Livestock feed casting test stand

A test bench and livestock technology, applied in loading/unloading, conveyor, transportation and packaging, etc., can solve the problems of unreasonable feeding amount, unreasonable feeding, uneven feeding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

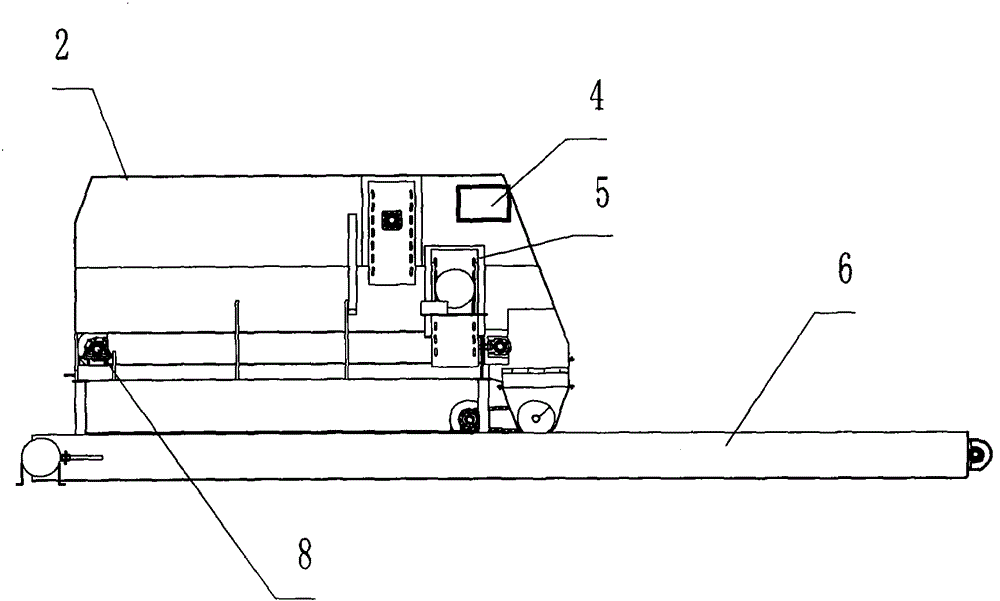

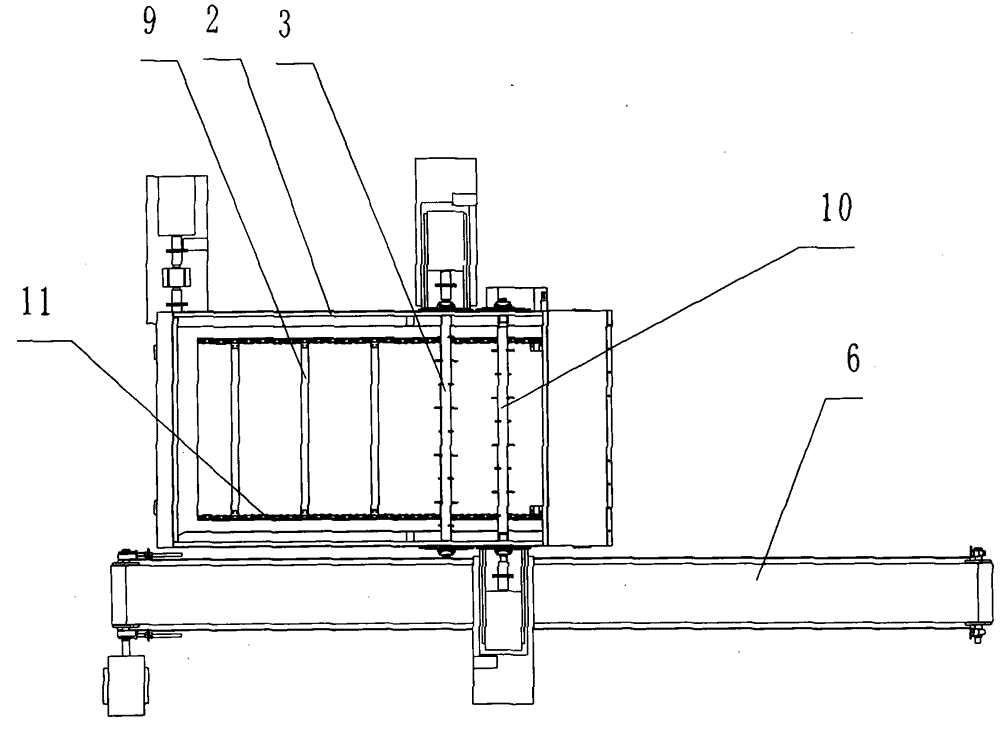

[0017] Embodiment: refer to attached Figure 1-7 , this embodiment includes a support frame 1, the support frame 1 is provided with a material box 2, the material box 2 is provided with a scraper 9, and the two ends of the scraper 9 are provided with a transmission chain 11, The transmission chain 11 is provided with a transmission chain ear, and the scraper 9 is connected with the transmission chain ear by screws, and the distance between the scraper 9 is provided, and the distance between the scraper 9 can be passed Select different distance transmission chain ears to adjust, the transmission chain 11 is provided with a driving sprocket and a driven sprocket, the driving sprocket is provided with a scraper conveyor drive shaft 8, and the scraper conveyor The driving shaft 8 is provided with a scraper conveyor torque sensor, the scraper conveyor motor is provided with a scraper conveyor motor, and the scraper conveyor motor is provided with a scraper conveyor frequency conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com