Electric horizontal type pipe cutting machine for plastic pipes

A pipe cutting machine and pipe-use technology, which is applied in metal processing and other directions, can solve the problems that the pipe cannot be fixed well, the pipe cutting machine is bulky, and cannot adapt to the pipe, etc., and achieves the effect of compact structure, low price, and guaranteed cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

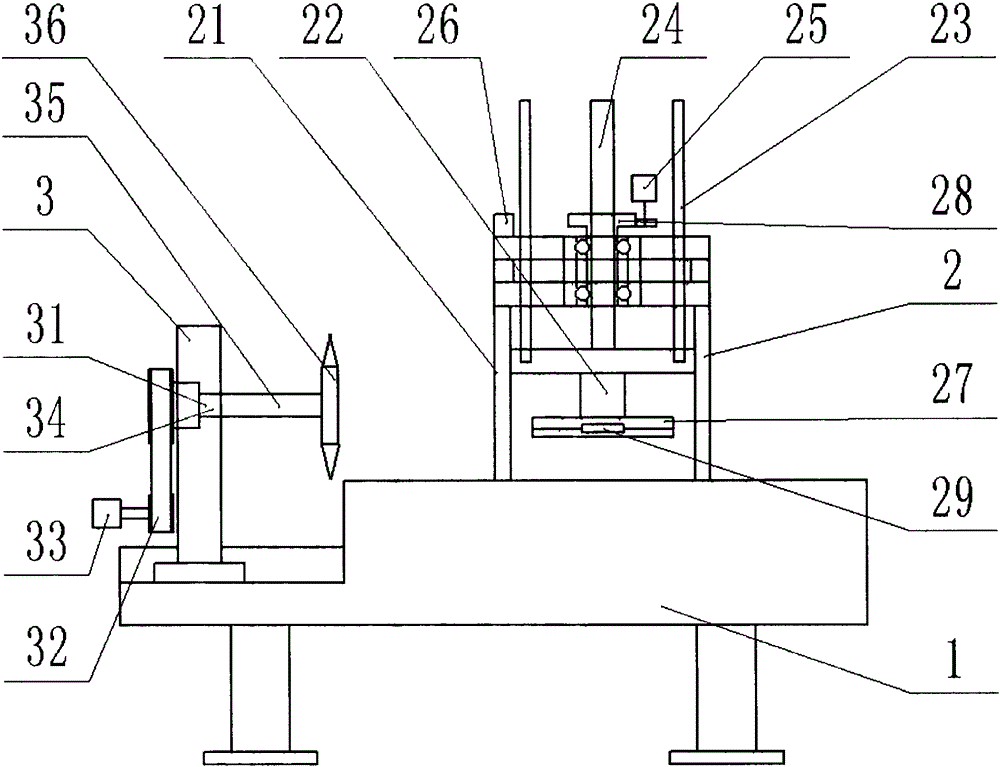

[0013] see figure 1 , an electric horizontal pipe cutting machine for plastic pipes, comprising a frame body 1, a clamping mechanism 2 and a pipe cutting mechanism, the clamping mechanism 2 and the pipe cutting mechanism are arranged on the frame body 1, the clamping mechanism 2 supports 21, Push rod 22, polished rod 23, leading screw 24, first motor 25, controller 26, tight lock seat 27, drive cover 28 and sensor 29; Described support 21 is provided with first motor 25, and the front end of first motor 25 is connected There is a drive sleeve 28, the push rod 22 is connected with a lead screw 24 and a polished rod 23, the lead screw 24 and the polished rod 23 are connected with the support 21, the drive sleeve 28 is sleeved on the lead screw 24, and the front end of the push rod 22 is connected with a tight Lock seat 27 and sensor 29, controller 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com