A crude oil decalcifier

A crude oil decalcifier and decalcifier technology, which is applied in the petroleum industry, refined hydrocarbon oil, etc., can solve the problems of low calcium removal rate and equipment corrosion of decalcifier, and achieve good thermal stability, reduce corrosion, and prepare simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

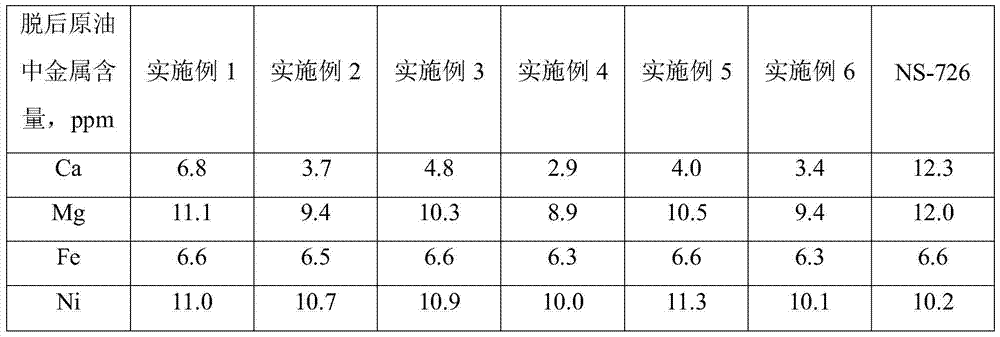

Examples

Embodiment 1

[0019] First, dissolve 2% sodium lactate and 70% lactic acid in water, then add 5% ammonium sulfate, stir until completely dissolved, then add 0.5% water-soluble imidazoline amide, and finally slowly add 0.1% cationic polyacrylamide, stir until completely uniform Phase aqueous solution, that is, crude oil decalcifier.

Embodiment 2

[0021] First, dissolve 2% sodium lactate and 85% lactic acid in water, then add 5% ammonium sulfate, stir until completely dissolved, then add 0.5% water-soluble imidazoline amide, and finally slowly add 0.1% cationic polyacrylamide, stir until completely uniform Phase aqueous solution, that is, crude oil decalcifier.

Embodiment 3

[0023] First, dissolve 2% sodium lactate and 70% lactic acid in water, then add 10% ammonium sulfate, stir until completely dissolved, then add 0.5% water-soluble imidazoline amide, and finally slowly add 0.1% cationic polyacrylamide, stir until completely uniform Phase aqueous solution, that is, crude oil decalcifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com