Abelmoschus esculentus soft can and preparation method of the abelmoschus esculentus soft can

A production method and a technology for soft canned food are applied in the directions of food preparation, food ingredients as taste improvers, food preservation, etc., which can solve the problems of difficulty in long-term low-temperature storage, brown spots, and waste of resources, so as to ensure edible quality and food safety. , Keep bright green and crispness, the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1. Optimization of blanching conditions

[0060] (1) Raw material selection and cleaning: Choose fresh okra tender clips with no mechanical damage, no pests, no mildew, no brown spots, moderate maturity, dark green color, and full fruit pods. Use running water to wash away the entrained dust, impurities, etc., and drain the water for later use.

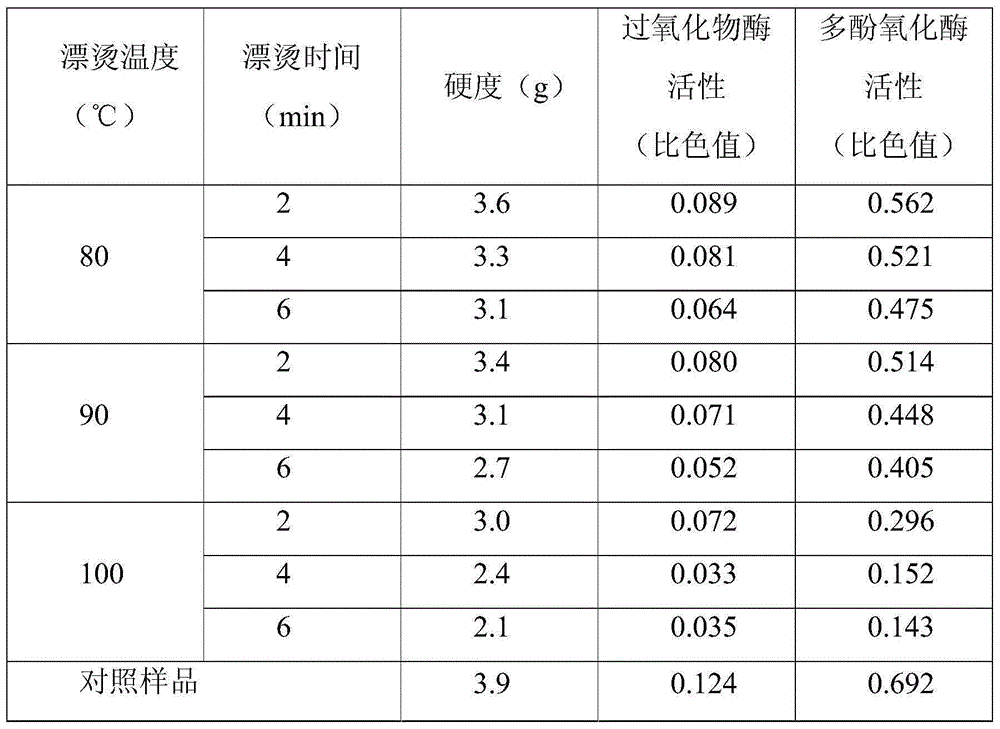

[0061] (2) Blanching and cooling: blanch the cleaned okra tenderly in hot water at different temperatures for different times, and immediately place it in cold water for cooling. The hardness, peroxidase activity, and polyphenol oxidase activity of the tender clip were used as indicators to optimize the temperature and time of the blanching conditions. The untreated tender clip was used as a control. The experimental results are shown in Table 1.

[0062] Table 1. The effect of blanching temperature and time on the hardness and enzyme activity of okra

[0063]

[0064] It can be seen from Table 1 that under the same blanching ...

Embodiment 2

[0065] Example 2. Optimization of Green Protection Conditions

[0066] (1) Raw material selection and cleaning: Choose fresh okra tender clips with no mechanical damage, no pests, no mildew, no brown spots, moderate maturity, dark green color, and full fruit pods. Use running water to wash away the entrained dust, impurities, etc., and drain the water for later use.

[0067] (2) Blanching and cooling: blanch the cleaned okra tenderly in hot water at 100°C for 4 minutes, and immediately place it in cold water to cool. As the effect of blanching at 100°C for 4 minutes is the best in Example 1, this temperature and time are selected.

