A kind of sodium alginate-based pH-responsive drug microcapsules and preparation method thereof

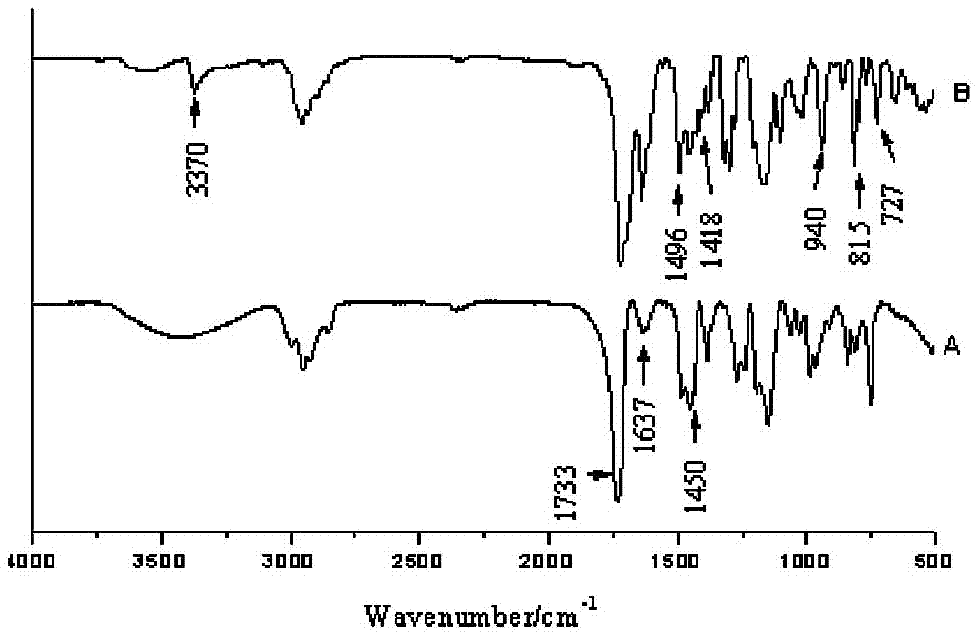

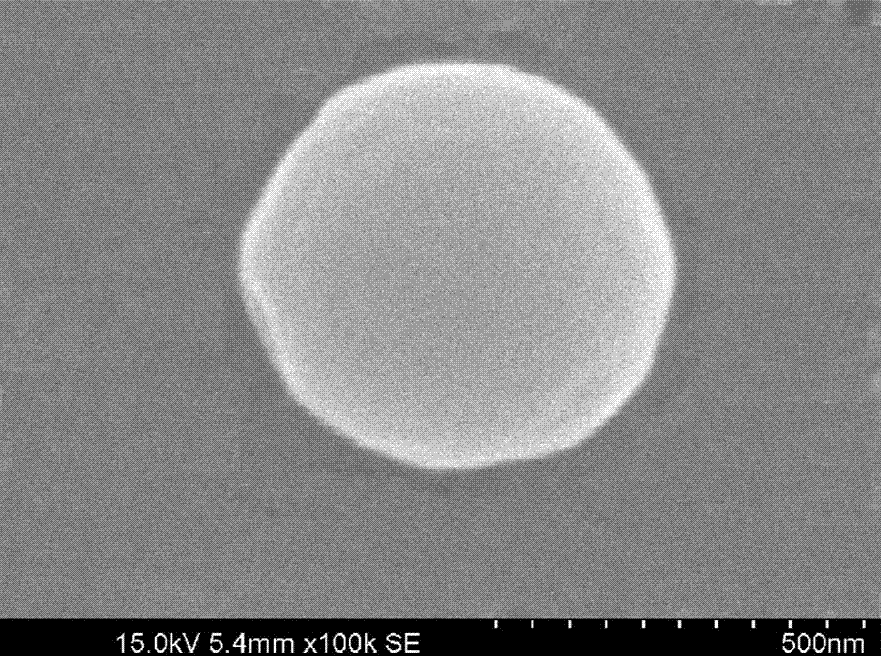

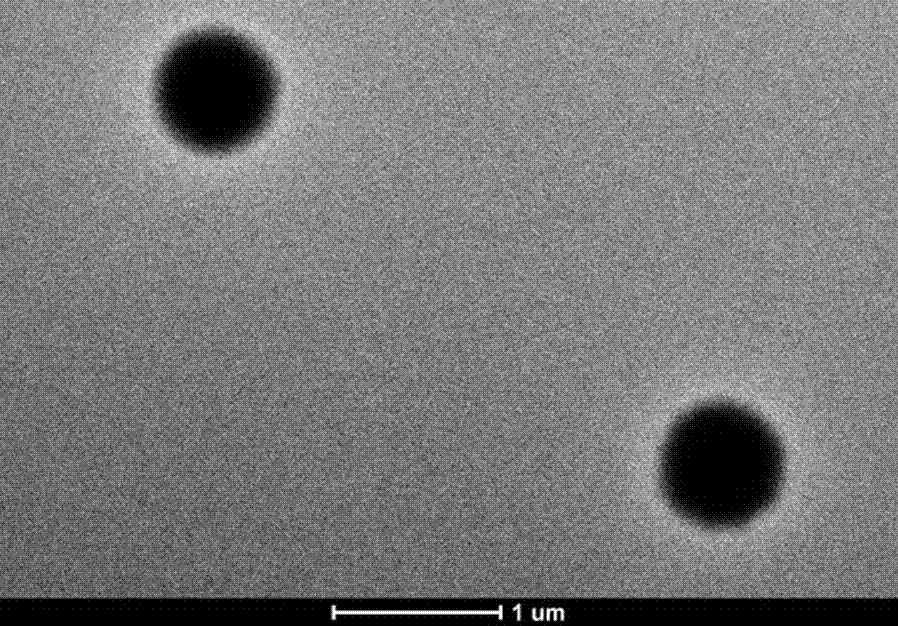

A technology of sodium alginate and microcapsules, which is applied in microcapsules, capsule delivery, pharmaceutical formulations, etc. It can solve the problems of unstable drug release performance, poor mechanical properties of wall materials, and large particle size of microcapsules, so as to improve hydrophilicity non-toxic, smooth surface and evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Take 25mL of ethyl acetate, add 10g of methyl methacrylate, 0.8g of cross-linking agent 1,4-butanediol dimethacrylate and 1.5g of felodipine in turn to the ethyl acetate, stir well, get oily phase;

[0045] (2) Take 300mL of water, add 4g of sodium alginate and 0.08g of surfactant poloxamer-188 into the water, stir well to obtain the water phase;

[0046] (3) Add the oil phase to the water phase, and use a high-speed shear emulsifier to shear and emulsify for 9 minutes at a shear rate of 8000 r / min to obtain an oil / water emulsion;

[0047] (4) Put the prepared oil / water emulsion into the mixture equipped with agitator, constant pressure dropping funnel, N 2 four-necked flask with catheter and thermometer, in N 2 Stir mechanically under the atmosphere, heat to 60°C, slowly add 150mL aqueous solution containing cerium ammonium nitrate with a concentration of 0.0027g / mL (a solution obtained by dissolving 0.4g of cerium ammonium nitrate in 150mL of water); keep the te...

Embodiment 2

[0049] (1) Take 23mL of ethyl acetate, add 8g of ethyl methacrylate, 0.6g of cross-linking agent 1,4-butanediol dimethacrylate and 1.0g of felodipine in turn to the ethyl acetate, stir well, get oily phase;

