Light guide plate machining device of optimized structure

A processing device and optimized structure technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of low product yield, low efficiency, and difficulty in finding defective products in time, so as to improve input efficiency, The effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

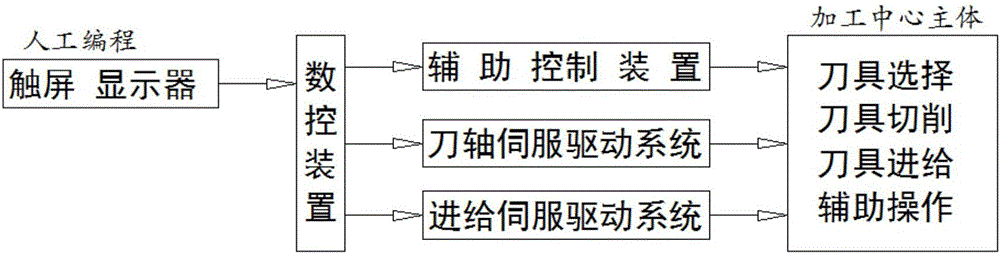

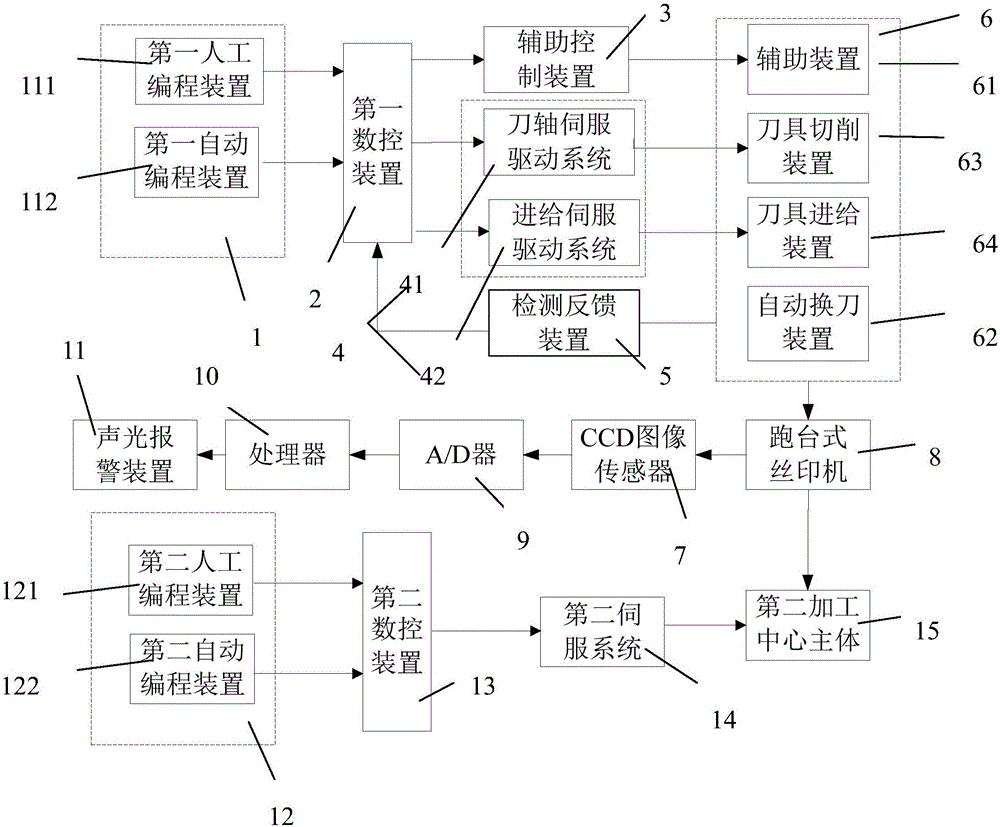

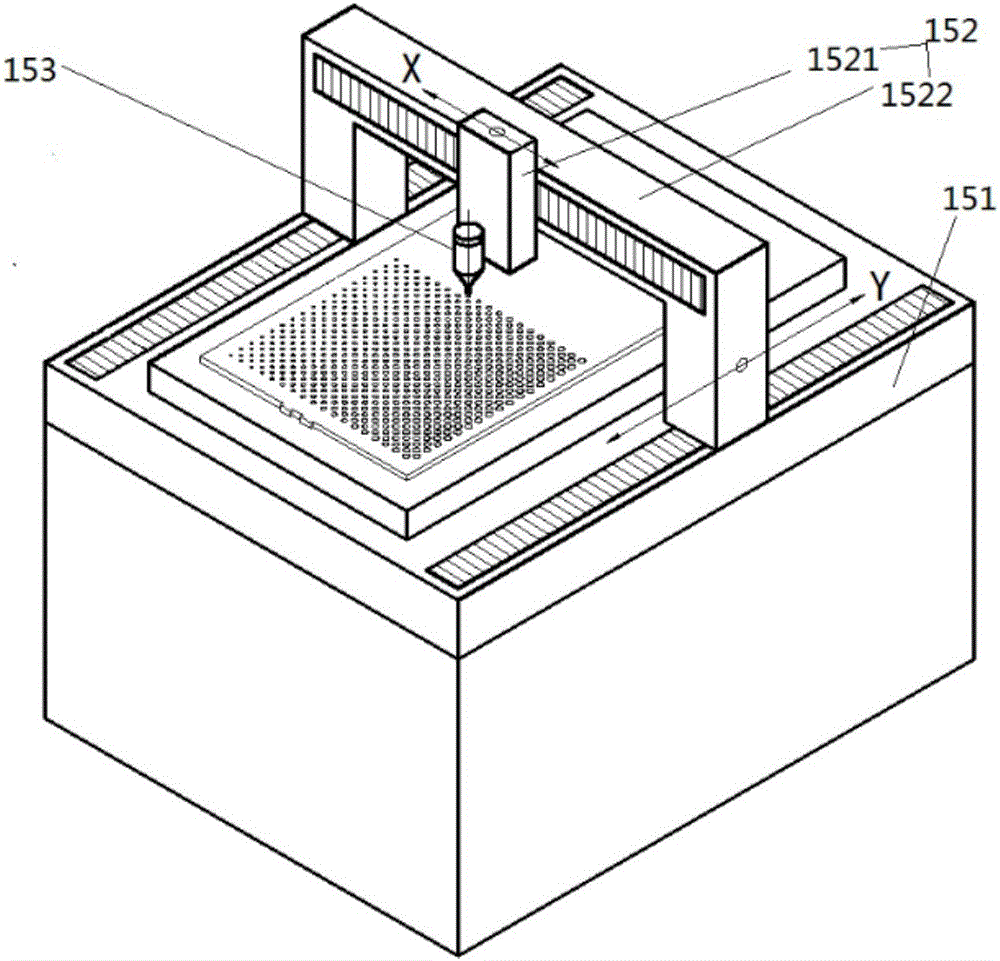

[0020] Such as Figure 2-4 As shown, the embodiment of the present invention includes a light guide plate side processing center, a light guide plate screen printing dot processing main device, and a light guide plate dot replenishment device. The light guide plate side processing center mills and polishes the side of the light guide plate to be processed, and the light guide plate screen printing dot processing main device performs dot processing on the milled and polished light guide plate. The dot replenishing device for dots on the light guide plate performs dot replenishment processing for missing ink dots on the light guide plate. The light guide plate side processing center includes a first input device 1 , a first numerical control device 2 , an auxiliary control device 3 , a first servo system 4 , a detection feedback device 5 and a first processing center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com