Loading and unloading system for distribution center type automated container terminal

A loading and unloading system and distribution center technology, applied in storage devices, transportation and packaging, etc., can solve the problems of high cost of single equipment, difficult to many to one, high anti-shake requirements, etc., to improve operating efficiency and reduce the number of magnetic points , the effect of fast running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

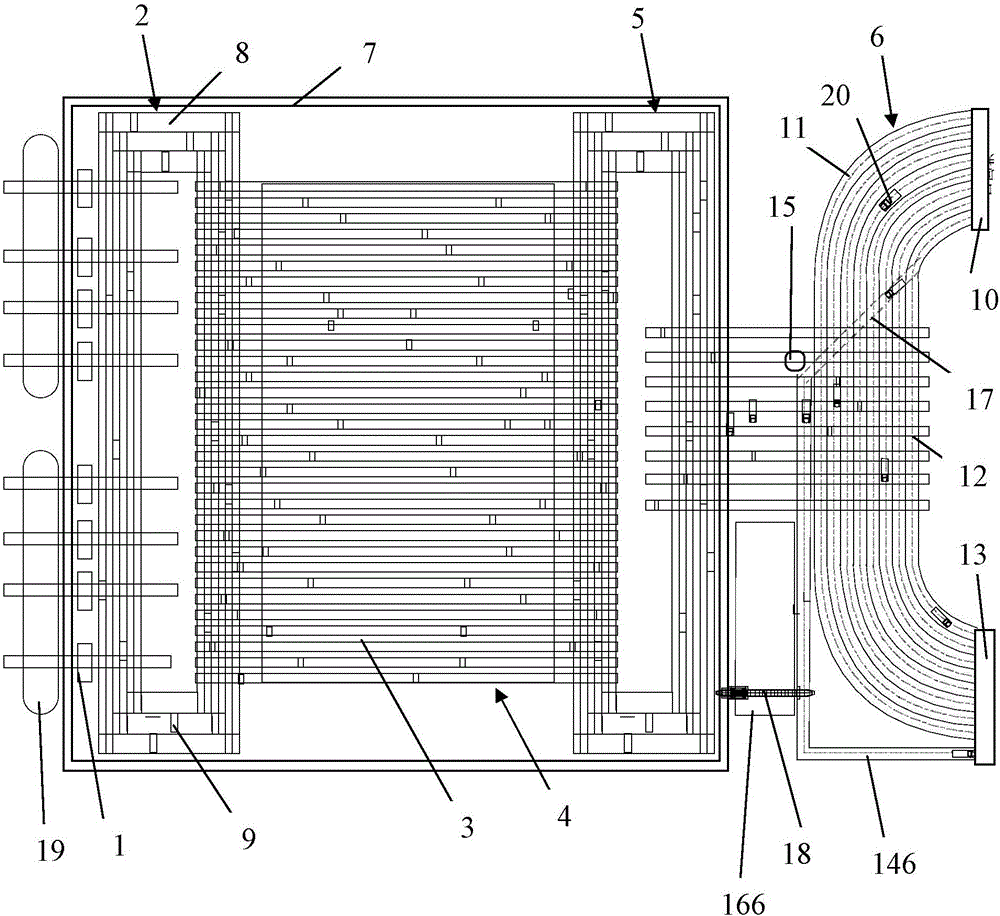

[0026] The distribution center type automated container terminal loading and unloading system provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] Such as figure 1 As shown, the distribution center-type automated container terminal loading and unloading system provided by the present invention includes a plurality of quay cranes 1, a multi-way back-shaped automatic transport system 2 near the shore, an elevated container automatic loading and unloading system 3, a storage yard 4, and multiple Road-back zigzag automatic transportation system 5, collection and distribution port transportation system 6, circular special box channel 7 and control system;

[0028] Among them, a plurality of quay cranes 1 are set along the track along the shore. Each quay crane 1 includes a transfer platform, a main trolley and a fully automatic auxiliary trolley. For transfer, the automatic auxiliary tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com