A spring air pressure damping shock absorber

A shock absorber and air pressure technology, which is applied in the direction of spring/shock absorber, shock absorber, gas shock absorber, etc., can solve the problems of poor air pressure damping resilience and soft shock absorber, so as to increase the load and realize Soft and hard balance, moderate rebound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

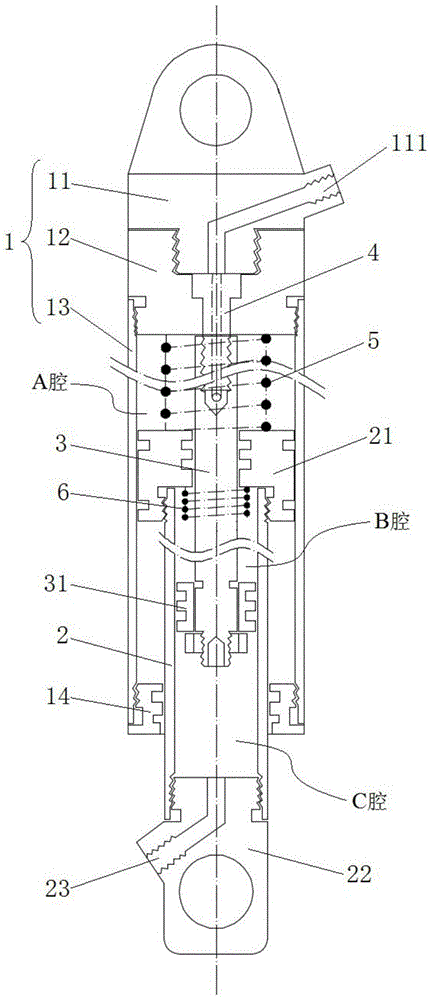

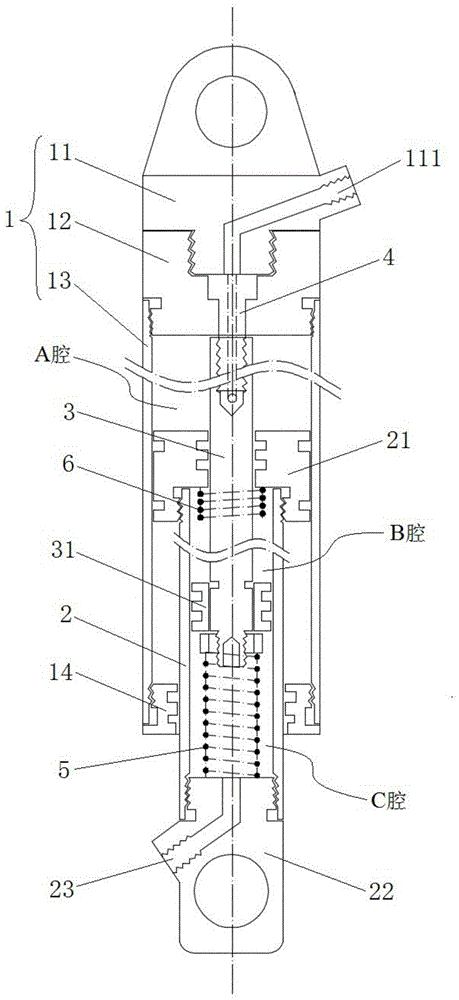

[0030] combine figure 1 and figure 2 As shown, a spring air pressure damping shock absorber of this embodiment mainly includes an outer tube 1, an inner tube 2 and a piston rod 3, the inner tube 2 is arranged inside the outer tube 1, one end is located inside the outer tube 1, and the other end Located outside the outer tube 1, and the end of the inner tube 2 located inside the outer tube 1 is provided with an inner tube piston 21, which cooperates with the inner wall of the outer tube 1 to form a sealed cavity A; one end of the piston rod 3 is fixed on the The end of the outer tube 1, the other end passes through the inner tube piston 21 and extends into the sealed inner tube 2, and at this end is provided with a damping piston 31 that matches the inner wall of the inner tube 2, and the damping piston 31 separates the inner tube 2 It is a sealed chamber B and C chamber, wherein, chamber B is a chamber with a rod, chamber C is a chamber without a rod; chamber A, chamber B an...

