Spray parameter test device

A technology of parameter testing and testing equipment, which is applied in the direction of measuring equipment and instruments, can solve problems such as environmental pollution, waste of resources, and inability to perform simple tests, and achieve the effects of reducing environmental pollution and avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

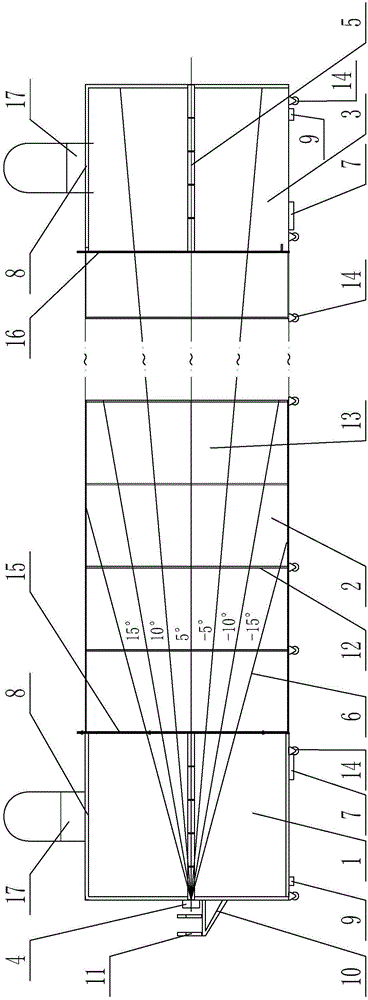

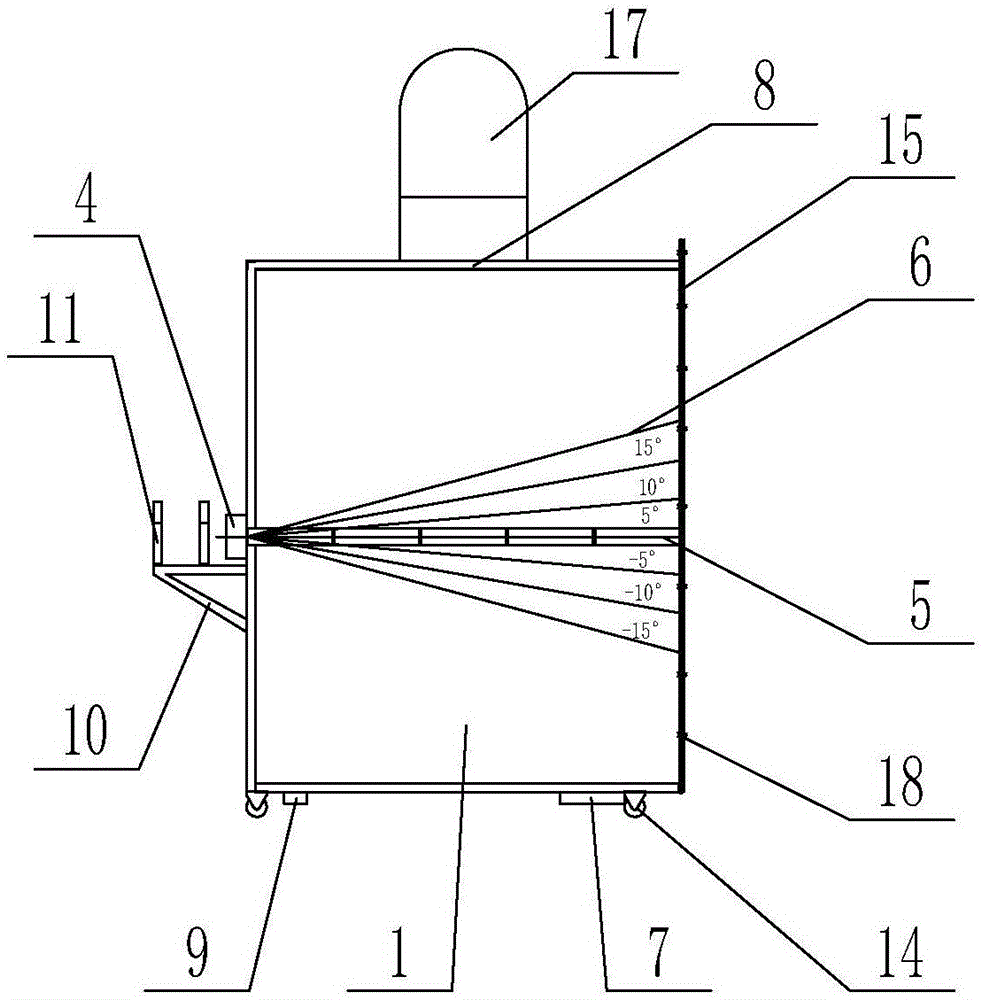

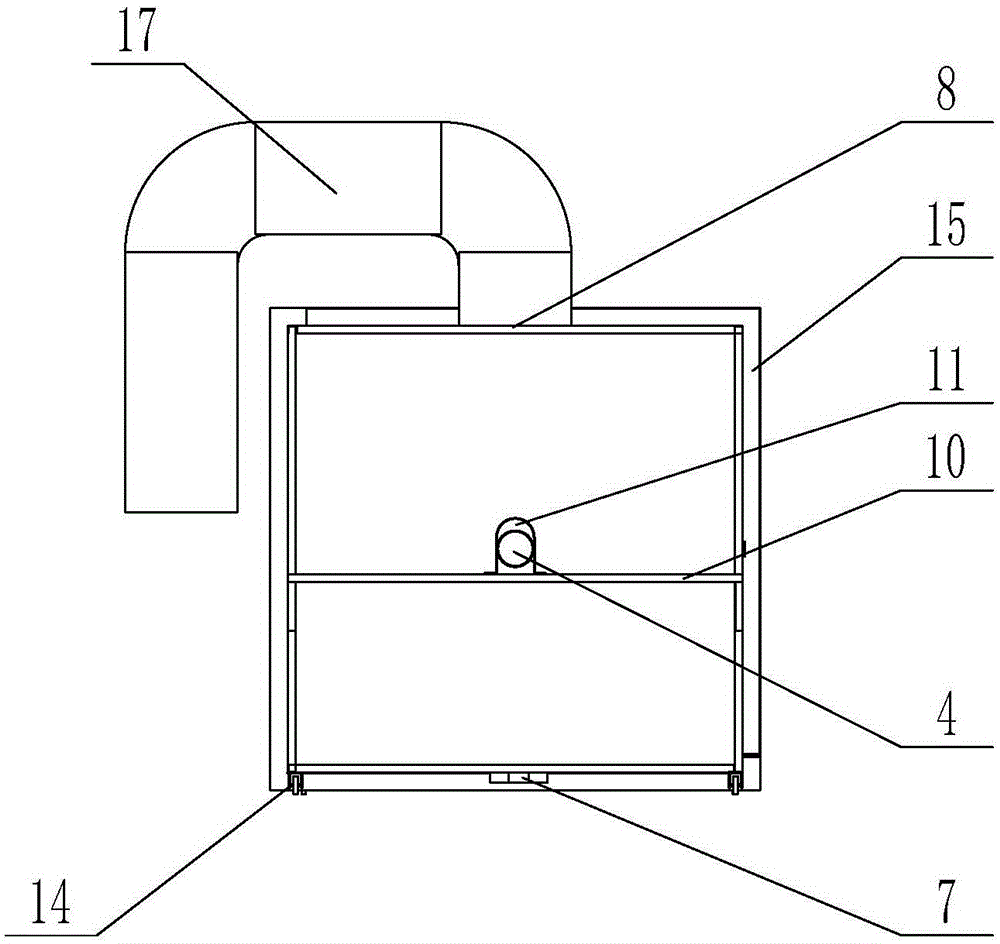

[0017] The spray parameter testing device of the present invention will be further described below in conjunction with the accompanying drawings and specific examples:

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the spray parameter testing device of the present invention comprises a left box body 1, a middle box body 2 and a right box body 3, and the left box body 1 and the right box body 3 are all made of hard transparent materials, such as acrylic plates, tempered glass, etc., as The purpose of using hard material for the box wall is not only for the shape of the equipment itself, but also to better withstand the weight and the impact of spraying. The role of transparency is to observe the spray situation inside the box more intuitively. The left end of the middle box body 2 is sealed connected with the right end of the left box body 1 through the first connecting flange 15 and bolts 18, and the right end of the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com