[0050] (2) Take 225 mL of water, add 3 g of sodium alginate and 0.06 g of surfactant poloxamer-188 into the water, stir well to obtain the water phase;

[0051] (3) Add the oil phase to the water phase, and use a high-speed shear emulsifier to emulsify for 9 minutes at a shear rate of 8000r / min to obtain an oil / water emulsion;

[0052] (4) Put the prepared oil / water emulsion into the mixture equipped with agitator, constant pressure dropping funnel, N 2 four-necked flask with catheter and thermometer, in N 2 Stir mechanically under the atmosphere, heat to 60°C, slowly add 113mL aqueous solution containing cerium ammonium nitrate with a concentration of 0.0027g / mL (a solution obtained by dissolving 0.3g of cerium ammonium nitrate in 113mL of water); keep the temperature ...

Embodiment 3

[0054] (1) Take 30 mL of ethyl acetate, add 12 g of butyl methacrylate, 1.0 g of cross-linking agent 1,4-butanediol dimethacrylate and 2.0 g of felodipine in sequence, and stir well , to get the oil phase;

[0055] (2) Take 375mL of water, add 5g of sodium alginate and 0.1g of surfactant poloxamer-188 into the water, stir well to obtain the water phase;

[0056] (3) Add the oil phase to the water phase, and use a high-speed shear emulsifier to shear and emulsify for 9 minutes at a shear rate of 8000 r / min to obtain an oil / water emulsion;

[0057] (4) Put the prepared oil / water emulsion into the mixture equipped with agitator, constant pressure dropping funnel, N 2 four-necked flask with catheter and thermometer, in N 2 Stir mechanically under the atmosphere, heat to 60°C, slowly add dropwise 188mL aqueous solution containing 0.0027g / mL cerium ammonium nitrate (a solution obtained by dissolving 0.5g cerium ammonium nitrate in 188mL water); keep the temperature constant, react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com