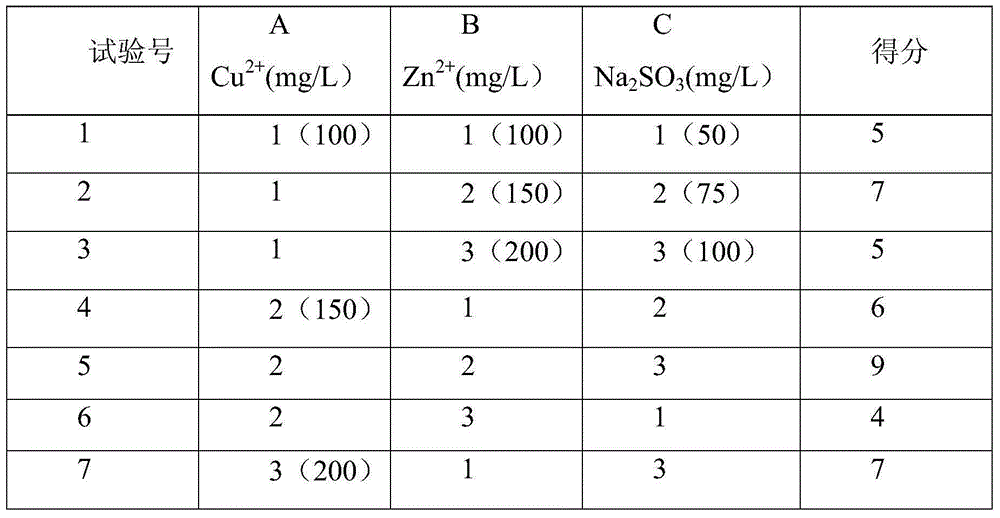

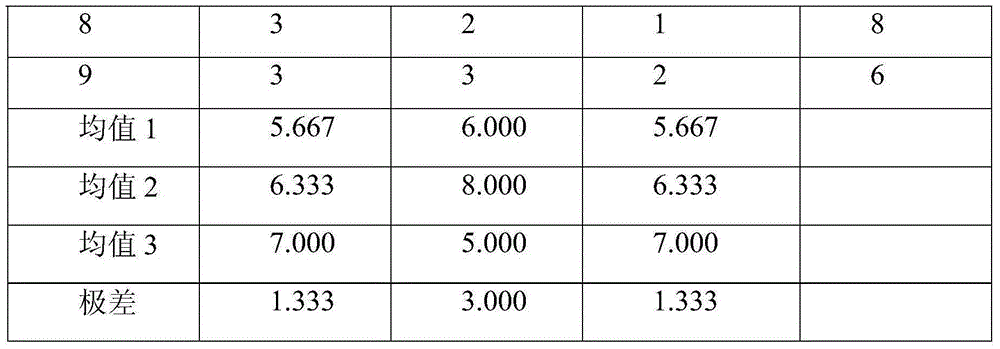

[0068] (3) Green protection and rinsing: the blanched okra tender clips are soaked in different green protection solutions for different periods of time. After the treatment, the tender clips are fully washed. The following uses the color of the okra tender clip as the scoring standard to optimize the soaking time in the green protection process and the...

Embodiment 3

[0078] Example 3: Optimization of hardening and brittleness preservation conditions

[0079] (1) Raw material selection and cleaning: Choose fresh okra tender clips with no mechanical damage, no pests, no mildew, no brown spots, moderate maturity, dark green color, and full fruit pods. Use running water to wash away the entrained dust, impurities, etc., and drain the water for later use.

[0080] (2) Blanching and cooling: blanch the cleaned okra tenderly in hot water at 100°C for 4 minutes, and immediately place it in cold water to cool.

[0081] (3) Green protection and rinsing: soak the blanched okra tender clips in the green protection solution (150mg / L Cu 2+ Concentration, 150mg / L Zn 2+ And 100mg / L of Na 2 SO 3 ) Soak for 60min to protect the green. After the treatment, the tender clips are fully cleaned. Since this condition is the best in Example 2, this time and formula are selected.

[0082] (4) Hardening and rinsing: Under vacuum conditions (vacuum degree is 0.05MPa), the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com