Method for preparing fertilizer by using organic solid waste

A technology for the preparation of organic solids and fertilizers, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of biological organic parts. It can solve the problems of difficult to achieve environmental protection treatment and resource utilization of organic solid waste, and high investment costs in fixed assets. The effect of secondary environmental pollution problems, significant ecological benefits, and low processing and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

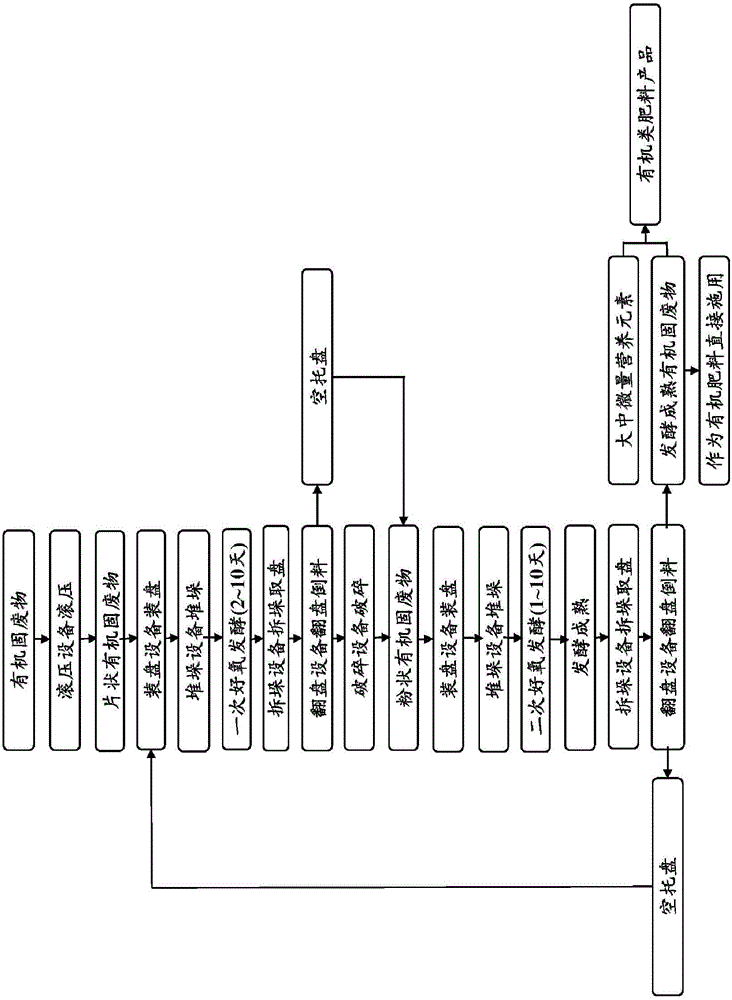

[0045] see figure 1 Shown is the process flow diagram of Embodiment 1 of the method for preparing fertilizer from organic solid waste in the present invention. In this example, the method of using organic solid waste to prepare fertilizer is to roll the sugar filter sludge with a water content of 75% into a pan with a size of 3500mm in length, 2000mm in width, and 350mm in height, and the bottom and surrounding areas are uniform. In the air-permeable fermentation tray, the fermentation trays containing the sugar filter mud are stacked into stacks for aerobic fermentation for 20 days, and after they are decomposed and dried into decomposed organic materials with a water content of less than 40%, they are mixed with large, medium and trace amounts required by plants. Nutrient elements are combined to produce organic-inorganic compound fertilizer products. Its production steps are as follows:

[0046] Step 1, the above-mentioned sugar refining filter mud with a water content of...

