Grinding device and method for profiled full-section of rail weld with five grinding heads

A full-section, grinding head technology, used in tracks, track laying, track maintenance, etc., can solve the problems of unstable manual grinding quality, dust environment hazards, low work efficiency, etc., to improve grinding construction efficiency, light environmental pollution, Improve the effect of grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the object, principle and structure of the present invention more clear, the following will be further elaborated in conjunction with the accompanying drawings and specific embodiments.

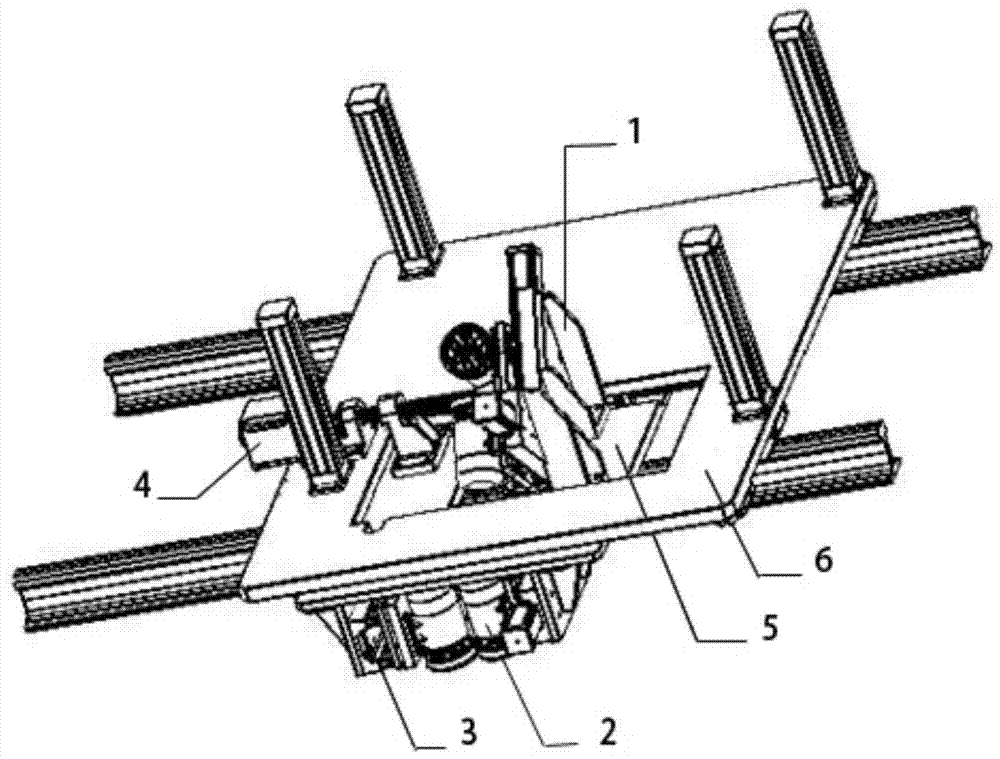

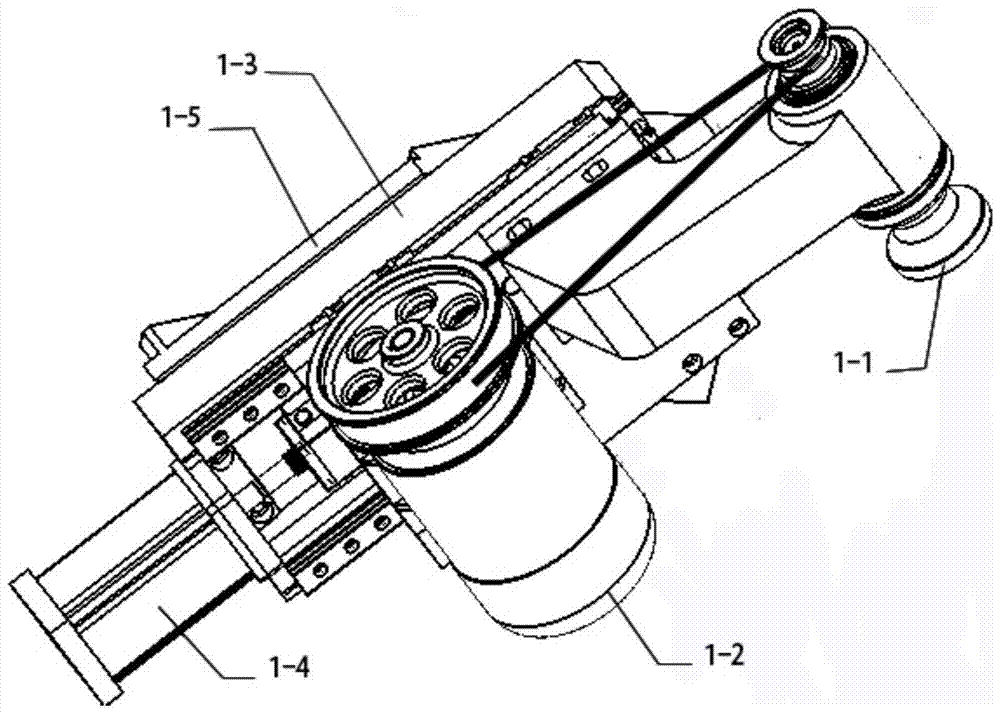

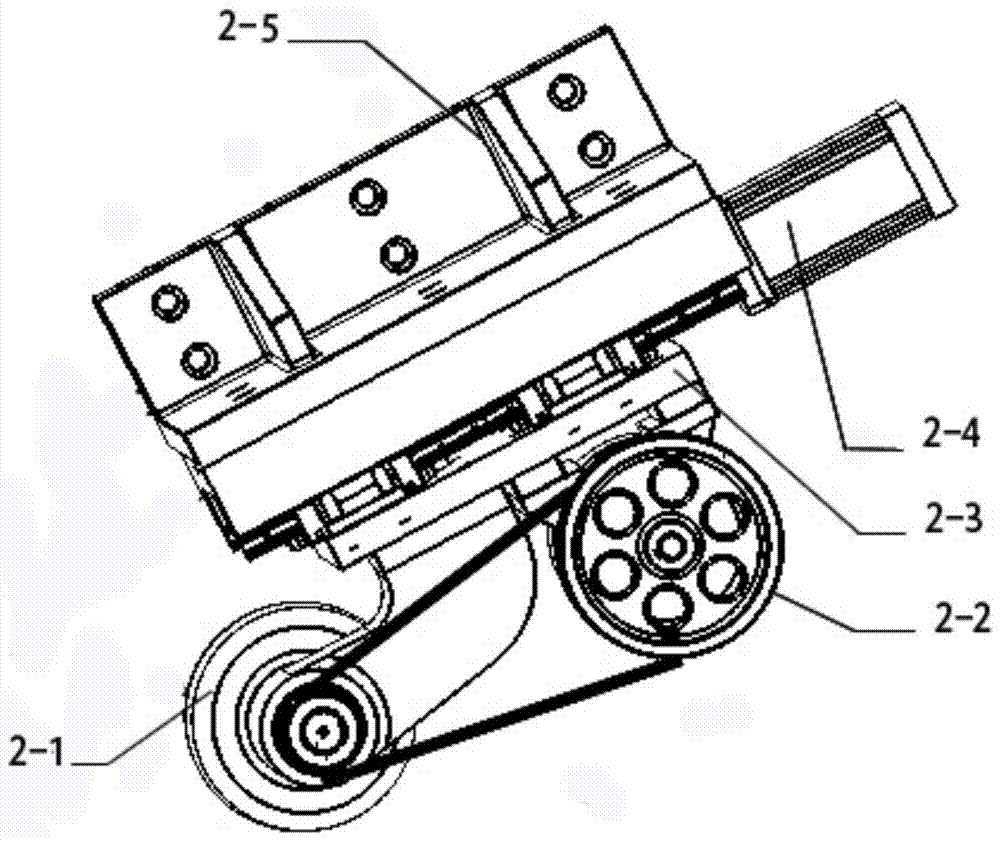

[0047] A five-head profiling full-section grinding machine for rail weld seams, whose structure refers to figure 1 Shown include:

[0048] Grinding the rail weld seam The five-grinding head profiling full-section grinding machine travels to the rail joint weld seam grinding area at the preset position, passes the detection and control given data, and then locates it, and installs it on the foundation sliding table device 5 (installed on the foundation plate assembly 6 Two sets of rail head grinding mechanism 1, two sets of rail waist grinding mechanism 2, and one set of rail bottom grinding mechanism 3 on the line rail 6-5) are driven by the foundation slide table feeding mechanism and are powered to rotate and weld the rail at the same time. The part where the seam e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com