Method for improving wind power utilization of vertical axis wind turbine blade by using guide strip technology

A technology of wind turbine blades and guide strips is applied to wind turbines, wind turbines, motors and other directions at right angles to the wind direction. The effect of increasing the tangential force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

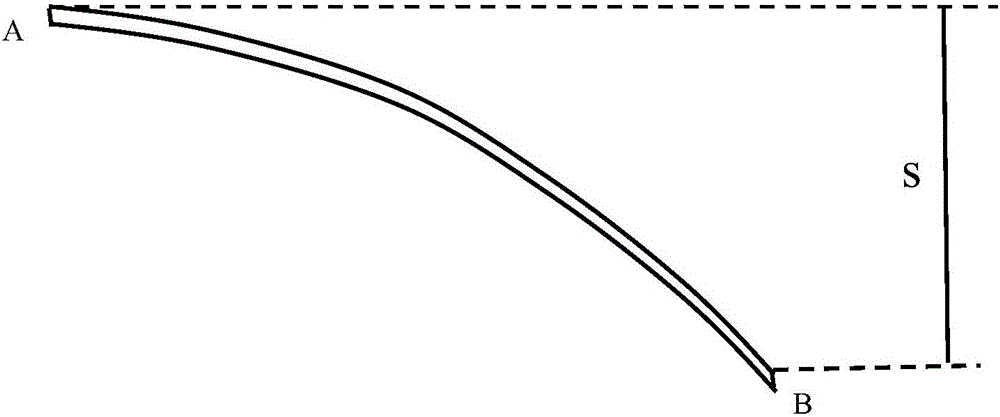

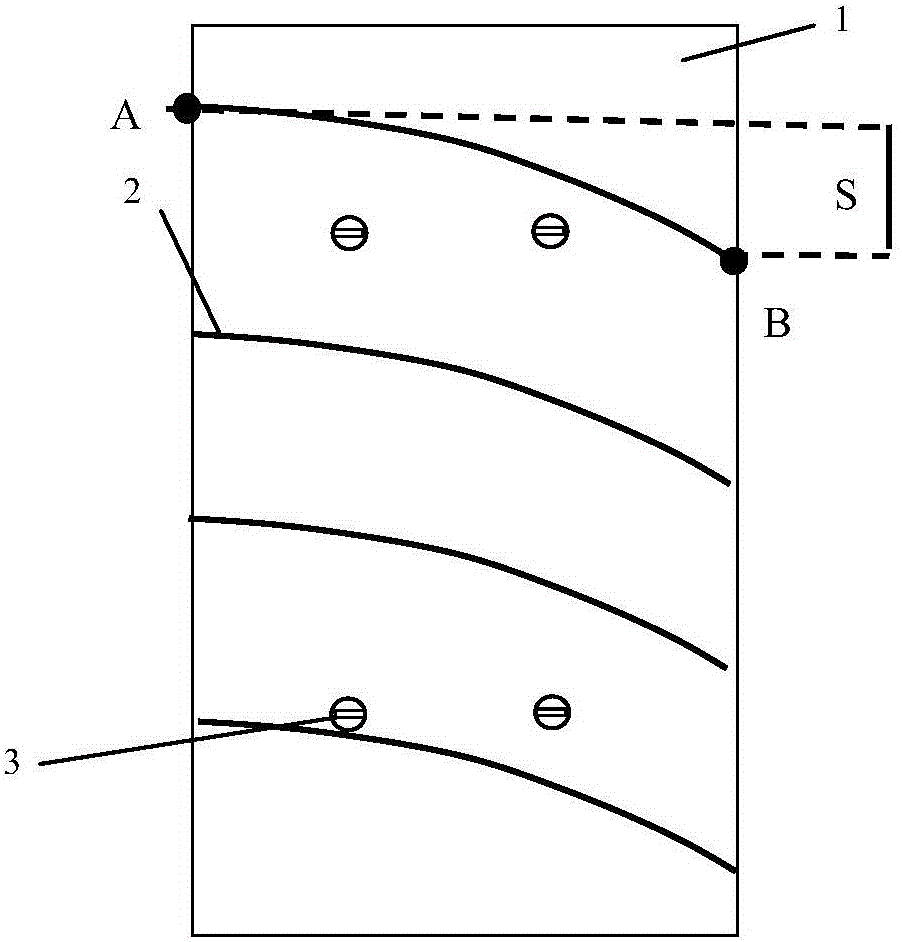

[0015] Such as Figure 1-Figure 4 Shown: The vertical axis wind turbine blade uses the guide strip technology to improve the utilization of wind energy. On the vertical axis wind turbine blade 1, a guide strip is installed along the span direction of the blade 1 at 20%, 40%, 60%, and 80%. 2. The symmetrical airfoil 0018 is selected as the experimental airfoil with a chord length of 100mm. Blade 1 adopts wooden to make, for preventing that blade 1 rotation intensity is not enough. Embedded metal steel components are designed inside the blade 1, 3 pieces are embedded in each blade, and the steel parts of each blade are in the same position to avoid unbalanced rotation of the fan. The blade 1 plus the guide bar 2 ensures that the original aerodynamic shape of the airfoil will not be changed. The height of the diversion strip 2 is 3mm, the thickness is 1mm, and the offset distance S is 6mm. The diversion strip 2 is pasted on the blade 1 in any arc transition from point A to poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com