multi-axis drive

A technology of a driving device and a switching device, which is applied to the deceleration device of a DC motor, a conversion device of output power, and the control of an AC motor, etc., can solve the problems of high cost, complexity, and inability to realize the miniaturization of the device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

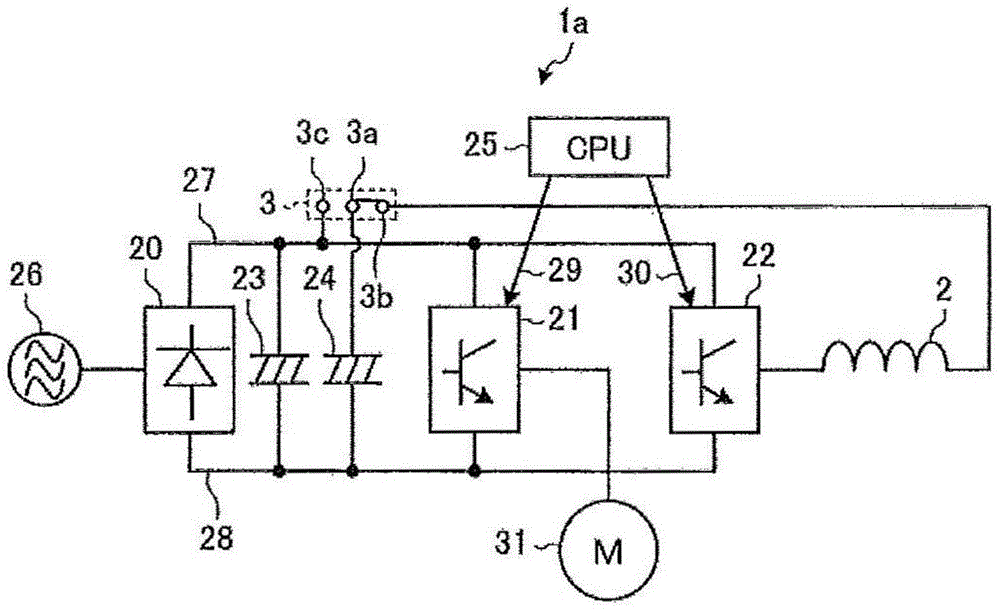

[0035] figure 1 It is a block diagram showing the configuration of the multi-axis drive device according to Embodiment 1 of the present invention. In the first embodiment and the five embodiments described later, an application example to a multi-axis drive device having a structure capable of driving two motors is shown for easy understanding.

[0036] First, for ease of understanding, refer to figure 1 , a multi-axis driving device having a structure capable of driving two motors will be briefly described. That is, in figure 1 Among them, a multi-axis driving device having a structure capable of driving two motors generally includes: a converter circuit 20 ; inverter circuits 21 and 22 ; bus voltage smoothing capacitors 23 and 24 ; and a control unit 25 .

[0037] The converter circuit 20 is a full-wave rectification circuit composed of a diode bridge, and converts a commercial AC power supply 26 into a DC power supply. The inverter circuits 21 and 22 are arranged in par...

