Hot galvanizing system and hot galvanizing method

A technology of hot-dip galvanizing and zinc pot, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems of cumbersome operation, huge mechanical structure, low degree of automation and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

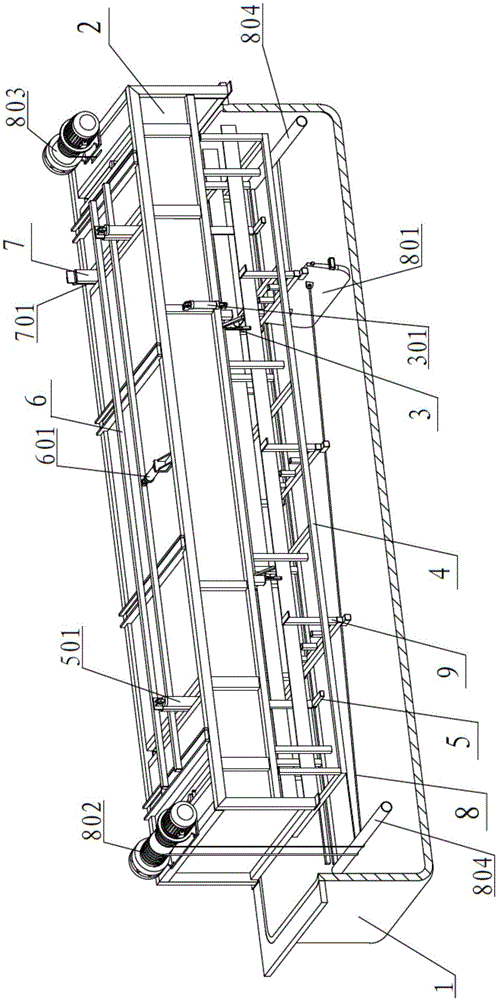

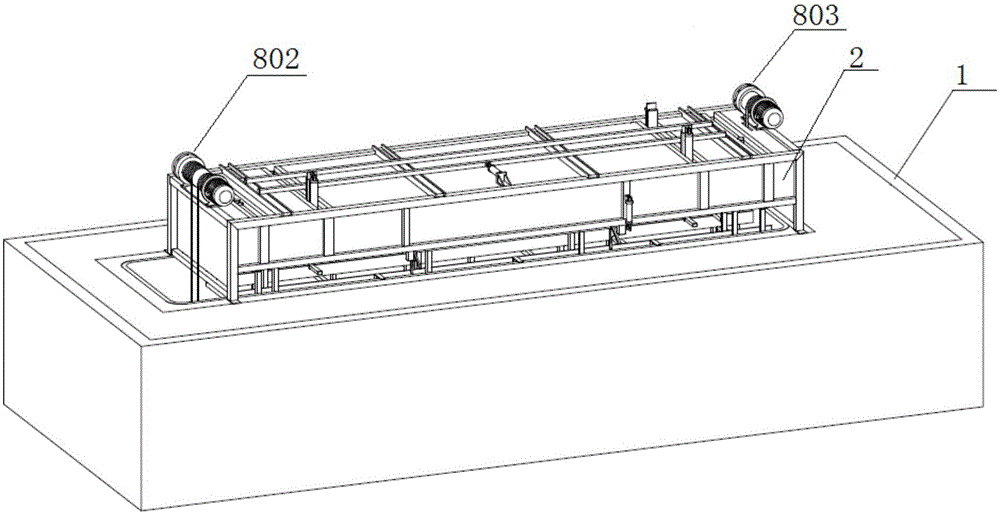

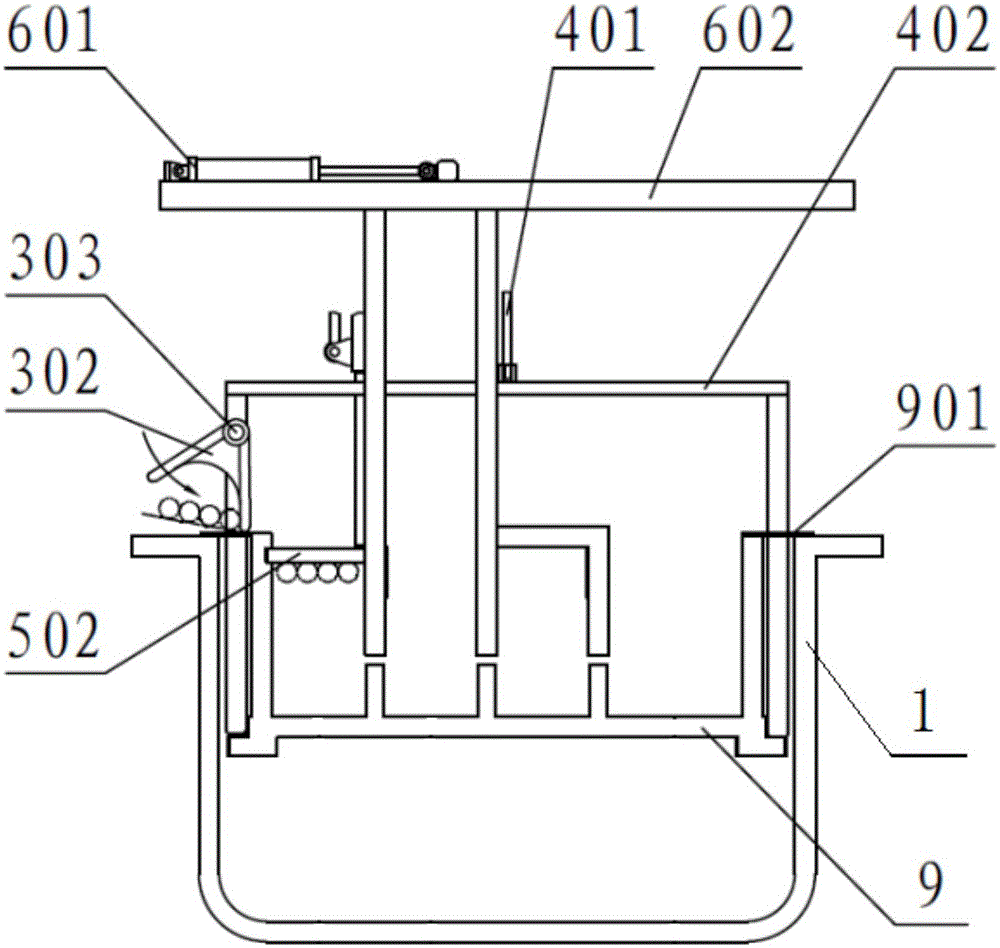

[0045] According to a specific embodiment of the present invention, a hot-dip galvanizing system is provided, the hot-dip galvanizing system includes a zinc pot 1 for containing molten zinc liquid, and the hot-dip galvanizing system includes a feed end and a discharge end , wherein, the zinc pot 1 is provided with a fixed bracket 9, and the fixed bracket 9 divides the interior of the zinc pot 1 into a plurality of stations arranged sequentially from the feed end to the discharge end, and the hot-dip galvanizing system It also includes a lifting device 4 for corresponding to each of the stations and raising and lowering the metal piece, and a pushing device 6 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com