A Cellless Steel-Concrete Combined Segment Structure of a Hybrid Beam Bridge

A technology of mixed beams and combined sections, applied in bridges, buildings, etc., can solve problems such as transitional uneven bridge deck pavement, and achieve the effects of improving local stress concentration, convenient construction and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

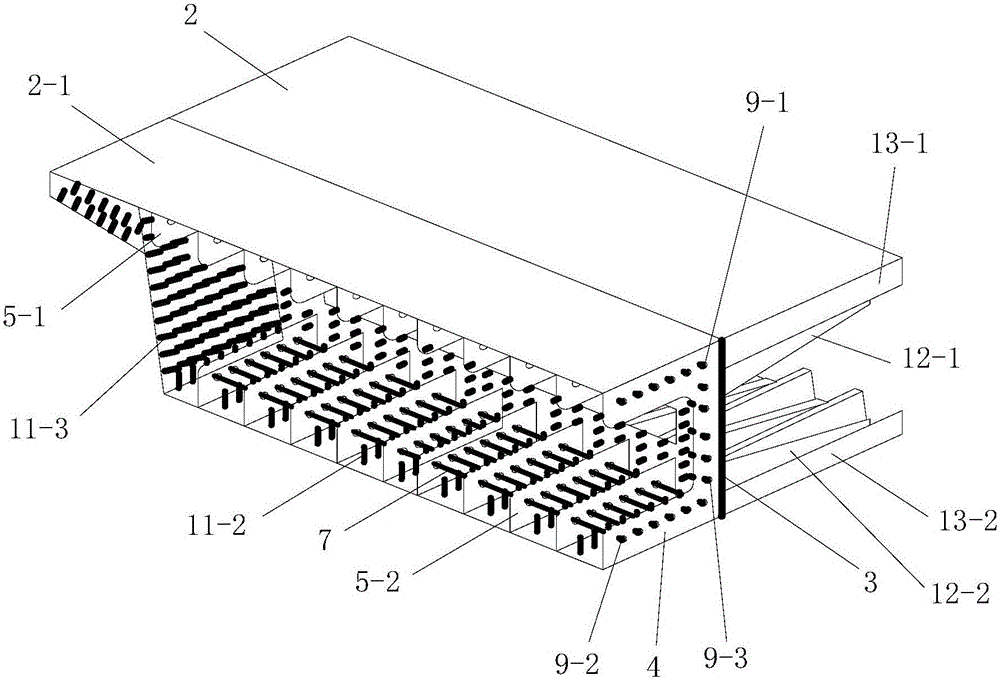

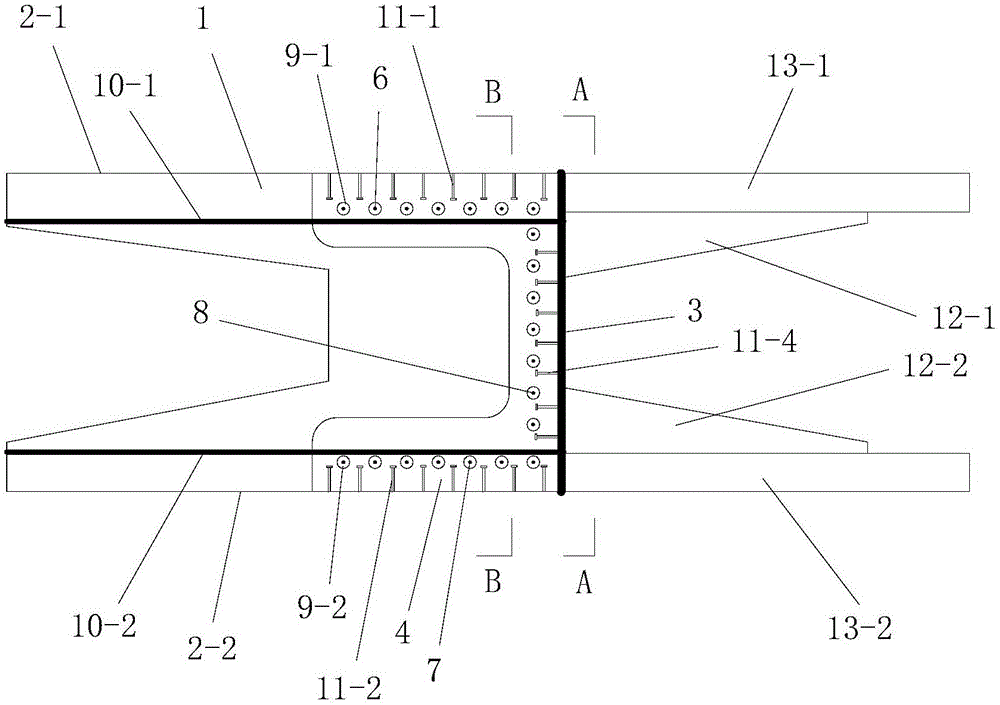

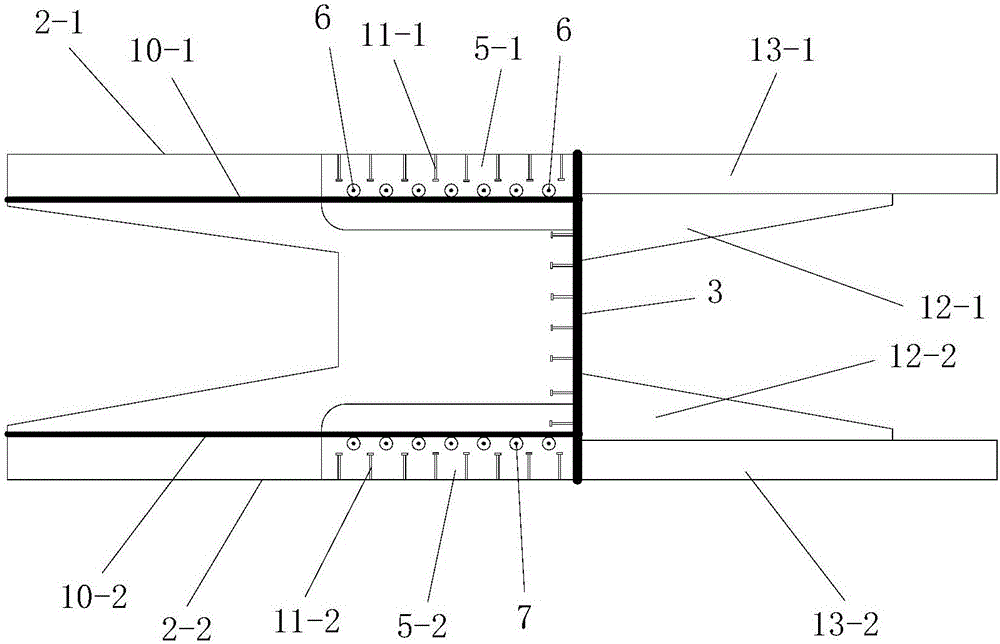

[0045] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention includes a pressure bearing plate 3 located at the rear end of the concrete box girder 1, a front shear connection structure located at the front side of the pressure bearing plate 3, and a rear stiffness transition structure located at the rear side of the pressure bearing plate 3. The concrete Both the box girder 1 and the steel box girder 2 are arranged horizontally, and the pressure bearing plate 3 is a straight steel plate arranged vertically. The pressure bearing plate 3 is located inside the front part of the steel box girder 2, the section at the front of the steel box girder 2 located at the front side of the pressure bearing plate 3 is a steel beam extension, and the rear section of the concrete box girder 1 The section is a concrete beam cladding section clad in the steel beam extension section, and the front shear connection structure is arranged in the conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com