Drilling fluid circulation manifold drilling base pipe clip and installation method thereof

A drilling fluid circulation and drilling rig base technology, applied in the direction of pipes/pipe joints/fittings, pipe supports, mechanical equipment, etc., can solve the problems of damaged drilling fluid circulation manifolds, limited strength of fixed pipe clamps, and non-adjustable height, etc., to achieve Reduced production cost, simple structure, and adjustable installation height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

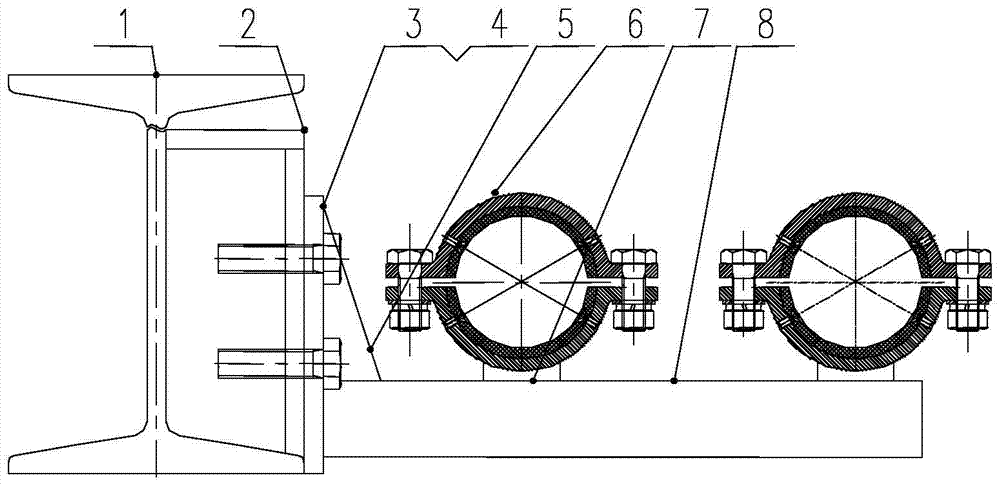

[0024] Attached below figure 1 The structure of the drilling base pipe clip of the drilling fluid circulation manifold described in the present invention is described in detail.

[0025] A drilling fluid circulation manifold drilling base pipe clamp, said drilling fluid circulation manifold drilling rig base pipe clamp includes a support plate 2, an adjustable vertical plate 3, bolts 4, a reinforcement plate 5, a pipe clamp 6 and a support 7; The support plate 2 is welded on the I-beam 1 of the drilling rig base; the adjustable vertical plate 3 is connected with the support plate 2 through the bolt 4; the support 7 is welded on the adjustable vertical plate 3; The reinforcing plate 5 connects the adjustable vertical plate 3 and the support 7 to increase the connection strength between the two, and the tube clip 6 is arranged on the support 7 . The pipe clip 6 is sequentially provided with a guard plate and an elastic backing plate along the radial direction, and the guard pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com