Microstructure device adopting series amplification

A series structure and microstructure technology, applied in the direction of mixers, dissolution, chemical instruments and methods, etc., can solve the problems of poor operation stability, complex fluid flow distribution, and high requirements for the manufacturing process of parallel devices, so that it is not easy to block and make The effect of convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

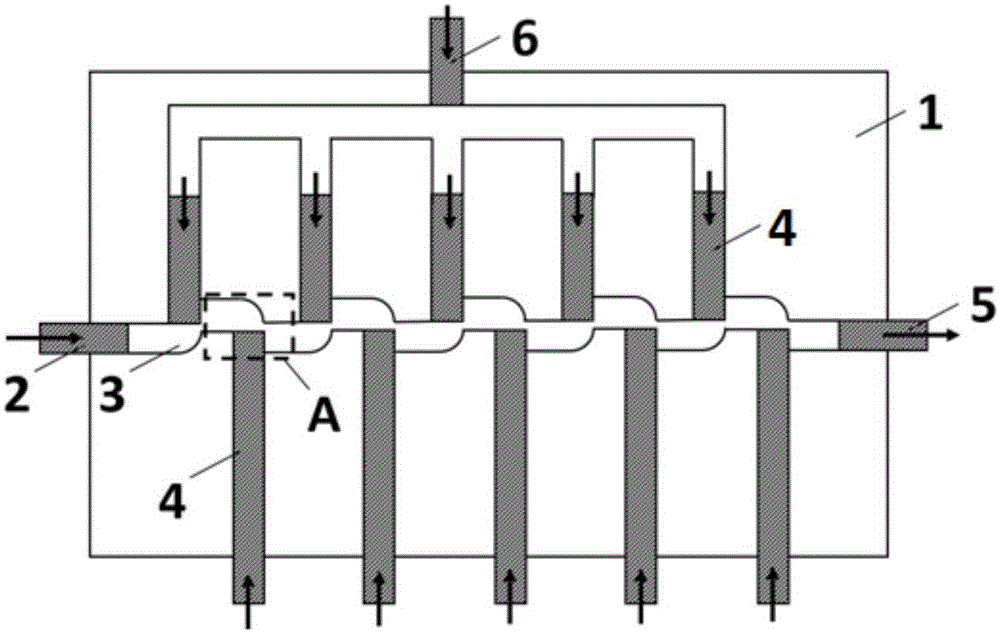

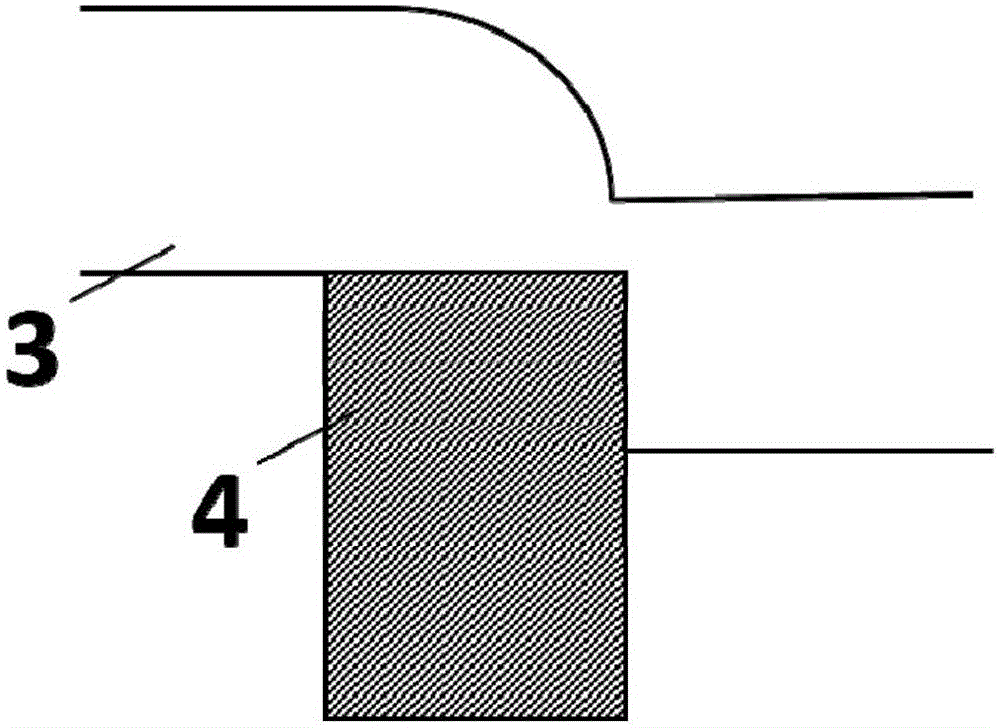

[0028] Polymethyl methacrylate (PMMA) is used as the material of the microchannel substrate 1. The width and depth of the main channel 3 are both 750 microns, and the width and depth of the bypass channel 4 are both 750 microns. The main channel 3 and the bypass channel 4 are rectangular channels. The radial width of the constriction is 200 microns, and the main channel 3 has ten stages of constriction, and the constriction interval is 1500 microns. A flat quartz capillary with an outer diameter of 750 microns and an inner diameter of 530 microns is embedded in the bypass channel 4 , and the front end is flush with the upper side wall of the upstream main channel 3 . channel structure like figure 1 As shown, both sides of the main channel 3 adopt the dispersed phase injection method ( figure 1 upper structure).

[0029] The continuous phase was injected using Teflon tubing and the two-phase fluid was collected. Add sodium dodecyl sulfate sodium sulfate (SDS, 0.01wt%-2wt%) ...

Embodiment 2

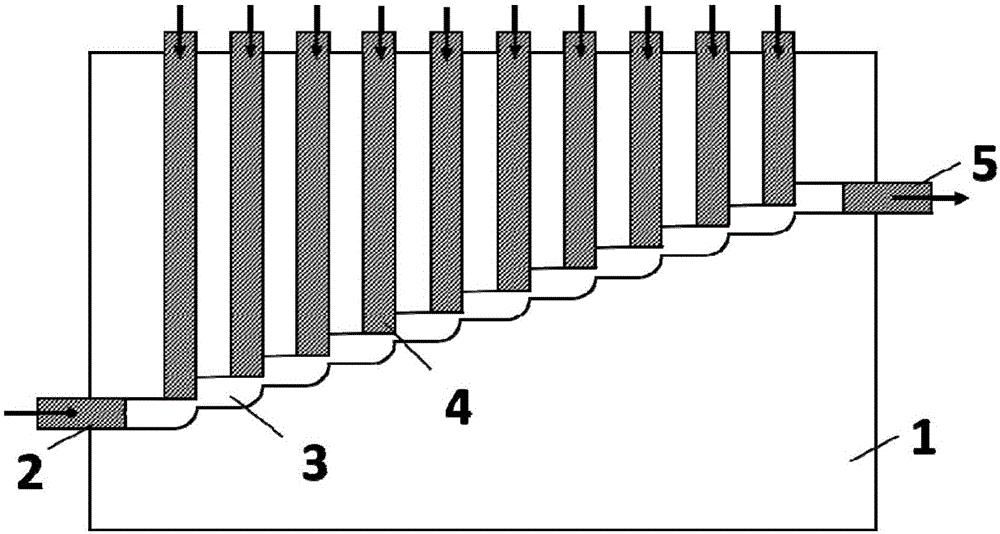

