A special light cone coated with nano film on the surface

A nano-film and light cone technology, which is applied in the field of optical passive devices, can solve the problems that the coupling efficiency is difficult to meet the actual needs, and achieve good light transmission performance, enhanced optical signal reception coupling efficiency, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

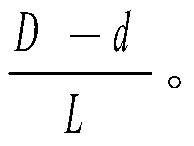

[0023] exist figure 1 In the schematic diagram of the front view section of a special light cone coated with nano-film on the surface, it is a solid special light cone made of Crown ordinary glass with a diameter of 60mm at the large end, a diameter of 10mm at the small end, and a length of 300mm. . Among them, the surface of the big end and the small end are respectively coated with a broadband anti-reflection nano-film with a thickness of 60nm in the 300-2000nm band, and the conical surface of the solid cone is coated with SiO with a thickness of 120nm. 2 / ZrO 2 Film system of high reflection nano film.

[0024] The broadband anti-reflection nano film in the above 300-2000nm band is made of Al with a purity of more than 99.99% 2 o 3 , MgF 2 、TiO 2 and SiO 2 Four kinds of coating materials, in terms of mass ratio Al 2 o 3 : MgF 2 : TiO 2 : SiO 2 =1:1:1:4, through the box-type vacuum coating machine (model ZZS660, manufacturer: Chengdu Nanguang Machinery Co., Ltd.,...

Embodiment 2

[0028] exist figure 1 In the schematic diagram of the front view section of a special light cone coated with nano-film on the surface, it is a solid special light cone made of Crown ordinary glass with a diameter of 60mm at the large end, a diameter of 10mm at the small end, and a length of 300mm. . Among them, the surface of the big end and the small end are respectively coated with a broadband anti-reflection nano film in the 300-2000nm band with a thickness of 450nm, and the conical surface of the solid cone is coated with SiO with a thickness of 900nm. 2 / ZrO 2 Film system of high reflection nano film.

[0029] The broadband anti-reflection nano film in the above 300-2000nm band is made of Al with a purity of more than 99.99% 2 o 3 , MgF 2 、TiO 2 and SiO 2 Four kinds of coating materials, in terms of mass ratio Al 2 o 3 : MgF 2 : TiO 2 : SiO 2 =1:1:1:4, through the box-type vacuum coating machine (model ZZS660, manufacturer: Chengdu Nanguang Machinery Co., Ltd....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com