Embodiment 2

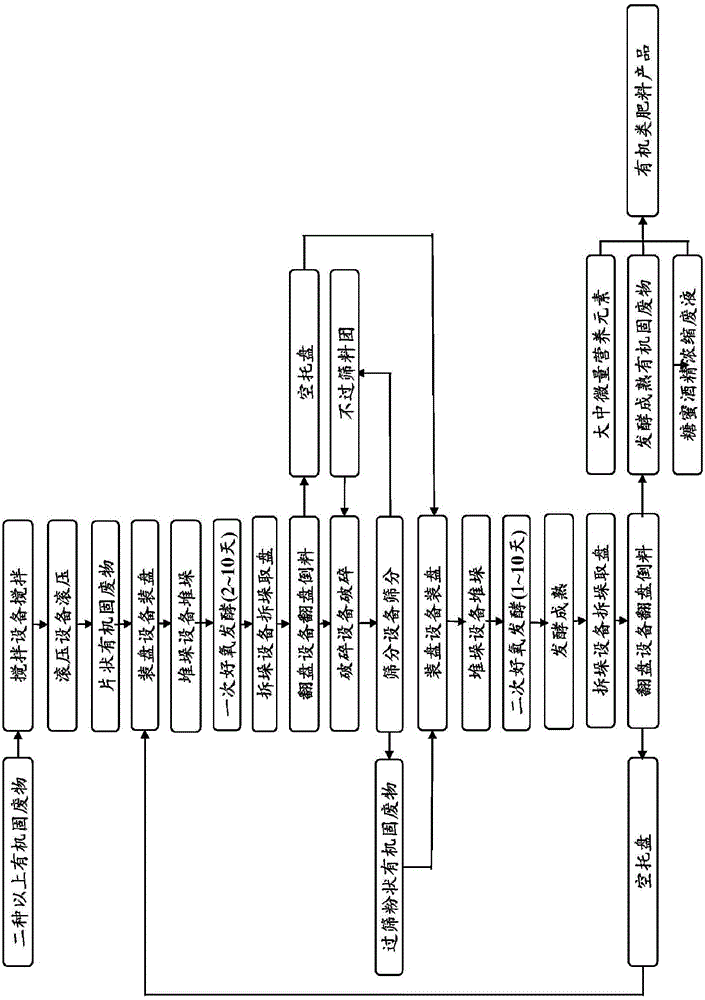

[0056] see figure 2 Shown is the process flow diagram of Embodiment 2 of the method for preparing fertilizer from organic solid waste in the present invention. In this example, the method of using organic solid waste to prepare fertilizer is to mix sugar filter mud with a water content of 70% and bagasse / pith with a water content of 45% to adjust the water content to 67.5%, and after rolling, put the The inner size of the tray is 2000mm in length, 1200mm in width, 200mm in height, and the bottom and surrounding sides of the fermentation tray are air-permeable, and then the fermentation trays containing sugar filter mud and bagasse / pith mixture are stacked into trays for aerobic fermentation for 12 days After being decomposed and dried into decomposed organic material with a water content of less than 25%, it is combined with large, medium and micronutrient elements required by plants to produce organic-inorganic compound fertilizer products. Its production steps are as follo...

Embodiment 3

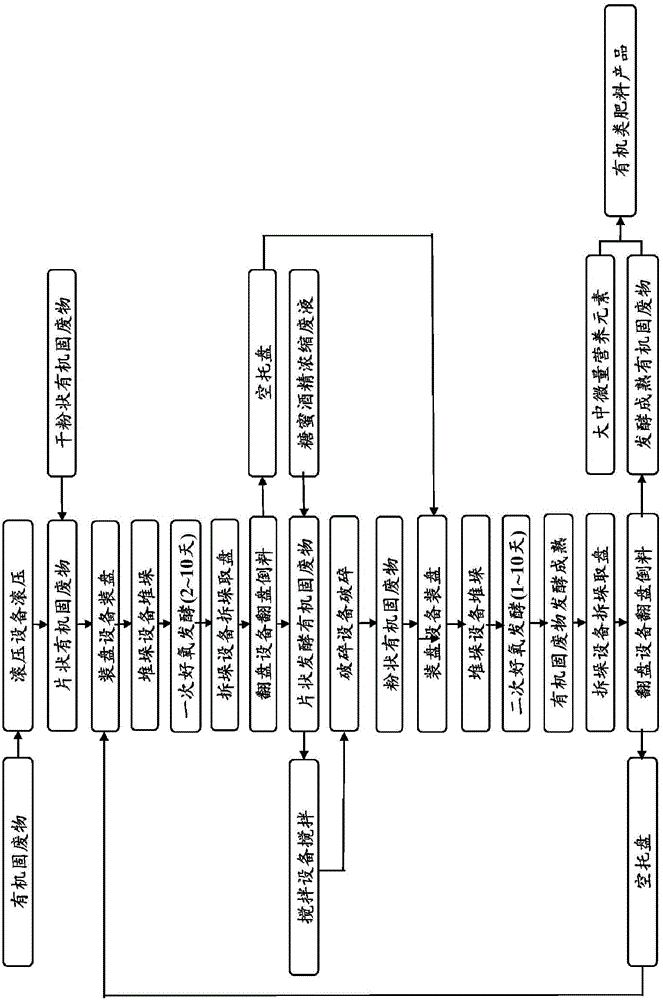

[0068] see image 3 Shown is the process flow diagram of Embodiment 3 of the method for preparing fertilizer from organic solid waste in the present invention. In this embodiment, the method of utilizing organic solid waste to prepare fertilizer is to roll the sugar filter mud with a water content of 70%, and then sprinkle and mix dry powdered sugar filter mud on the surface of the sugar filter mud (fermentation reuse) material), put it into a fermentation tray with a length of 1000mm, a width of 300mm, and a height of 100mm, and the bottom and surrounding sides of the fermentation tray are all ventilated, and then the fermentation trays containing the sugar filter mud are stacked for a total of 3 days. After primary aerobic fermentation and secondary aerobic fermentation, after decomposing and drying into decomposed organic material with a water content of less than 30%, it is combined with large, medium and micronutrient elements required by plants to produce organic-inorgan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com