[0031] Stainless steel is used as the material of the microchannel substrate 1. The width and depth of the main channel 3 are both 300 microns, and the width and depth of the bypass channel 4 are both 300 microns. Both the main channel 3 and the bypass channel 4 are rectangular channels. The radial width of the constriction is 10 microns, and the main channel 3 has ten stages of constriction at intervals of 500 microns. A flat stainless steel capillary with an outer diameter of 300 μm and an inner diameter of 50 μm is embedded in the bypass channel 4 , and the front end of the capillary is flush with the upper side wall of the upstream main channel 3 . channel structure like image 3 As shown, the upper side of the main channel 3 adopts the mode of direct injection to inject the dispersed phase into the main channel 3 ( image 3 upper structure).

[0032] The continuous phase was injected using Teflon tubing and the two-phase fluid was collected. Add sodium dodecyl sulfate ...

Embodiment 3

[0034] Using polytetrafluoroethylene as the material of the microchannel substrate 1, the width and depth of the main channel 3 are both 1300 microns, the width and depth of the bypass channel 4 are both 1300 microns, and both the main channel 3 and the bypass channel 4 are rectangular channels . The radial width of the constriction is 300 microns, and the main channel 3 has ten stages of constriction at intervals of 5000 microns. A stainless steel capillary with an outer diameter of 1300 μm and an inner diameter of 1000 μm is embedded in the bypass channel 4 , and the front end of the capillary is flush with the upper side wall of the upstream main channel 3 . channel structure like image 3 As shown, the upper side of the main channel 3 adopts the mode of direct injection to inject the dispersed phase into the main channel ( image 3 upper structure).

[0035] The continuous phase was injected using Teflon tubing and the two-phase fluid was collected. Add sodium dodecyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com