Threaded hole detection device

A detection device and threaded hole technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as difficult observation, internal thread detection is not easy to achieve, and difficult to detect, so as to facilitate focus assistance, reduce missed detection rate, Sample the full range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

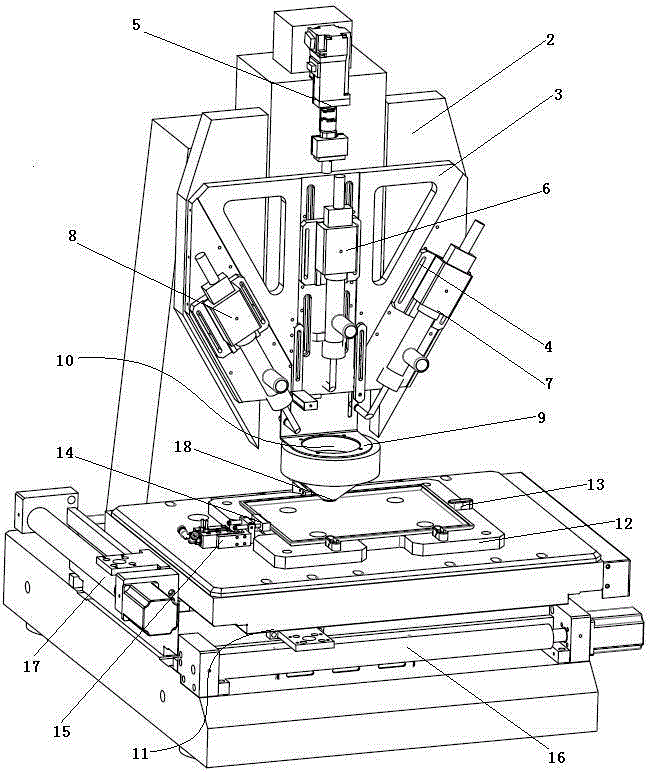

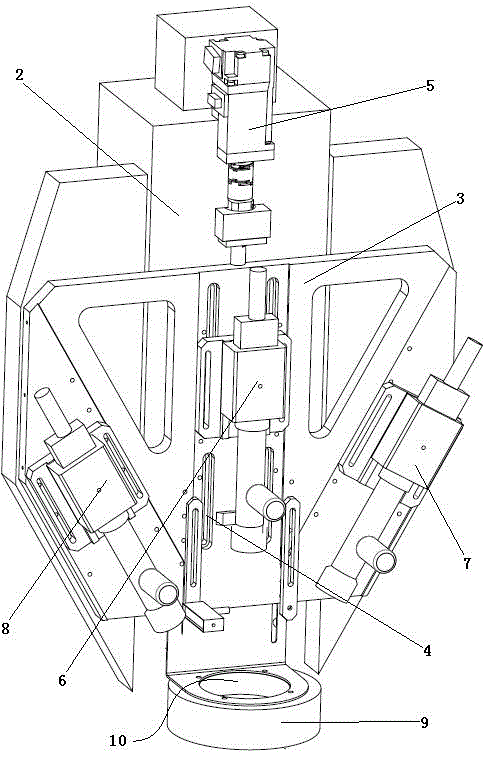

[0041] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

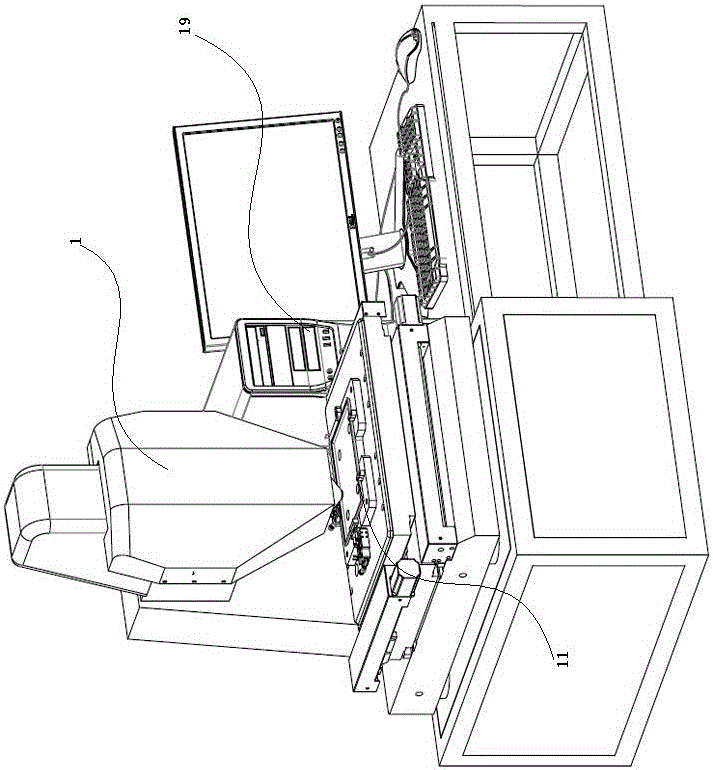

[0042] Such as Figure 1-4 As shown, a threaded hole detection device includes: an image detection mechanism 1 and a carrier table 11 disposed toward one side of the image detection mechanism 1, and an image device facing the carrier table 11 is provided on the image detection mechanism 1. And there are two imaging devices inclined toward the carrier table 11, which affect the movement between the detection mechanism and the carrier table 11, and the carrier table 11 can move in its plane. The imaging device is a CCD camera.

[0043] The CCD camera installed in the forward direction and the CCD camera installed in an inclined manner have a cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com