Embodiment approach 2

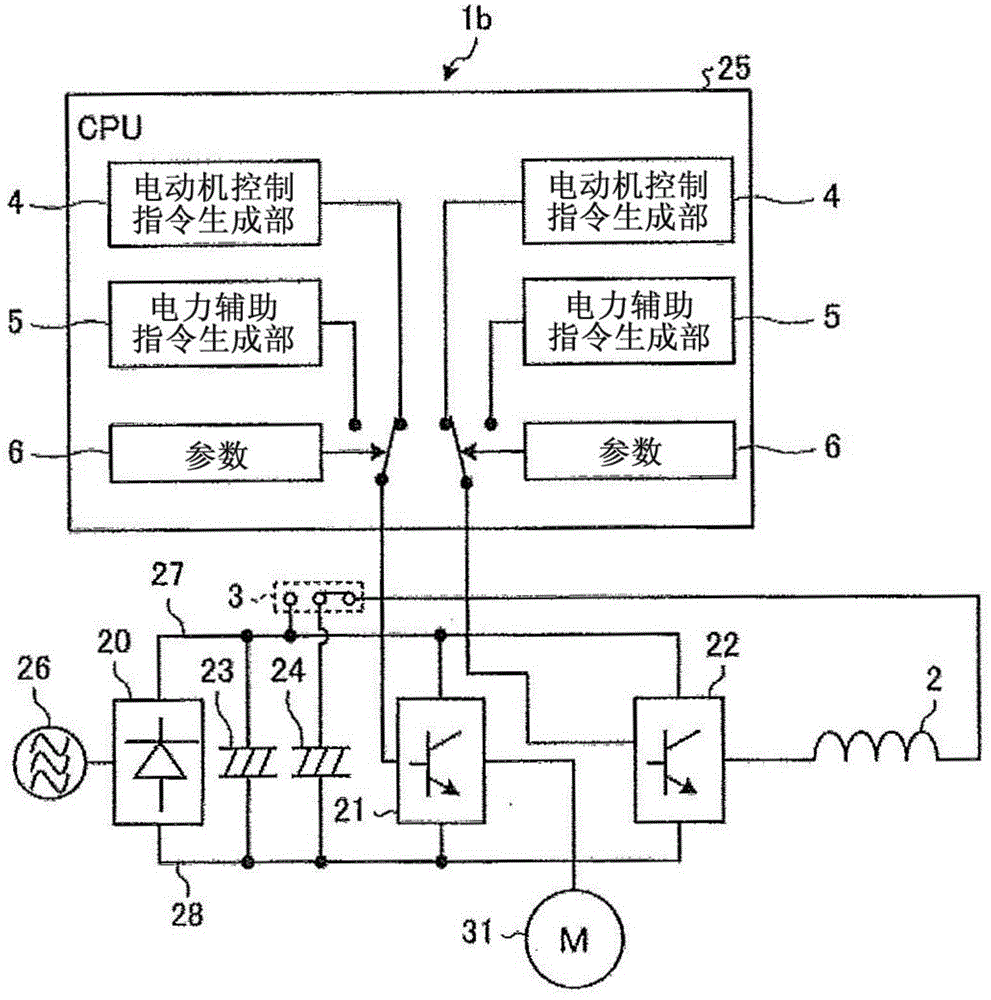

[0049] figure 2 It is a block diagram showing the configuration of the multi-axis drive device according to Embodiment 2 of the present invention. In addition, in figure 2 in, right with figure 1 The same or equivalent structural elements shown in (Embodiment 1) are denoted by the same reference numerals. Here, the description will focus on the part related to the second embodiment.

[0050] exist figure 2 In the multi-axis driving device 1b according to the second embodiment, in figure 1 The specific configuration content of the control unit 25 is shown in addition to the configuration shown in (Embodiment 1). Other structures of the multi-axis driving device 1b and figure 1 The structure of the multi-axis drive device 1a is the same.

[0051] That is, the control unit 25 is provided with a motor control command generation unit 4 , an electric power assist command generation unit 5 , and a parameter 6 for each inverter circuit. exist figure 2 In , since there are...

Embodiment approach 3

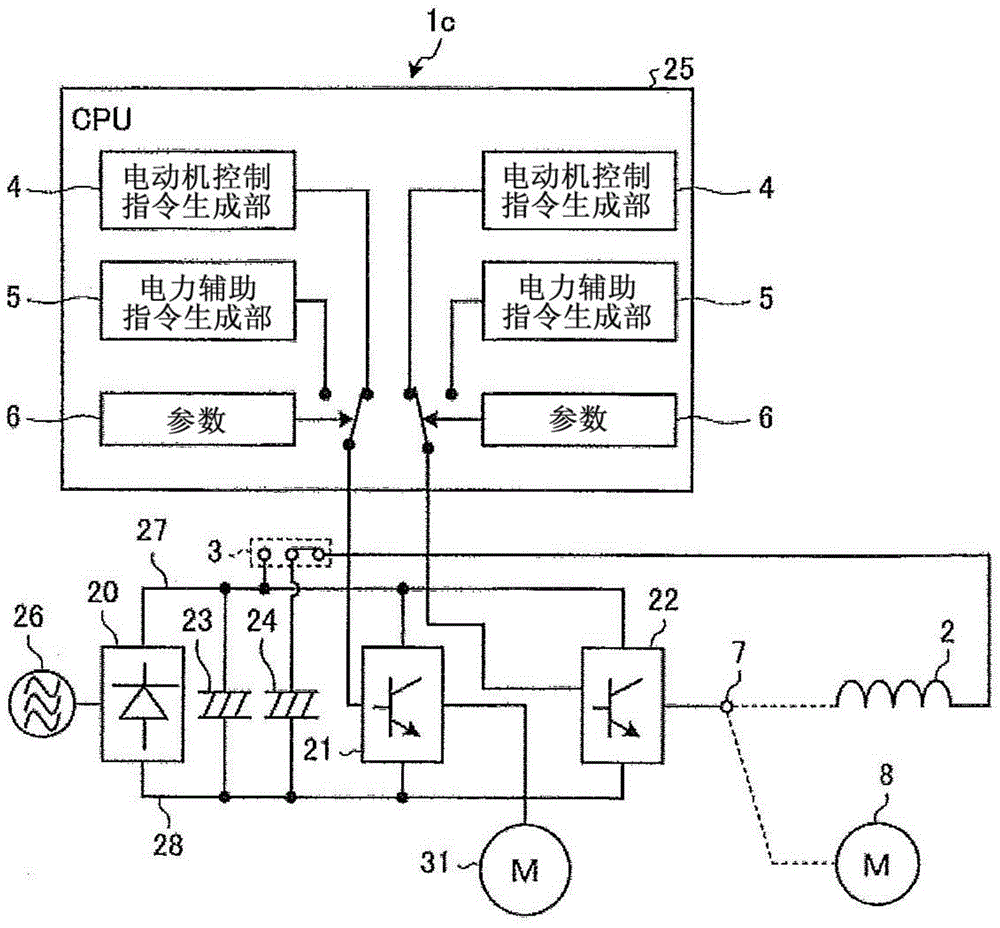

[0057] image 3 It is a block diagram showing the configuration of the multi-axis drive device according to Embodiment 3 of the present invention. In addition, in image 3 in, right with figure 2 The same or equivalent structural elements shown in (Embodiment 2) are denoted by the same reference numerals. Here, the description will focus on the parts related to Embodiment 3. FIG.

[0058] exist image 3 Among them, in the multi-axis drive device 1c according to the third embodiment, in figure 2 In the configuration shown in (Embodiment 2), the output terminal of the inverter circuit 22 is switchably connected to one end of the reactor 2 and the motor 8 via the switching device 7 that does not depend on electric signals.

[0059] The switching device 7 that does not depend on electric signals is a terminal block or a connector, and has a structure that one end of the reactor 2 and the motor 8 are switched and connected to the switching device 7 by manual work, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com