Embodiment 2

[0034] The basic structure of a spring air pressure damping shock absorber of this embodiment is the same as that of Embodiment 1, the difference is that: the damping piston 31 in this embodiment is also provided with air pressure damping holes, and the damping of the damping piston 31 by the gas medium is used. The damping effect in the hole greatly improves the damping force of the gas medium, making the air pressure damping effect more stable. The structure of the above-mentioned damping piston 31 and the Chinese patent number: ZL201520070094.X, the authorized announcement date is: July 1, 2015, and the name of the invention is: a pneumatic damping mechanism and a pneumatic damping shock absorber using the mechanism, published in The structure and principle of the damping piston are the same, and will not be repeated here.

Embodiment 3

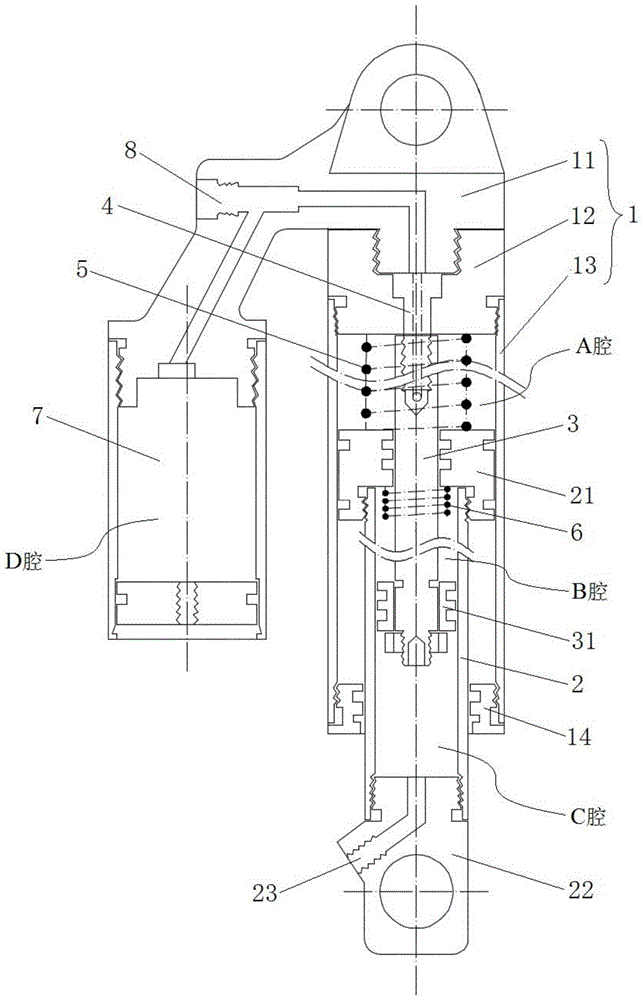

[0036] combine image 3 and Figure 4 As shown, the basic structure of a kind of spring air pressure damping shock absorber of the present embodiment is the same as that of Embodiment 1, the difference is that: the outer tube 1 of the present embodiment is provided with a pressure bottle 7 communicating with the A cavity, and the outer tube 1 includes The upper shaft base 11, the connecting piece 12 and the hollow sleeve 13, the upper shaft base 11 is connected with the hollow sleeve 13 through the connecting piece 12, the piston rod 3 is fixedly installed on the connecting piece 12 by the lifting screw 4, and the lifting screw 4 A vent hole is provided, and the air pressure bottle 7 is arranged on the side wall of the upper shaft seat 11, and the air pressure bottle 7 communicates with the A cavity through the above-mentioned vent hole; The damping adjustment rod 8 and the air pressure bottle 7 are equivalent to the D cavity, and the air pressure bottle 7 can automatically r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com