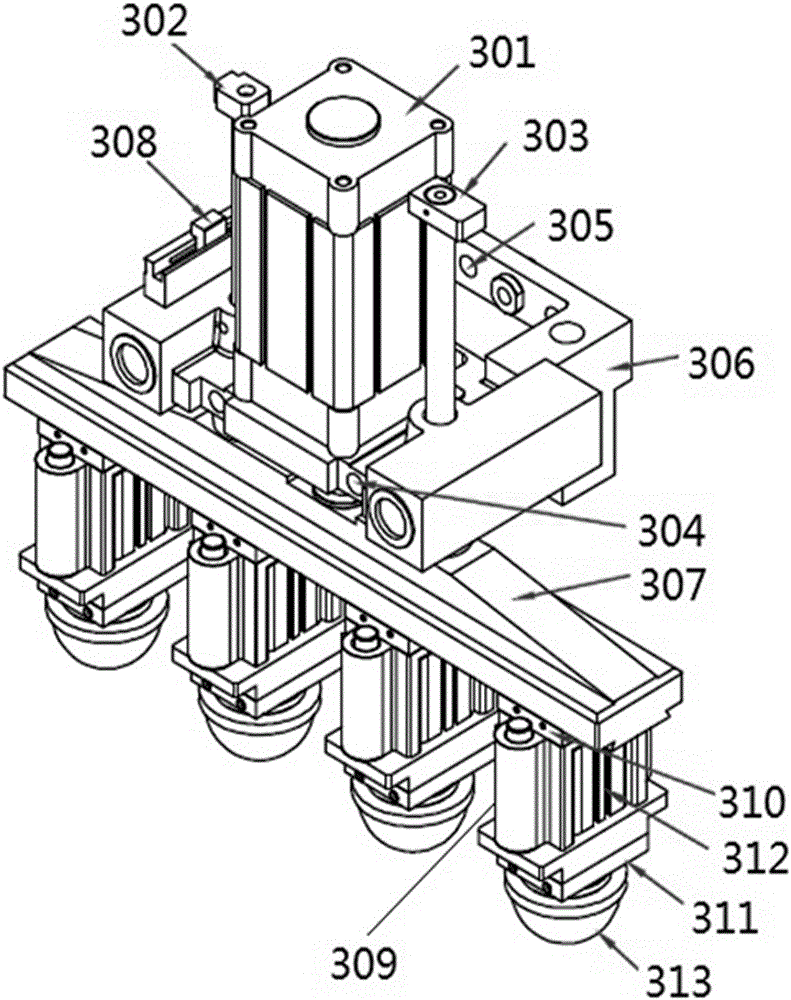

[0038] A kind of servo shuttle rubber head independent descending pad printing machine of this embodiment, such as Figure 1-Figure 11 As shown, including a frame 1, the frame 1 is provided with an elevating table 2 and a foot switch 3, and an electronic servo pusher 4 is fixedly arranged on the elevating table 2, and the electronic servo pusher 4 includes a shuttle table that can slide left and right Plate 5 is fixedly connected with a fixture 6 for clamping or limiting and fixing the product to be printed on the shuttle table 5; a pad printing machine base 7 is also provided on the frame 1, and a printing machine base 7 is provided on the pad printing machine base 7. The seat 8 and the reinforcing rib 9 are provided with a steel plate component 10 on the reinforcing rib 9, and an independent pushing component 11 of the oil cup is provided on the steel plate component 10. The exterior of the pad printing machine base 7 is covered with a safety baffle 12 .

[0039] The base 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com