Collimation instrument for lens detection

A collimation and lens technology, applied in the field of testing equipment, can solve problems such as ignoring assembly quality, low yield, and poor product consistency, and achieve the effect of improving equipment use efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

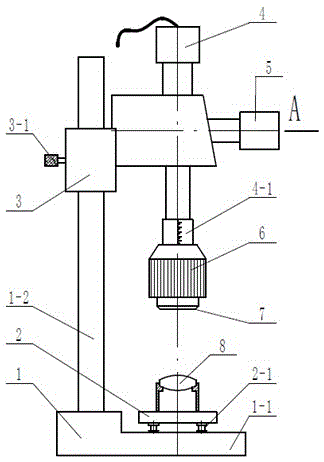

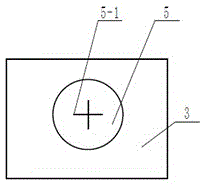

[0012] Depend on figure 1 , figure 2 It is known that a collimator for lens detection is composed of a main bracket 1, a main bracket platform 1-1, a main bracket column 1-2, a storage platform 2, a leg 2-1, a sub bracket 3, and an adjustment knob 3 -1. The light source 4, the scale 4-1, the observation port 5, the cross center line 5-1, the focuser 6, the eyepiece 7, and the lens assembly 8 are composed. The storage platform 2 is fixed on the main support platform 1-1, The auxiliary support 3 is installed on the main support column 1-2, the light source 4 is installed at the upper position of the auxiliary support 3 and penetrates through the auxiliary support 3, the observation port 5 is set at the right end position of the auxiliary support 3 and intersects with the light source 4, and the focus is adjusted. The instrument 6 is installed at the lower end of the light source 4, and the eyepiece 7 is connected with the focusing instrument 6. When working, first adjust the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com