Particle shaping method for machine-made aggregate

A kind of aggregate and mechanism technology, applied in the field of particle shaping of machine-made aggregates, can solve the problem that the content of needle flake particles has little effect, and achieve the effect of reducing the content of needle flake particles and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] After a natural rock is crushed and coarsely screened by a jaw crusher, natural machine-made coarse aggregate with a nominal particle size of 5-40 mm and machine-made sand with a nominal particle size of less than 5 mm are obtained, and then the aggregate particle size is determined by the distance between the rollers The upper limit of the roller press is used for shaping treatment, that is, when the coarse aggregate is rolled and shaped, the distance between the rollers is 40mm, and when the machine-made sand is rolled and shaped, the distance between the rollers is 5mm, and the shaped coarse aggregate and machine-made sand are further screened deal with.

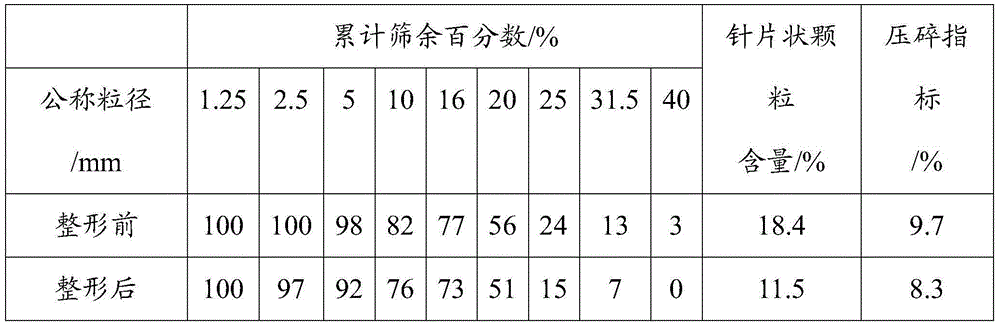

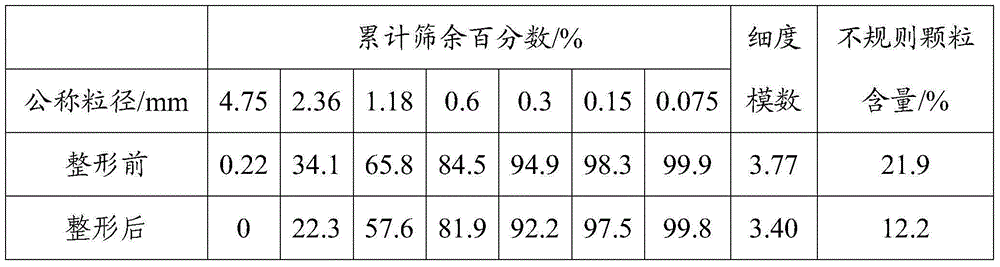

[0020] According to "Gravel and Pebble for Construction" GBT14685-2011, the coarse aggregate before and after plastic treatment is tested for particle size distribution, needle flake particle content and crushing index. The test results are shown in Table 1-1. It can be seen from Table 1-1 that after plastic treatm...

Embodiment 2

[0027] After the waste concrete is crushed and coarsely screened by a jaw crusher, the recycled mechanism coarse aggregate with a nominal particle size of 5 to 40mm and the recycled mechanism fine aggregate with a nominal particle size of less than 5mm are obtained, and then the aggregate is obtained by using the roller spacing respectively. The roller press with the upper limit of the particle size is used for shaping treatment, that is, when the coarse aggregate is rolled and shaped, the roller spacing is 40mm, and when the fine aggregate is rolled and shaped, the roller spacing is 5mm, and the coarse and fine aggregates after shaping Further screening is carried out.

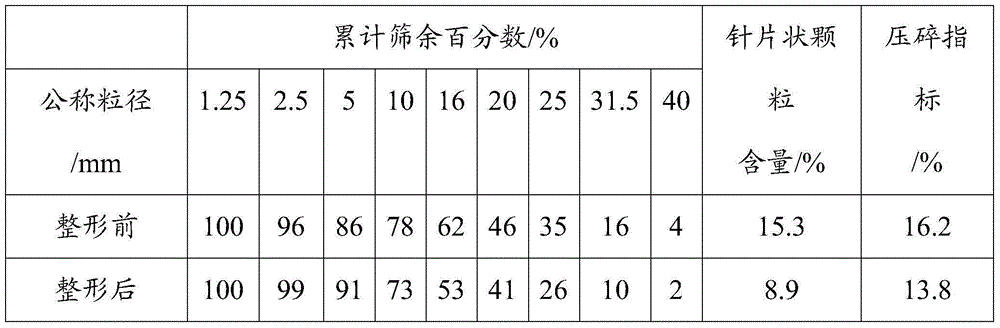

[0028] According to "Gravel and Pebble for Construction" GBT14685-2011, the coarse aggregate before and after shaping treatment is tested for particle gradation, needle-like particle content and crushing index. The test results are shown in Table 2-1. It can be seen from Table 2-1 that after plastic treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Nominal particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com