Shear wall with continuous zigzag tie bar structure

A zigzag and shear wall technology, applied to walls, building components, building structures, etc., can solve the problems of insufficient constraints of vertically distributed tendons, large steel consumption, and inability to improve the ductility of shear walls, etc., to achieve Low cost, improved ductility, and the effect of preventing steel bars from overturning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

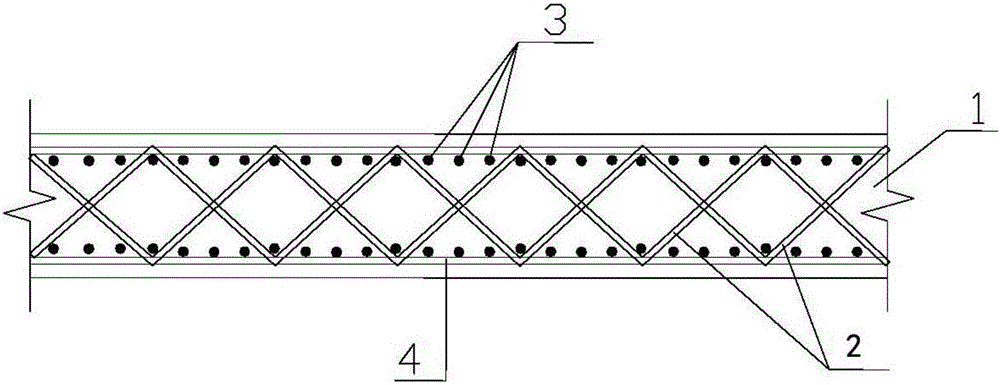

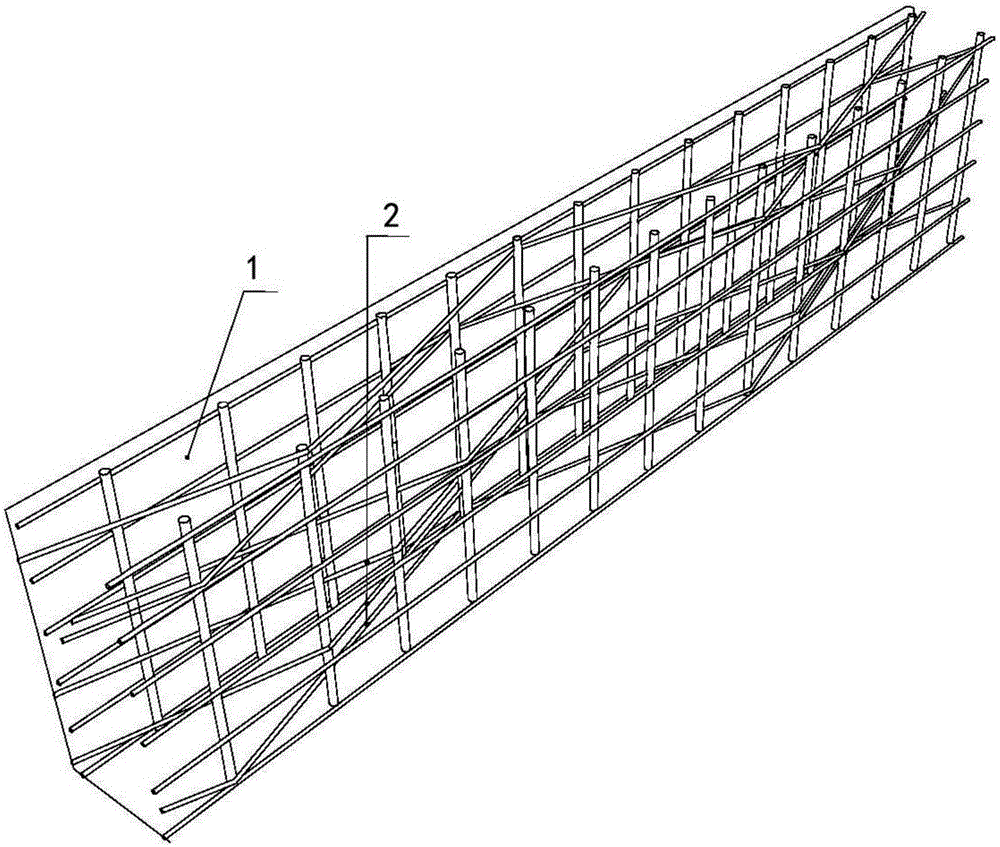

[0024] refer to Figure 1 to Figure 3 , this embodiment includes a concrete wall 1 and a steel bar structure built in the concrete wall 1, the steel bar structure is formed by connecting several tie bars 2, several vertically distributed bars 3 and several horizontally distributed bars 4, so The vertically distributed ribs 3 are vertically arranged in two rows in parallel, and the zigzag-shaped tendons 2 are arranged in the two rows of vertically distributed ribs 3 from top to bottom. 3 fixedly connected to form a three-dimensional frame structure; the horizontal distribution bars 4 are arranged on the outside or inside of the vertical distribution bars 3 from top to bottom, and one or more zigzag bars 2 are arranged The sharp points of 2 are fixedly connected with adjacent horizontal distribution ribs 4 to form a three-dimensional shear wall truss structure with one or more layers of horizontal frame structures.

[0025] In this example:

[0026] In the zigzag ties 2, in th...

specific Embodiment 2

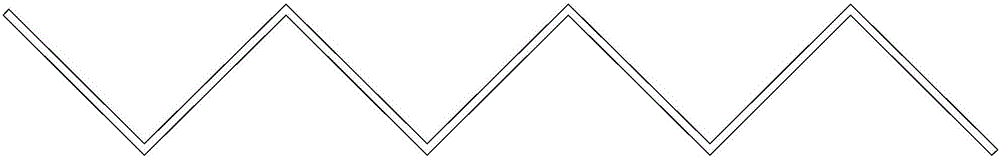

[0031] refer to Figure 4 The characteristics of the specific embodiment 2 of the present invention are: the zigzag-shaped tie bars 2 are composed of several sections of V-shaped tie bars, and the lengths of the two sides of each V-shaped tie bar meet the overlapping length, and are formed by welding or mechanical connection. Make each section of V-shaped tie bars form a continuous zigzag tie bar. Welding or mechanical connection is used to make each section of V-shaped tie bars form a continuous zigzag tie bar. All the other are with specific embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com