Electrolyte solutions for high energy cathode materials and methods for use

An electrolyte and cathode technology used in batteries and additive compounds to solve problems such as cycle life degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

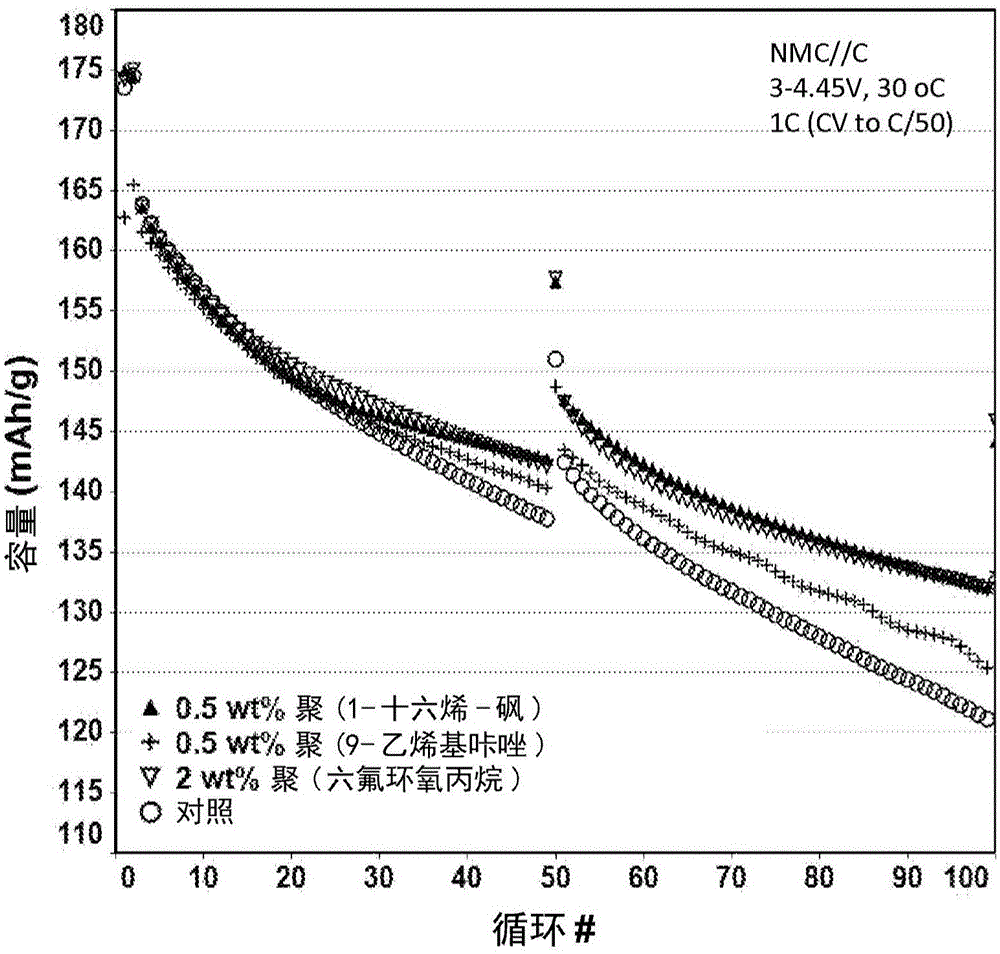

[0077] The battery cells are in a glove box filled with high-purity argon (M-Braun, O 2 And moisture content 0.33 Mn 0.33 Co 0.33 O 2 The cathode material was mixed with poly(vinylidene fluoride) (Sigma Aldrich) and carbon black (SuperPLi, TIMCAL), and 1-methyl-2-pyrrolidone (Sigma Aldrich) was used as a solvent. The prepared slurry is deposited on an aluminum current collector and dried to form a composite anode film. (ii) For the anode, free carbon (G5) was mixed with poly(vinylidene fluoride) (Sigma Aldrich) and carbon black (SuperPLi, TIMCAL), using 1-methyl-2-pyrrolidone (Sigma Aldrich) as a solvent. The prepared slurry is deposited on an aluminum current collector and dried to form a composite cathode film. Each battery cell includes the composite cathode film, a polypropylene separator, and the composite anode film. The common electrolyte is mixed with the given electrolyte additive and added to the battery cell. The battery cell was sealed and cycled between 3V to 4.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com