High-pressure gas seam-expanding, grouting and water-plugging method for precutting trough of microfissure surrounding rock

A technology of high-pressure gas and micro-cracks, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve problems such as difficult to accurately control the penetration of cracks and poor water blocking effect, achieve high direct application value on site, improve injection Slurry water blocking effect, simple effect of on-site operation and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

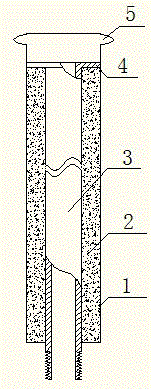

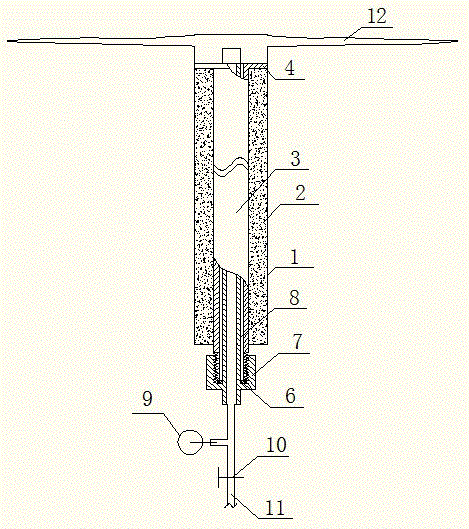

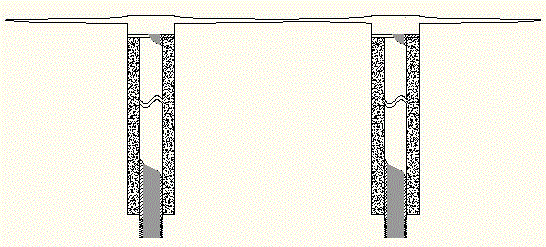

[0019] like Figure 1~Figure 3 As shown, the technical solution of the present invention is mainly divided into three steps for implementation. First, the grouting hole grooving treatment and the installation of the grouting sleeve are carried out; secondly, high-pressure gas is used to artificially expand the surrounding rock; finally, the cracks of the surrounding rock are injected. Slurry plugging, the detailed steps are as follows:

[0020] The first step is to drill the grouting hole 1 in the micro-crack sweat seepage area of the surrounding rock according to the designed arrangement of the plum blossom-shaped grouting holes, to ensure that the depth of each grouting hole is consistent, and the error is less than 1cm, and then the bottom of the grouting hole Grooving pretreatment is carried out at the same position of the surrounding rock, so that the surrounding rock at the bottom of the grouting hole produces a circumferential cutting groove 5, the grouting casing 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com