Power meter for micro motor

A dynamometer and micro-motor technology, applied in the field of micro-motor dynamometer, can solve the problems of difficult to measure motor output power, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

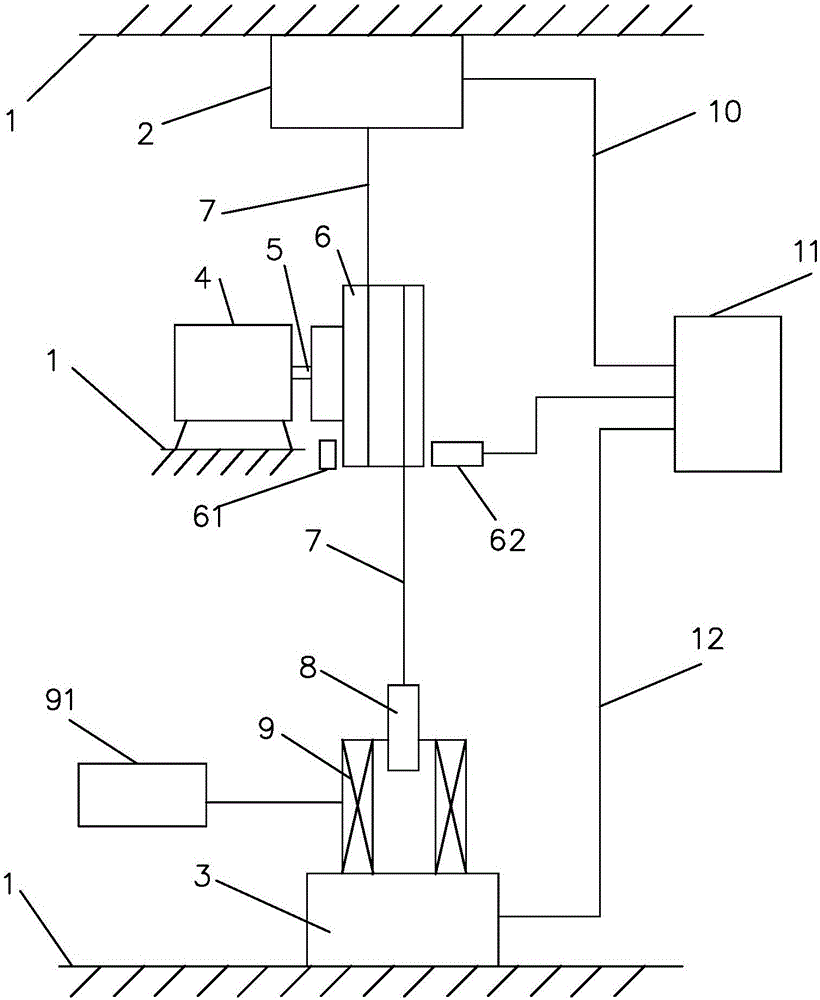

[0023] The structure of the micro-motor dynamometer in the embodiment of the present invention is as follows: figure 1 shown, including:

[0024] - The frame 1 for fixing the motor under test 4, and the motor under test 4 is supported on the mounting platform in the middle of the frame 1;

[0025] - the pulley 6 fixed directly on the shaft end 5 of the motor under test 4 and the wire rope 7 bypassing the pulley 6;

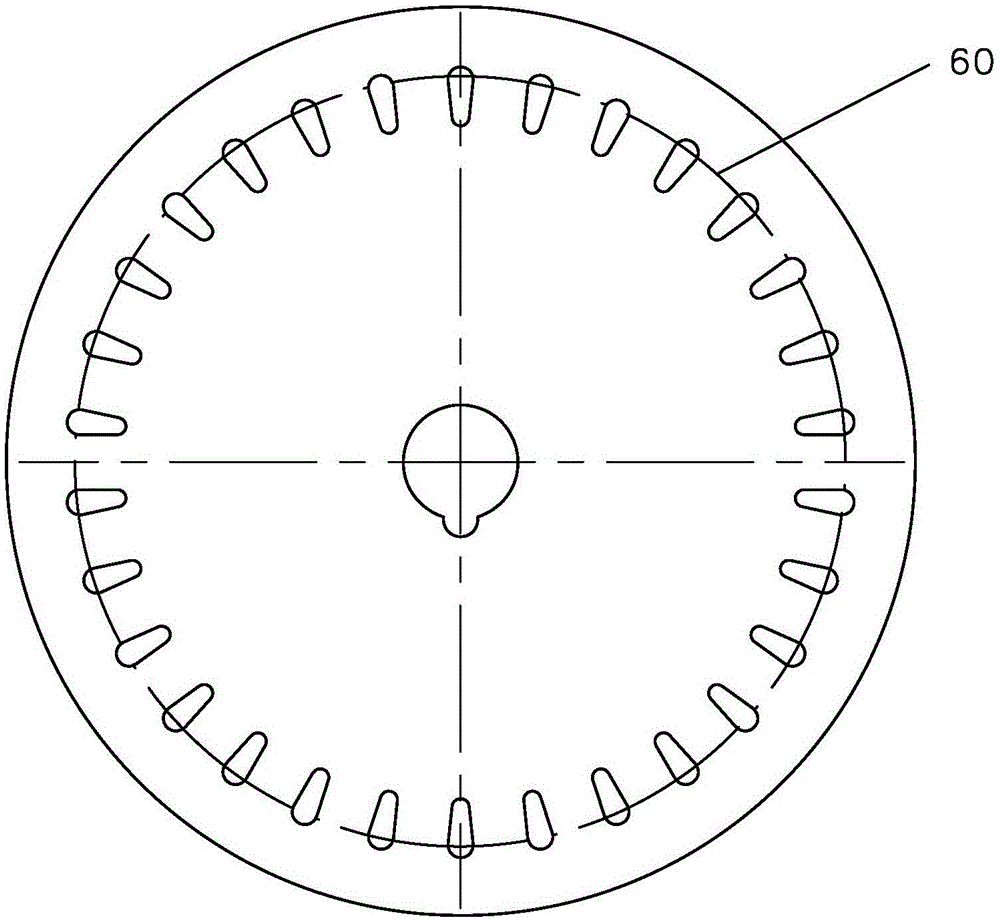

[0026] - pulley 6 as figure 2 As shown, 30 axial through holes of the same size are evenly distributed along the circumference 60 coaxial with it. The light-emitting component 61 and the light-receiving component 62 of the double-molded or shell-inserted photointerrupter are respectively located on the left and right sides of the circumference 60. right two sides;

[0027] ——The shell is fixed on the tension sensor 2 on the top of the frame 1, the force sensing direction is vertically downward, and the upper end of the rope 7 is fixed on the sensing end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com