Circular rotating mechanism of vacuum tube

A technology of a rotating mechanism and a vacuum tube, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problem of not being able to rotate for one week or even more, and achieve the effect of simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

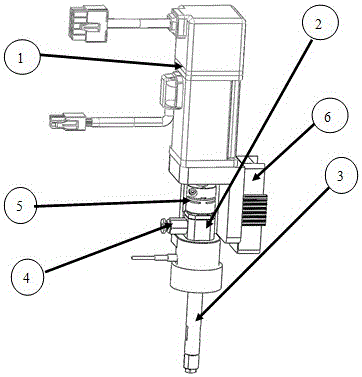

[0013] The present invention will be further described below in conjunction with accompanying drawing.

[0014] The vacuum tube circular rotation mechanism includes a motor 1, a sealing and fixing block 2, a vacuum tube body 3, a vacuum joint 4, a coupling 5, and a fixing seat 6, and is characterized in that the vacuum tube body 3 is arranged under the coupling 5 through the sealing and fixing block 2, The inside of the vacuum tube body 3 is connected to the negative pressure device through the vacuum joint 4 arranged on one side of the sealing fixed block 2, the coupling 5 is arranged on the output end of the motor 1, and the motor 1 is arranged above the fixed seat 6 and connected with the fixed seat 6, The sealing and fixing block 2 is connected with the fixing seat 6 . The section of the fixing seat 6 is in the shape of "7". The output end of the motor 1 is a rotary output. A suction nozzle is arranged below the vacuum tube body 3 .

[0015] In the present invention, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com