Classified thermal desorption repair system and technology of organic contaminated soil

A technology of organic pollution and remediation system, applied in the field of contaminated soil remediation, can solve the problems of low heat energy utilization efficiency, high operating cost, high energy consumption of treatment, etc., achieve efficient remediation, low operating cost, and avoid over-treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

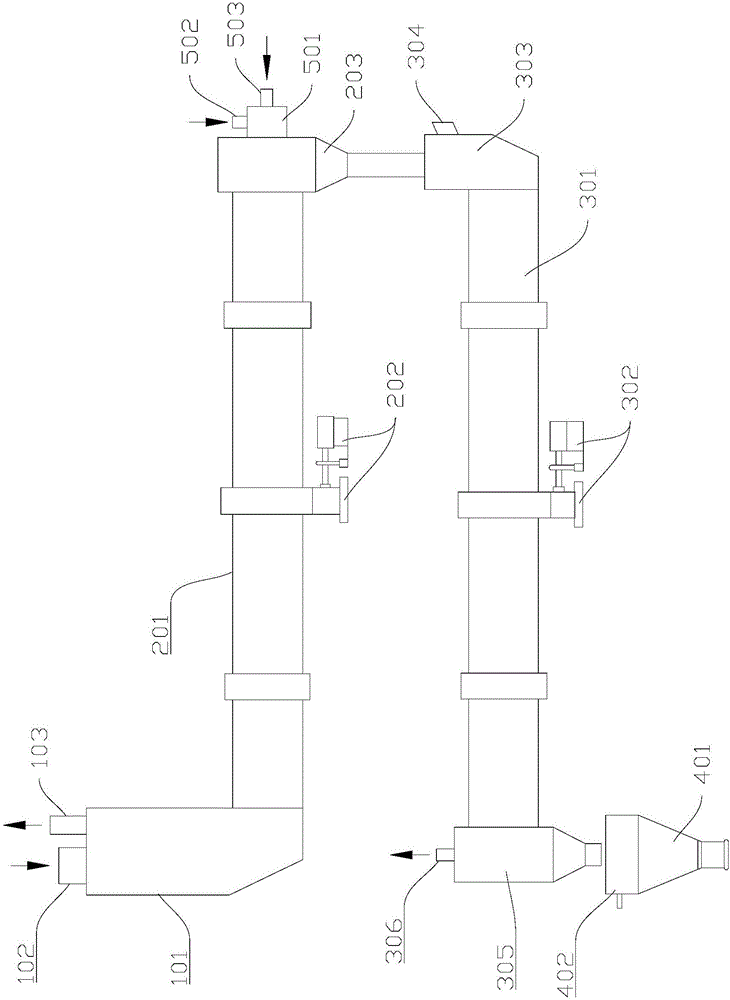

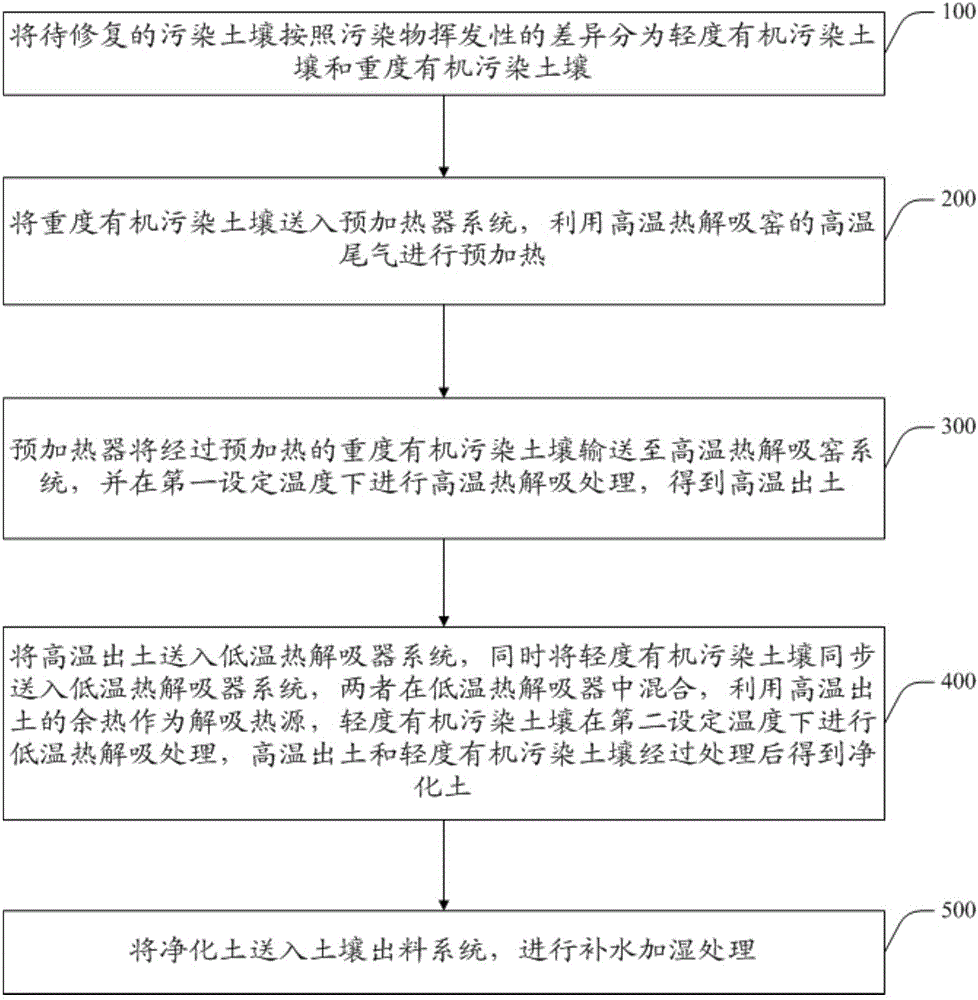

[0038] see figure 1 As shown, the embodiment of the present invention provides a thermal desorption remediation system for organic polluted soil, including a preheater system, a high temperature thermal desorption kiln system, a low temperature thermal desorber system and a soil discharge system; a preheater system, The high-temperature thermal desorption kiln system, the low-temperature thermal desorber system and the soil discharge system are connected in sequence. In this embodiment, a pre-heater system is set up to make full use of the high-temperature tail gas produced by the high-temperature pyrolysis kiln system, which improves the utilization rate of heat energy; the high-temperature thermal desorption kiln system and the low-temperature thermal desorber system are used to treat organically polluted soils with different pollution degrees respectively. , which greatly reduces the energy consumption of thermal desorption treatment, and the operating cost is low.

[0039...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com