Adaptor of fiber interface

A fiber optic interface and adapter technology, which is applied in the field of industrial lasers, can solve the problems of poor dust-proof sealing performance, achieve the effects of lowering the overall temperature, improving dust-proof sealing performance, and reducing the risk of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

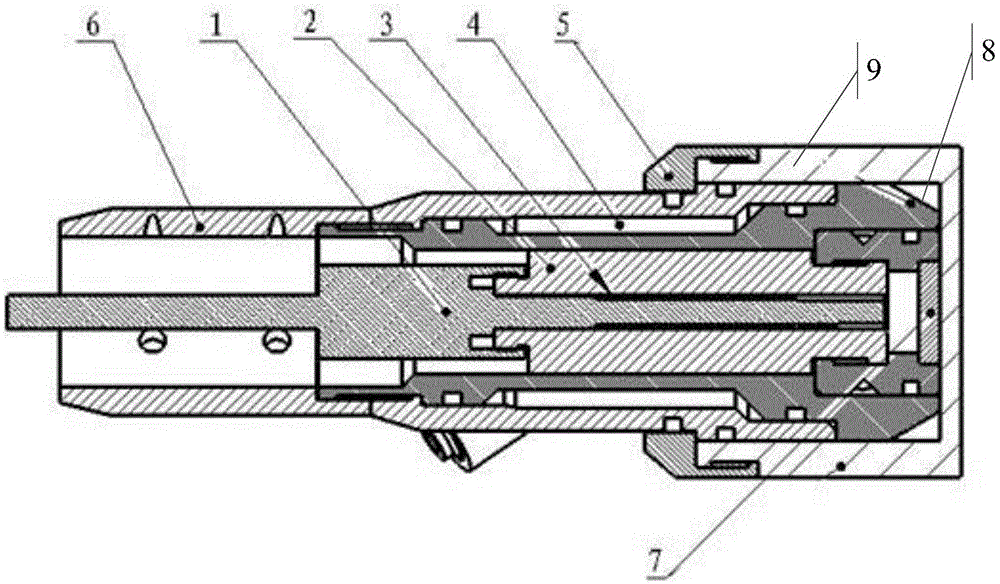

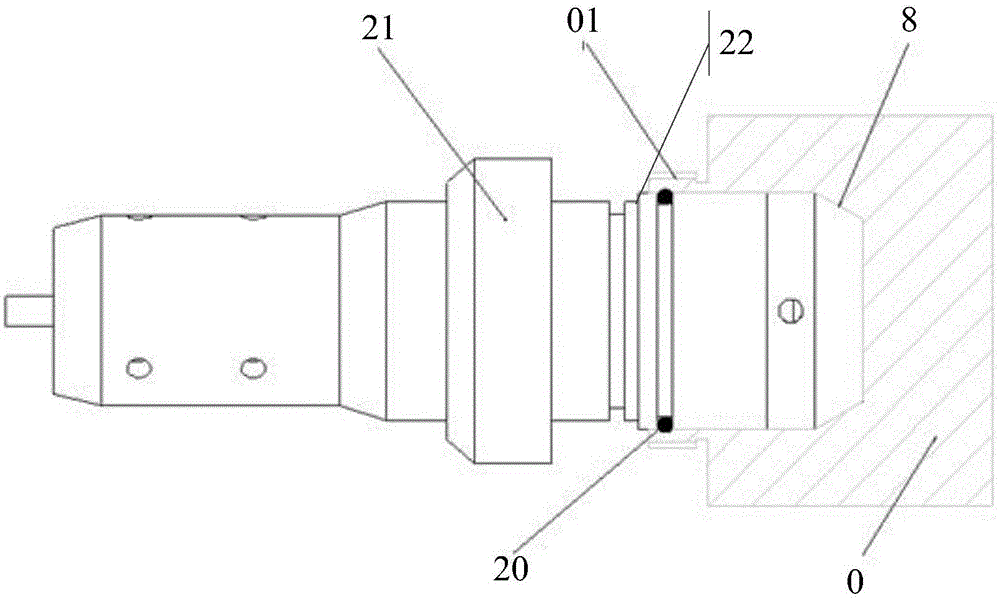

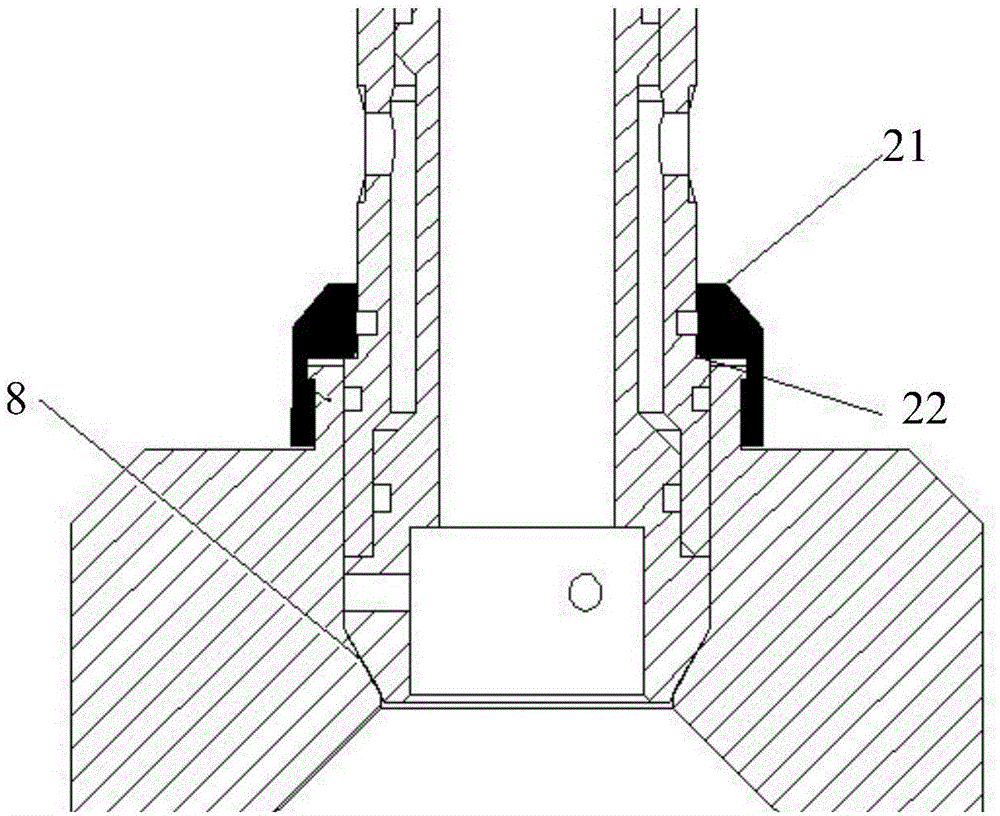

[0041] The invention provides an optical fiber interface adapter to solve the technical problem of poor dustproof and sealing performance of the optical fiber interface in the prior art.

[0042] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

[0043] Provided is an adapter for an optical fiber interface, comprising: an annular water-cooling structure, the annular water-cooling structure includes a water-cooling cavity inside for water circulation; a docking unit is arranged inside the annular water-cooling structure for connecting the optical fiber interface The locking mechanism is arranged at one end of the annular water-cooling structure, and is used to lock the adapter and the light output head; the first sealing ring is arranged inside the locking mechanism, and is used to seal the adapter and the light emitting head; Describe the interface between the optical hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com