Adjustable one-way throttling device

A one-way throttling and adjustable technology, which is applied in water conservancy projects, artificial waterways, hydropower stations, etc., can solve the problems of hydraulic oil leakage environment, complexity, damage, etc., to adjust the closing speed, improve work efficiency, and combine Easy to debug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

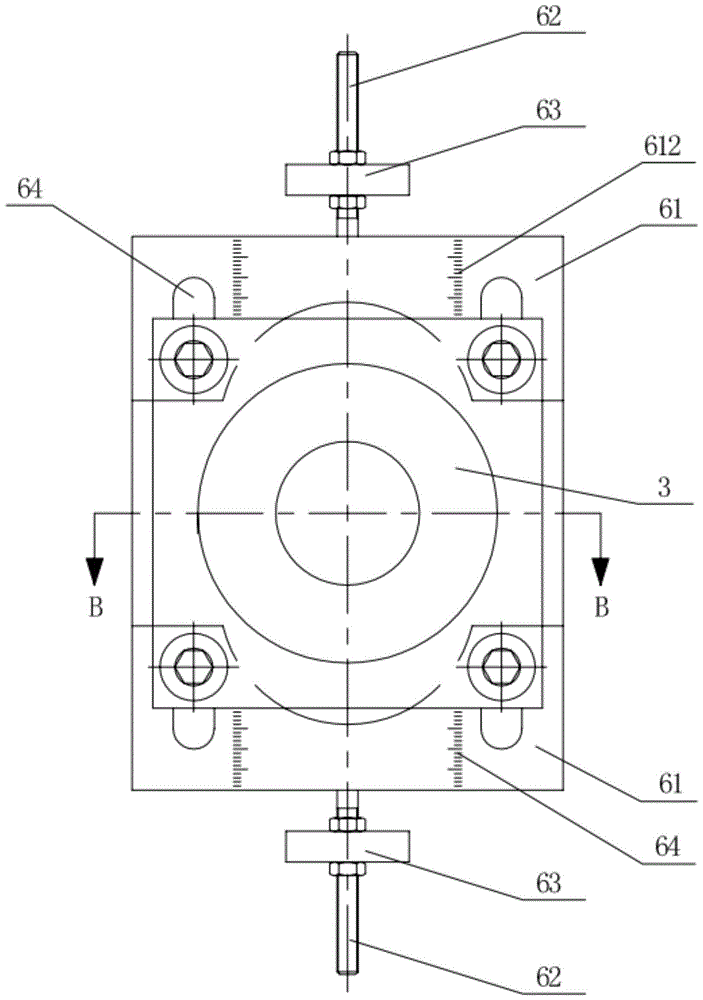

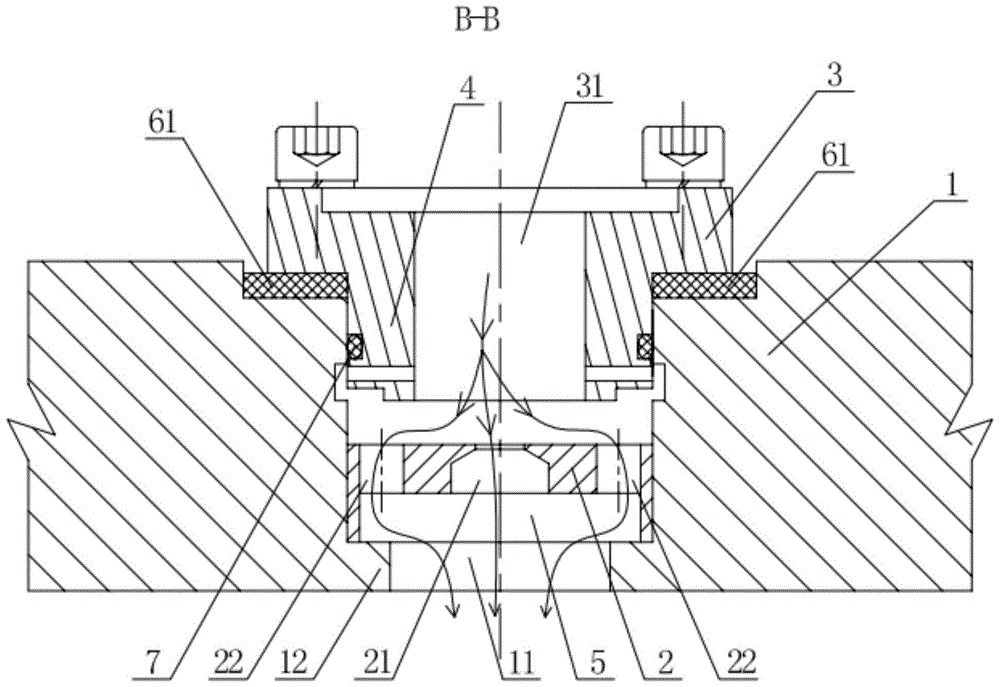

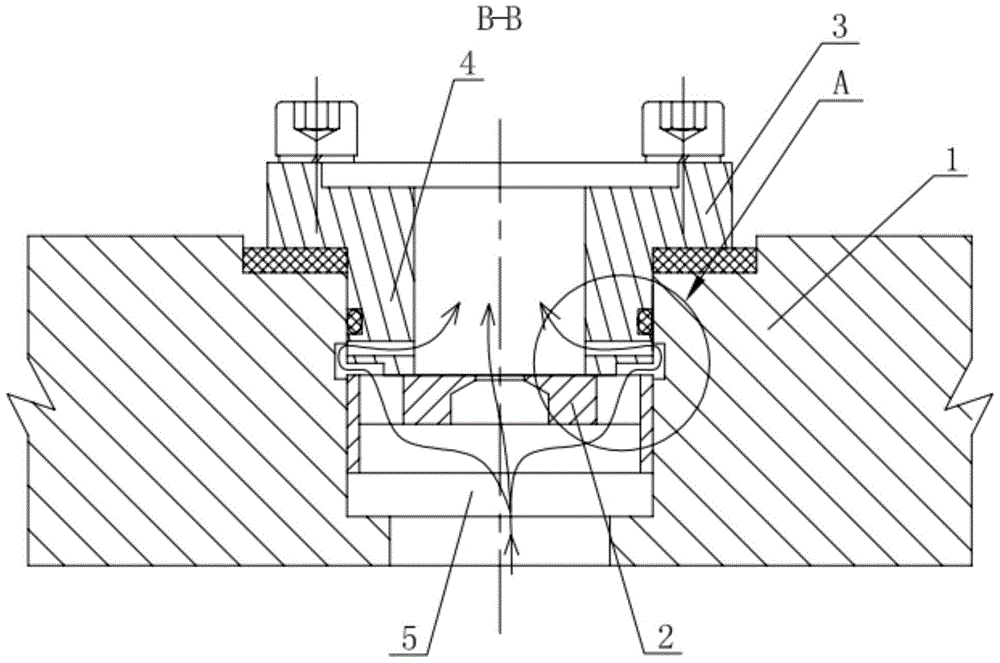

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0028] like Figure 1 to Figure 12 As shown in , the adjustable one-way throttling device of the present invention includes a lower end cover 1, a valve core 2 and a cover plate 3, and an installation through hole 11 is arranged on the lower end cover 1, and the bottom end of the installation through hole 11 A positioning step 12 is provided, the cover plate 3 has a convex cylinder 4, and a cover plate through hole 31 is arranged in the convex cylinder 4, and the convex cylinder 4 is sleeved in the installation through hole 11, and the convex cylinder A spool cavity 5 is formed between the bottom end surface of 4 and the positioning step 12; the spool 2 is set in the spool cavity 5 so that it can move up and down freely, and a base oil hole 21 is provided in the center of the spool 2 A decompression oil hole 22 is arranged on the periphery of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com