Installation and adjustment system and method for multi-layer nested X-ray grazing incidence optical lens

An optical lens and X-ray technology, applied in the field of space optics, can solve the problems of unsuitable optical lens, large installation and adjustment force, etc., and achieve the effect of high installation and adjustment efficiency, reduced deformation, and easy realization

Active Publication Date: 2015-11-18

BEIJING INST OF CONTROL ENG

View PDF5 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0052] The system and method for installing and adjusting the multi-layer nested X-ray grazing incidence optical lens of the present invention can adjust the maximum outer diameter of the lens to 500 mm, the minimum outer diameter is 40 mm, the adjustment accuracy is better than 0.1 μm, and the estimated adjustment speed is 15 minutes / 1 layer lens.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

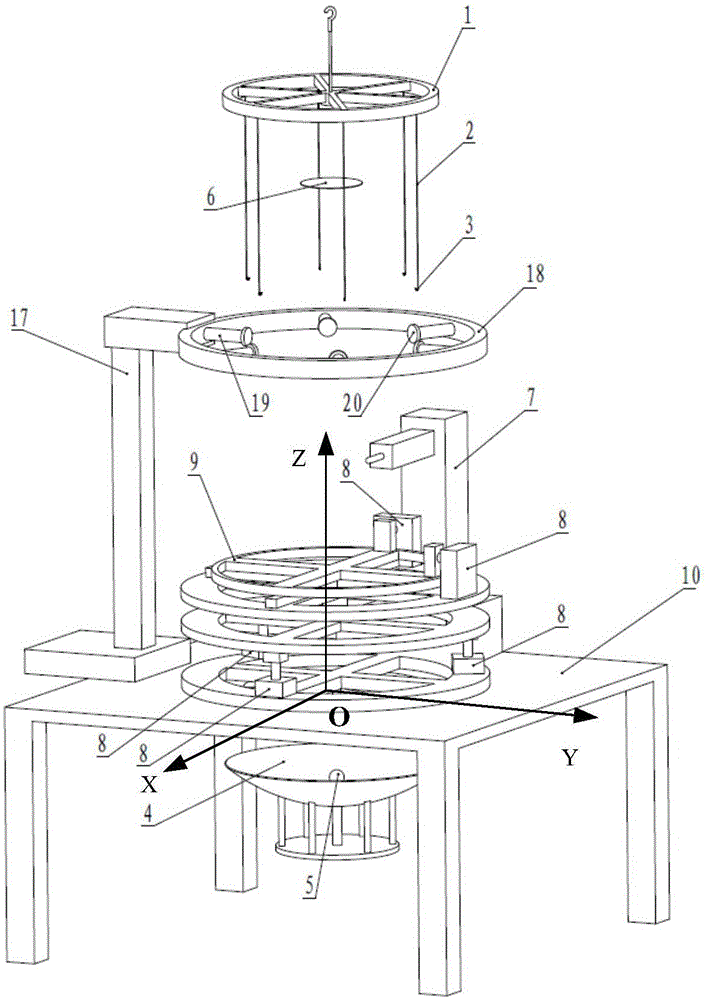

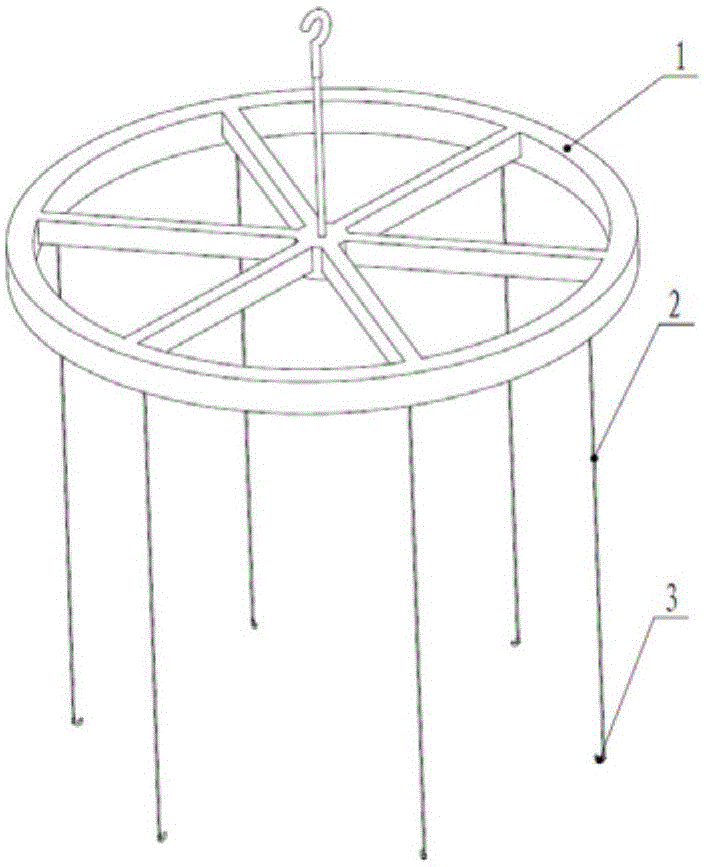

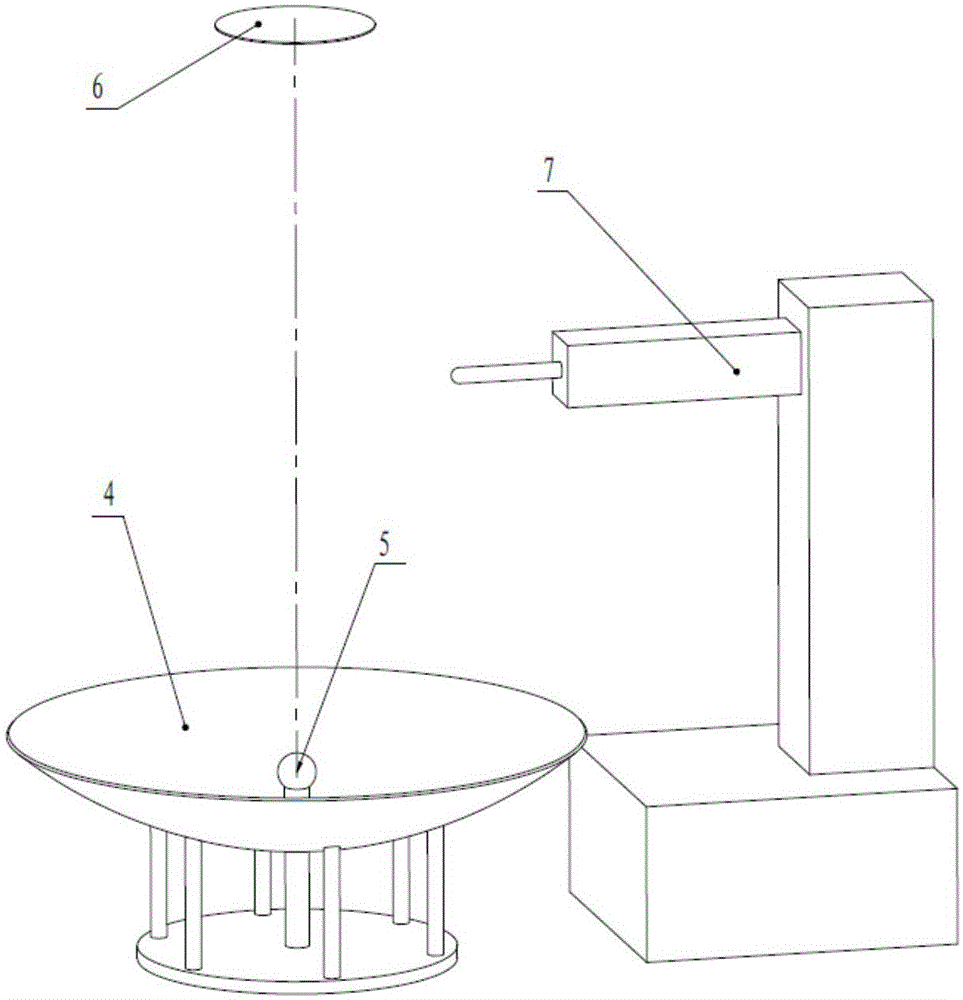

The invention proposes an installation and adjustment system and method for a multi-layer nested X-ray grazing incidence optical lens, and the system comprises a suspension subsystem, a measurement subsystem, a displacement subsystem, a pre-installation supporting device, an optical supporting platform, and a focal plane receiving screen. The method comprises seven steps: preparation, suspension, pre-installation, alignment, measurement, binding, and supporting structure installation. The system and method can greatly improve the installation and adjustment precision, speed and yield of the multi-layer nested X-ray grazing incidence optical lens, achieve no-stress installation and adjustment, improve the optical performance, are easy to implement, is high in universality, is high in installation and adjustment precision, and is high in installation and adjustment efficiency.

Description

technical field [0001] The invention relates to an assembly system and method for a multi-layer nested X-ray grazing incidence optical lens, belonging to the technical field of space optics. Background technique [0002] X-ray pulsar navigation is suitable for fully autonomous navigation of spacecraft in near-Earth space, deep space exploration, and interstellar flight. It can provide comprehensive navigation information such as position, velocity, attitude, and time for most space mission spacecraft, and realize the navigation of spacecraft. Completely autonomous navigation has the advantages of strong reliability, good stability, high accuracy, and wide applicability. It is a new type of autonomous navigation technology with great development potential, and it has extremely important engineering practical value and strategic research significance. [0003] The core of the X-ray pulsar navigation sensor is the X-ray optical lens. As a kind of X-ray optical lens, multi-laye...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G02B7/04G02B7/02

Inventor 左富昌梅志武石永强孙建波邓楼楼李连升王春宇

Owner BEIJING INST OF CONTROL ENG

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com