Extraction and purification method for Trollius chinensis polysaccharide and application thereof as tobacco humectant

A purification method, the technology of nasturtium, applied in the fields of tobacco, application, and tobacco treatment, can solve the problems of unsatisfactory humectants in cigarettes, achieve cheap and easy access to raw materials and reagents, reduce irritation and miscellaneous gases, and improve the extraction process The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

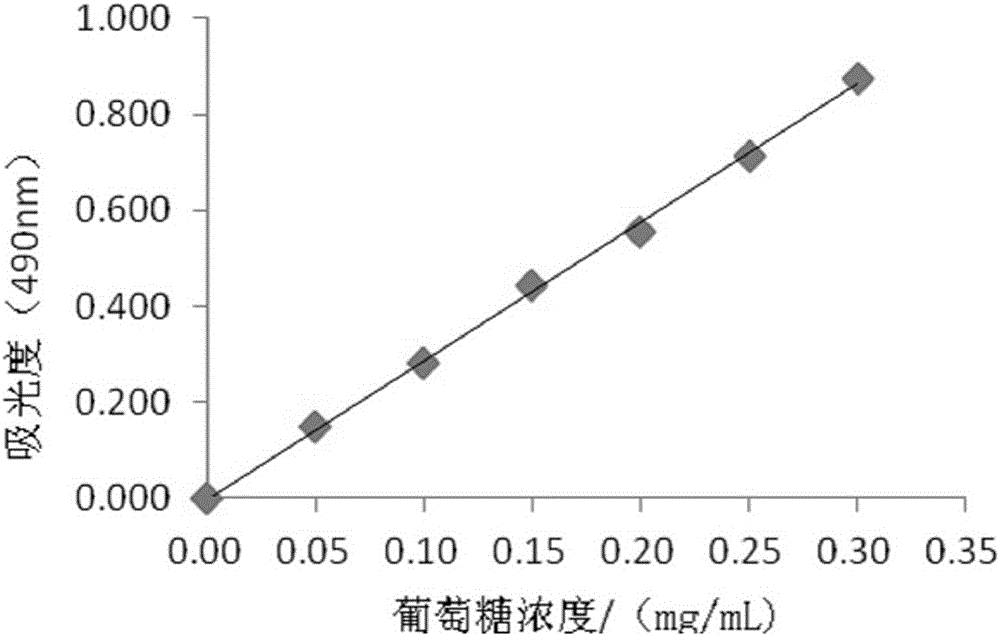

Image

Examples

Embodiment 1

[0047] b. Soaking: add 20 times the amount of water to the nasturtium powder obtained in step a, that is, the mass ratio of the nasturtium powder and water is 1:20, and soak for 2 hours at room temperature;

[0048] c. Enzyme treatment: heat the solution of nasturtium flower soaked in step b to 40° C., add cellulase for enzymolysis treatment for 2 hours, the amount of cellulase added accounts for 1.5% of the mass of nasturtium flower powder;

[0049] d. Ultrasonic extraction: Ultrasonic extraction is performed on the Trollius flower solution after enzymolysis in step c, the extraction temperature is 60°C, the ultrasonic extraction power is 300W, and the ultrasonic time is 10 minutes;

[0050] e. Solid-liquid separation: centrifuge the extract after ultrasonic extraction in step d, and centrifuge for 15 minutes at 2°C and 8000 rpm;

[0051] f. Concentrated alcohol precipitation: Concentrate the supernatant obtained after step e centrifugation under reduced pressure to 35% of th...

Embodiment 2

[0056] b. Soaking: add 22 times the amount of water to the nasturtium powder obtained in step a, that is, the mass ratio of the nasturtium powder and water is 1:22, and soak for 3 hours at room temperature;

[0057] c. Enzyme treatment: heat the solution of nasturtium flower soaked in step b to 45° C., add cellulase for enzymatic hydrolysis treatment for 1 hour, and the amount of cellulase added accounts for 2.0% of the mass of nasturtium flower powder;

[0058] d. Ultrasonic extraction: Ultrasonic extraction is performed on the Trollius flower solution after enzymolysis in step c, the extraction temperature is 70°C, the ultrasonic extraction power is 400W, and the ultrasonic time is 13 minutes;

[0059] e. Solid-liquid separation: centrifuge the extract after ultrasonic extraction in step d, and centrifuge for 15 minutes at 4°C and 9000 rpm;

[0060] f. Concentrated alcohol precipitation: Concentrate the supernatant obtained after step e centrifugation under reduced pressure ...

Embodiment 3

[0065] b. Soaking: add 25 times the amount of water to the nasturtium powder obtained in step a, that is, the mass ratio of the nasturtium powder and water is 1:25, and then soak for 4 hours at room temperature;

[0066] c. Enzyme treatment: heat the solution of nasturtium flower soaked in step b to 54° C., add cellulase for enzymatic hydrolysis treatment for 1 hour, and the amount of cellulase added accounts for 2.5% of the mass of nasturtium flower powder;

[0067] d. Ultrasonic extraction: Ultrasonic extraction is carried out on the Trollius flower solution after the enzymolysis in step c, the extraction temperature is 80°C, the ultrasonic extraction power is 500W, and the ultrasonic time is 10 minutes;

[0068] e. Solid-liquid separation: centrifuge the extract after ultrasonic extraction in step d, and centrifuge for 10 min at 6°C and 10,000 rpm;

[0069] f. Concentrated alcohol precipitation: Concentrate the supernatant obtained after step e centrifugation under reduced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com