A pre-twisted wire winding tool and winding method for repairing power transmission wires

A technology for power transmission wires and winding tools, which is applied to equipment for connecting/terminating cables, etc., can solve the problems of short operation time, low process quality, low work efficiency, etc., so as to reduce work intensity, improve process quality, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

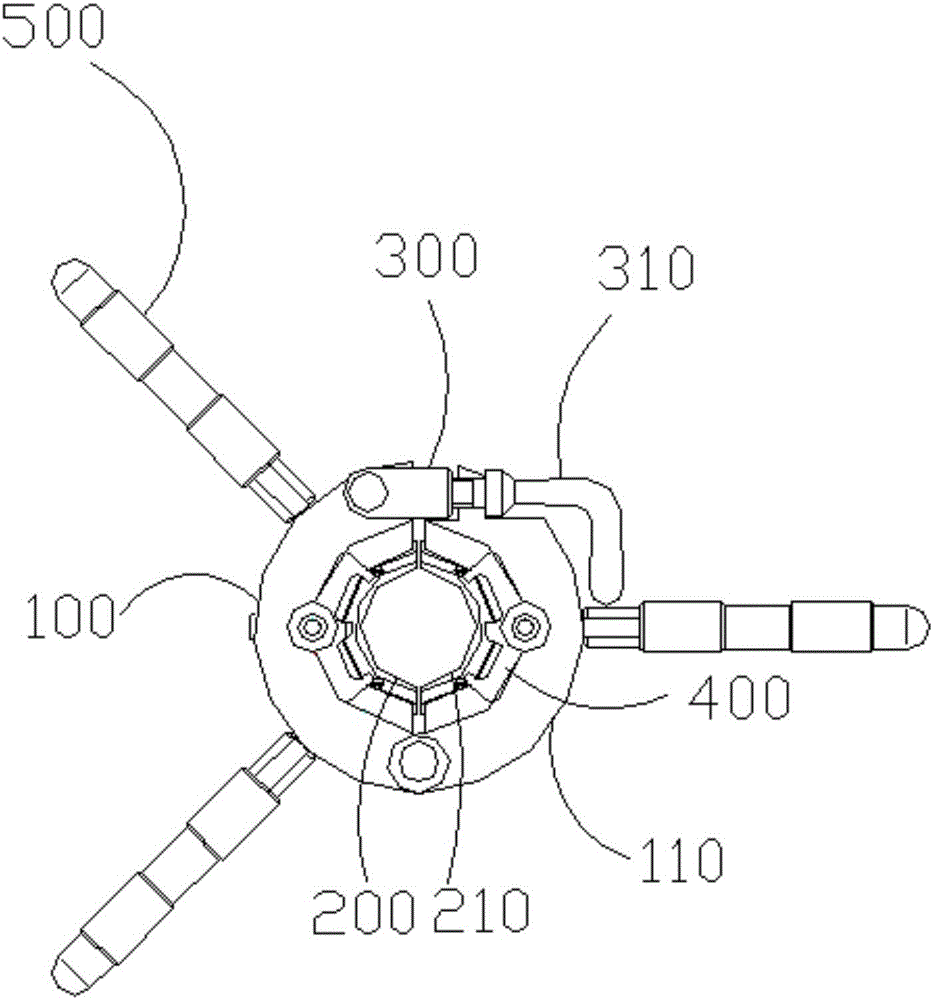

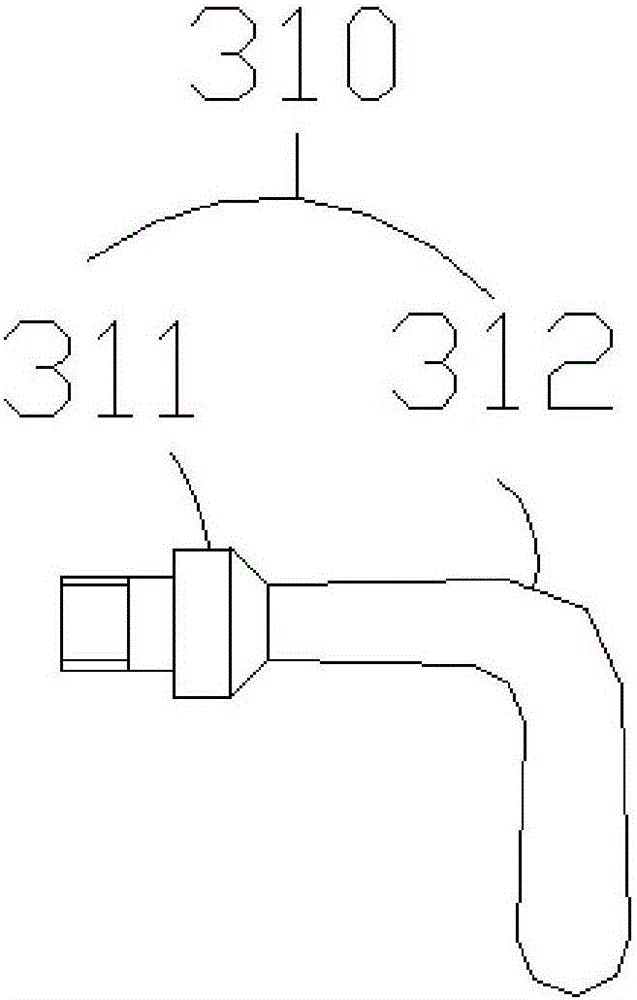

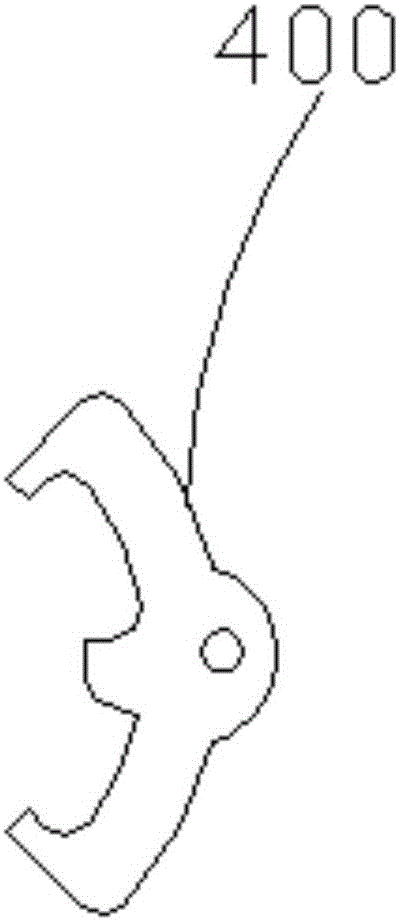

[0035] Such as figure 1 As shown, a pre-twisted wire winding tool for repairing power transmission wires of the present invention includes an outer hafur assembly, an inner hafur assembly that is matched with a groove provided on the inner wall of the outer hafur assembly, and an outer hafur assembly There are three handles 500 evenly distributed on the outer wall of the Harfur component; Figure 4 As shown, the outer Hafur assembly is composed of a first semicircular annular body 100 and a second semicircular annular body 110, and one end of the first semicircular annular body 100 is connected to the second semicircular annular body 110 Any one end of the first semicircular annular body 100 is hinged with a rod-end hinge nut 300 at the other end; figure 2 As shown, the rod-end hinge nut 300 is screwed with a rod-end hinge screw 310 with an annular protrusion, and the other end of the second semicircular annular body 110 is provided with a groove that matches the rod-end hin...

Embodiment 2

[0046] Such as Figure 6 As shown, on the basis of the pre-twisting tool in the design of the present invention, the same pre-twisting tool is designed on the left and right sides of the pre-twisting tool, and the pre-twisting tools on both sides are screwed through the outer Hafur assembly On the middle pre-twisting tool, one of them is designed to be left-handed and the other is designed to be right-handed. When in use, install three pre-twisted wire tools on the broken strands of the transmission wire at the same time, and clamp the pre-twisted wires on the three pre-twisted wire tools, and the pre-twisted wire tool at the left end rotates to the left in a left-handed manner. Wind the pre-twisted wire on the left on the broken strand of the transmission wire; the pre-twisted wire tool on the right rotates to the right in a right-handed manner, wind the right pre-twisted wire on the broken strand of the transmission wire, and the middle pre-twisted wire The wire tool is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com