Repair welding tool for oil storage barrel assembly

A technology for oil storage tanks and components, which is applied in the field of repair welding tooling for oil storage tank components, which can solve problems such as virtual welding, low welding strength, and easy disassembly, and achieve the effects of convenient operation, simple structure, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

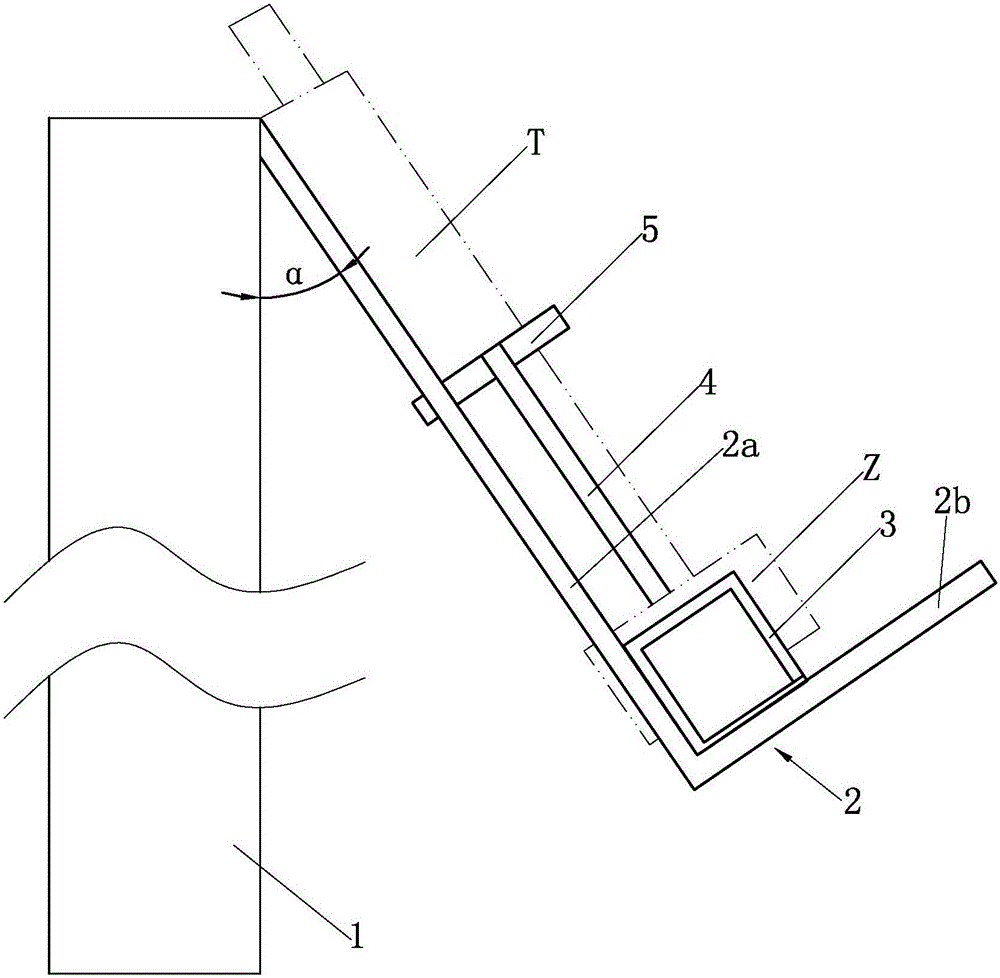

[0012] Such as figure 1 As shown, a repair welding tool for an oil storage cylinder assembly is mainly composed of a welding table 1, a rectangular rod 2, a supporting square steel 3, a round rod 4 and a rectangular frame 5. Wherein, the welding table 1 is welded by angle steel, and the height of the welding table 1 is 1.1-1.4m, and can be further preferably 1.2, 1.3m.

[0013] There are two right-angled rods 2 side by side at the front of the welding table 1, and the right-angled rods 2 are composed of a first round rod 2a and a second round rod 2b, wherein the upper end of the first round rod 2a is in contact with the front part of the welding table 1. For welding, the first round bar 2a is set forward, and the lower end of the first round bar 2a is vertically fixed to the lower end of the second round bar 2b, and the upper end of the second round bar is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com