Overlap joint type dustproof sealing strip

A dust-proof sealing and sealing strip technology, which is applied in the direction of sealing devices, etc., can solve the problems of poor dust-proof performance and difficulty in forming a seal, and achieve the effect of improving dust-proof sealing performance and increasing the sealing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

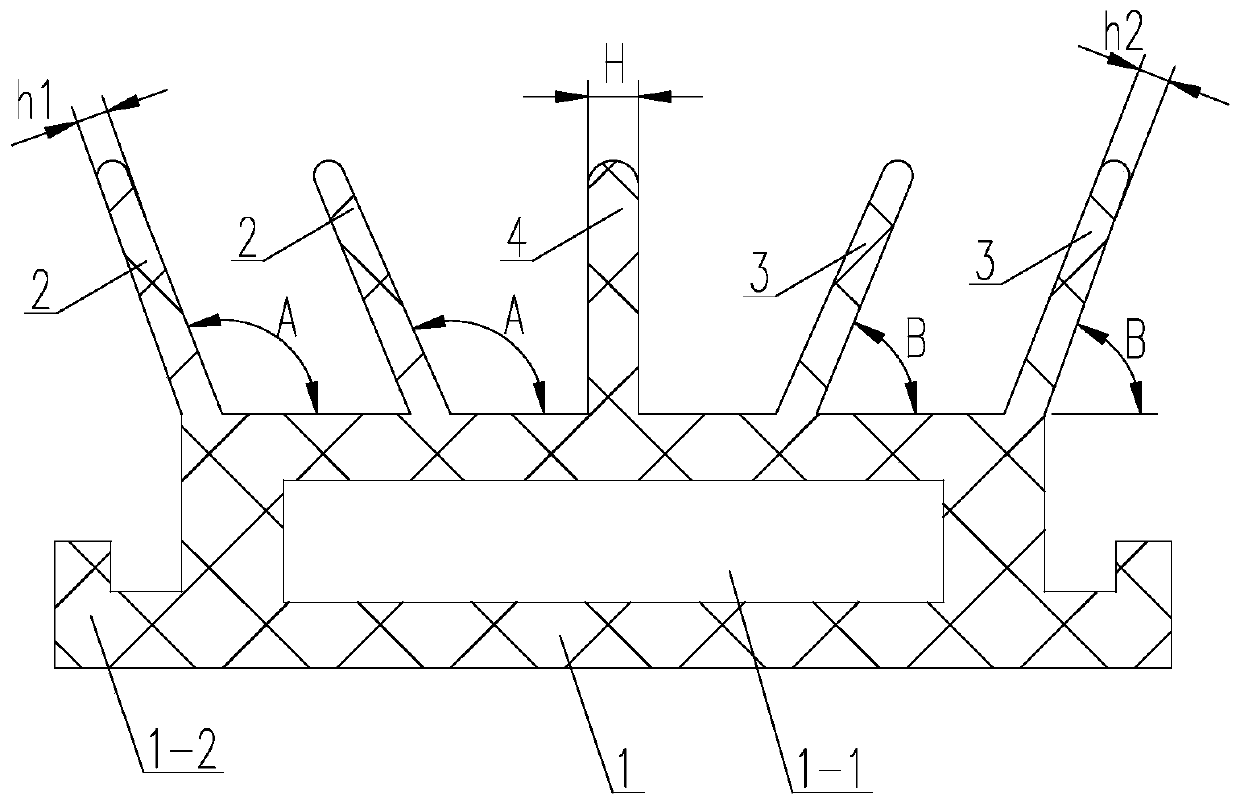

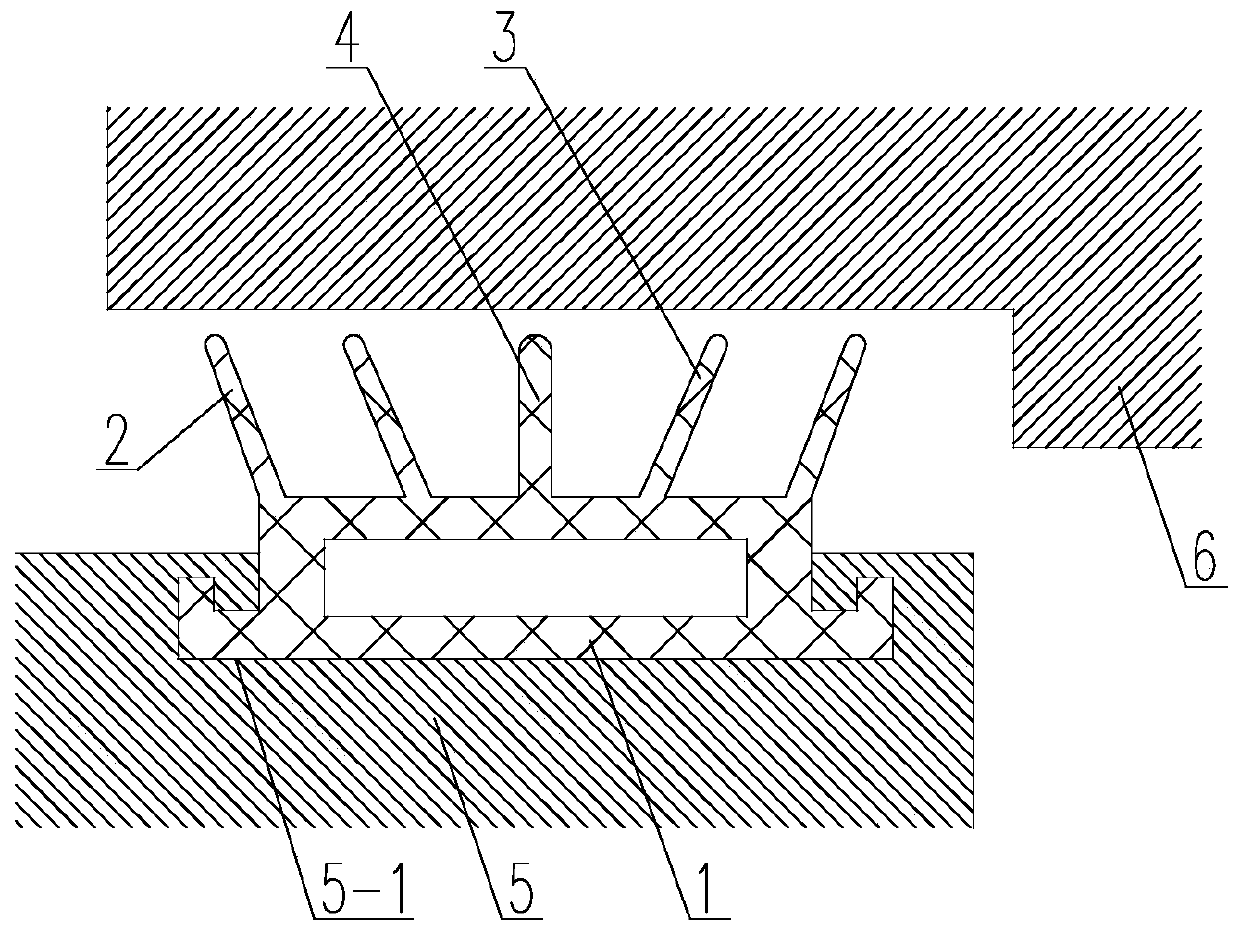

[0022] Example 1

[0023] Such as figure 1 As shown, a lap-type dust-proof sealing strip includes a sealing strip body 1. The left side of the upper end surface of the sealing strip body 1 is provided with at least two left dust-proof flaps 2 along its width direction. The right side of the upper end surface of the strip body 1 is provided with at least two right dust-proof fins 3 along its width direction. The left dust-proof fin 2 is inclined from bottom to top to the left. Tilt to the top to the right.

[0024] The included angle between the left dust-proof fin 2 on the left and the upper end surface of the weather strip body 1 among the two adjacent left dust-proof fins 2 A> the left dust fin 2 on the right and the weather strip body 1 The included angle A between the upper end faces facilitates that when the left dust-proof fin 2 is compressed, all the left dust-proof fins 2 easily present a structure that is pressed against one piece, which is similar to the domino effect, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com