Semitransparent flexible extrusion-blow-molded bottle and preparation method and application thereof

A translucent and soft technology, applied in the field of plastic materials, can solve the problems of high price, high price, poor transparency of LDPE, etc., and achieve the effect of convenient and quick adjustment, low material cost and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Weigh 80 parts of PPRP242G (Basel, Thailand), 10 parts of POEDF710 (Mitsui Chemicals), and 10 parts of LLDPE7042 (Sinopec), respectively, put them in a mixer, and stir for 5 minutes.

[0042] (2) Manually add the mixed materials in step (1) to the blow molding machine (purchased from Hong Kong Yaqi Group Co., Ltd., Yaqi 4+4 (4-die double-station) single-screw blow molding machine, the screw in a hopper with an aspect ratio of 25:1).

[0043] (3) The screw temperature is set to 175°C to 180°C, the die temperature is set to 185°C, and the die temperature is set to 180°C.

[0044] (4) Extrude the blank, adjust the thickness of the blank to be uniform, and set the weight according to the product standard, and finally form a translucent soft squeeze-blowing bottle.

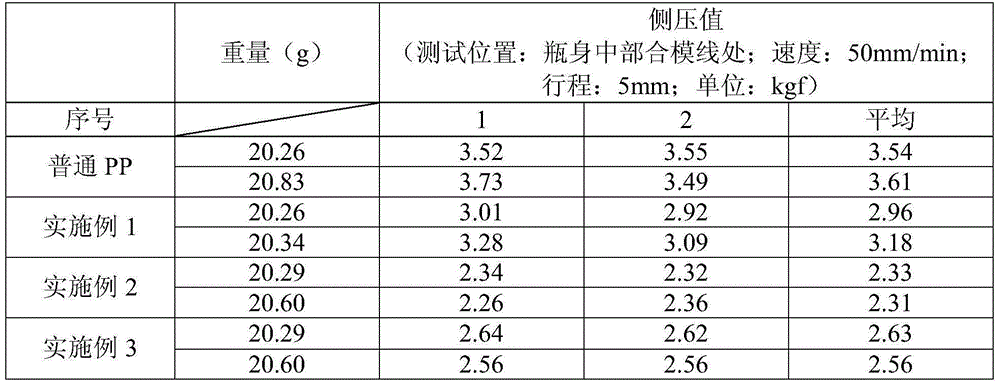

[0045] The light transmittance of the translucent soft squeeze-blown bottle prepared in this example is 55%. The translucent soft squeeze-blow bottle obtained by this embodiment has the characteristics of ...

Embodiment 2

[0047] (1) Weigh 60 parts of PPRP242G, 30 parts of POEDF710, and 10 parts of LLDPE7042, respectively, put them in a mixer, and stir for 5 minutes.

[0048] (2) Manually add the mixed materials in step (1) to the blow molding machine (purchased from Hong Kong Yaqi Group Co., Ltd., Yaqi 4+4 (4-die double-station) single-screw blow molding machine, the screw in a hopper with an aspect ratio of 1:25).

[0049] (3) The screw temperature is set to 175°C to 180°C, the die temperature is set to 185°C, and the die temperature is set to 180°C.

[0050] (4) Extrude the blank, adjust the thickness of the blank to be uniform, and set the weight according to the product standard, and finally form a translucent soft squeeze-blowing bottle.

[0051] The light transmittance of the translucent soft squeeze-blown bottle prepared in this example is 65%. The translucent soft squeeze-blow bottle obtained by this embodiment has the characteristics of easy molding, low cost, and both transparency a...

Embodiment 3

[0054] (1) Add the materials of each component into the corresponding hopper of the automatic batching machine, and set the batching parameters according to 70 parts of PPRP242G, 15 parts of PP-based elastomer SN-0285 (Mitsui Chemicals), and 15 parts of LLDPE7042 , and then start the batching machine, the weighing device of the batching machine is installed and set up to weigh the material, and then the material falls into the mixing hopper. After the mixing hopper is stirred according to the set time, the material falls into the receiving hopper. The automatic batching machine is a weighing batching machine from AEC Company in the United States, model BD-900-5R. Each component material is accurately weighed from the small hopper of the batching machine and dropped into the weighing hopper. It falls into the mixing hopper. After the mixing hopper is evenly mixed by the stirring screw, it finally falls into the receiving hopper.

[0055](2) The mixed material of step (1) is pum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com