Pentagonal velocity-averaging tube

An even velocity tube and pentagon technology, which is applied in the field of equal velocity tube flowmeters, can solve the problems of irregular pressure changes in the wake region, unstable flow coefficients of the equal velocity tubes, and difficulty in grasping the change law, etc. The coefficient is stable, the manufacturing cost is low, and the production and processing difficulty is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing

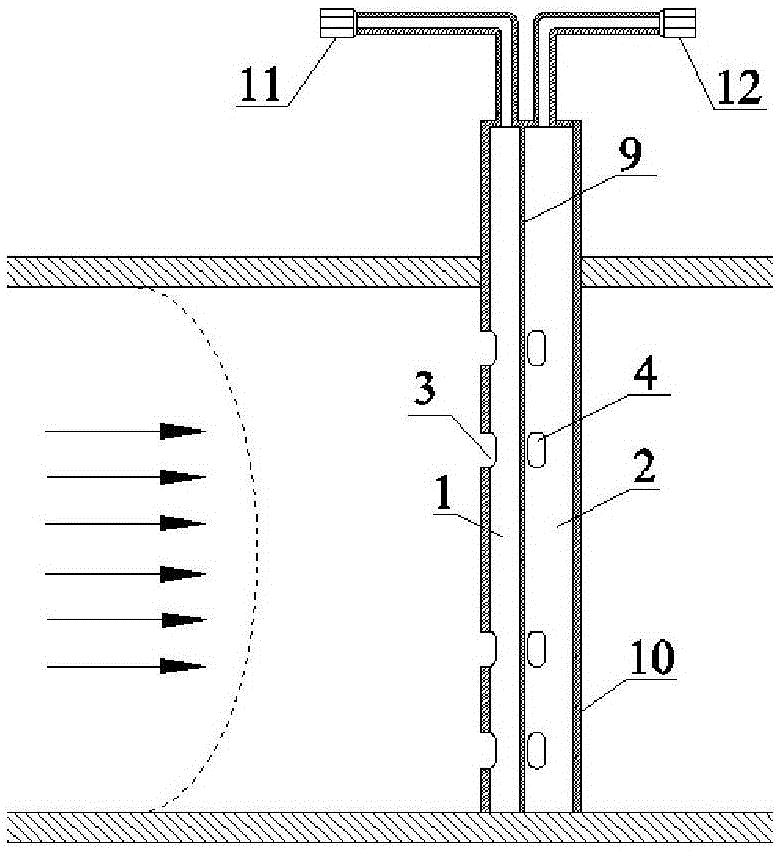

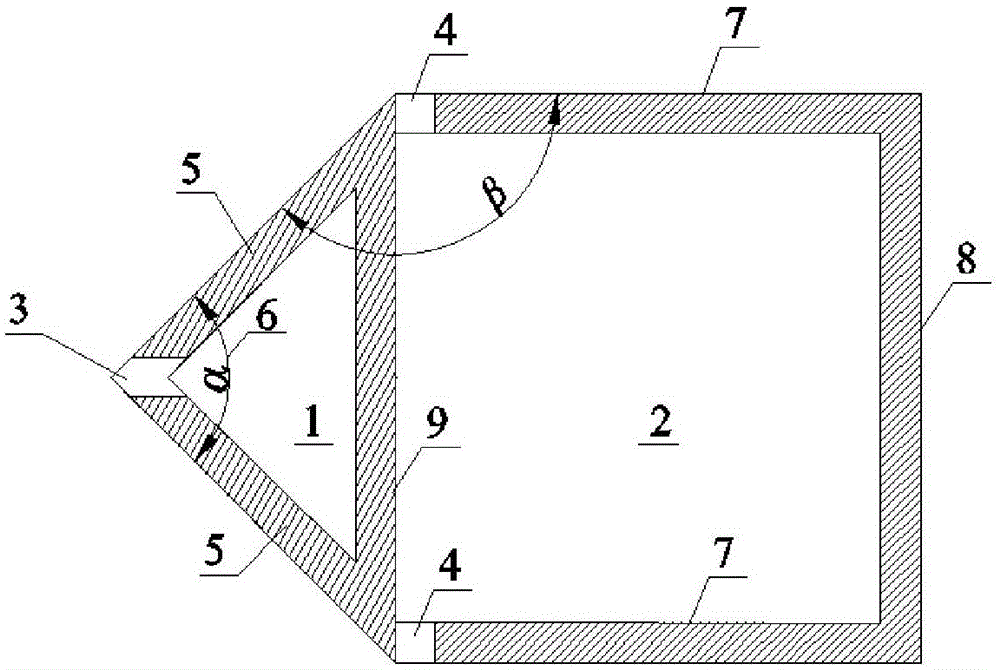

[0021] A detection rod 10 of a pentagonal speed-averaging tube. The inside of the detection rod is divided into two parts, a high-pressure chamber 1 and a low-pressure chamber 2, by a partition 9. The high-pressure chamber 1 transmits the pressure to the high-pressure end interface 11 of the secondary instrument, and the low-pressure chamber 2 transmits the pressure to the low-pressure end interface 12 of the secondary instrument; the cross-sectional shape of the velocity-averaging tube detection rod 10 is along the fluid flow direction Axisymmetric pentagon, the angle between the two upstream sides 5 constitutes the upstream angle 6, and the two upstream sides 5 and the partition 9 form a high-pressure chamber 1 with a triangular cross-section; the downstream sides 7 on both sides It forms a quadrilateral low-pressure chamber 2 with the backflow bottom edge 8 of the pentago...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com