Height-adjustable parcel vibration sorting machine

A sorting device and adjustable technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve problems such as slow sorting process, affecting logistics speed, and accumulation of express parcels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

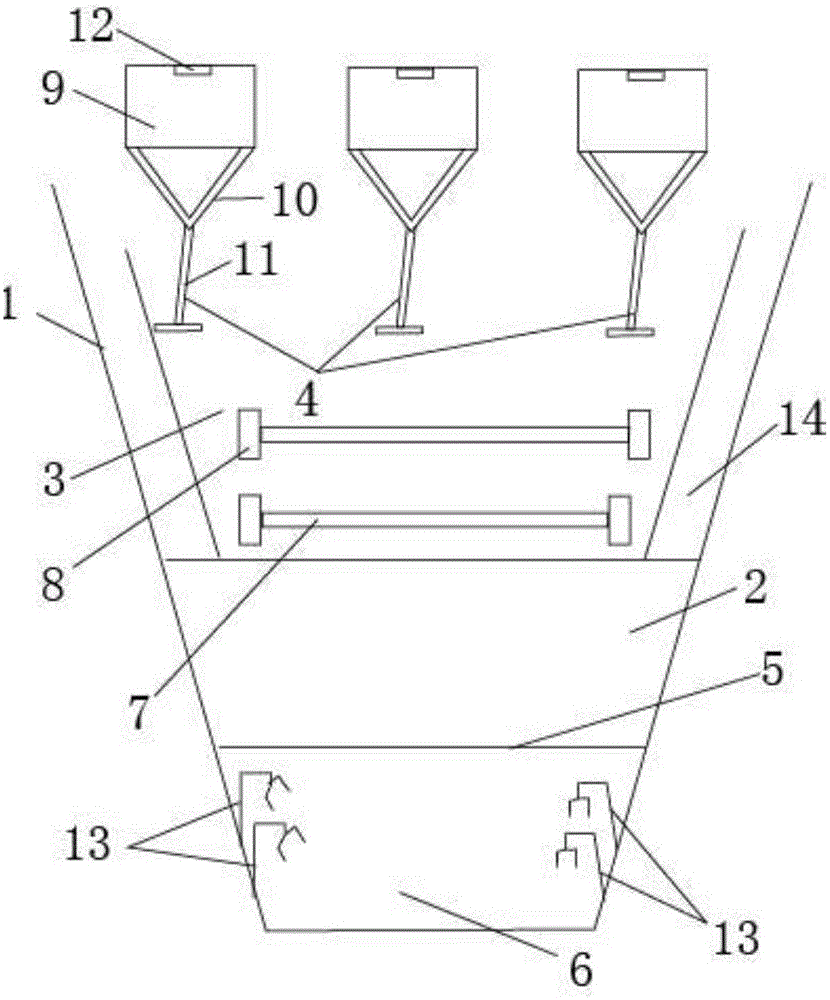

[0030] A height-adjustable package vibration sorting device, which is arranged in sequence with a height-adjustable stacking and pushing device and a vibration sorting device. There are multiple dumping devices above the package conveyor belt, and the vibration sorting device is provided with a package delivery end, which is connected to the manual detection buffer area;

[0031] The package entry end is equipped with an infrared detector, and the infrared detector is connected with the PLC controller;

[0032] The unpacking conveyor belt is provided with a chain unit connected by a plurality of connecting pins on the unpacking conveyor belt, and the chain unit also includes a load beam, a buffer spring is provided on the load beam, and buffer baffles are provided on both sides of the load beam;

[0033] The tipping device includes a tipping bucket body, a tipping bucket balance control lever, a tipping bucket overturning lever, and a driving device. A balance sensor is arrang...

Embodiment 2

[0037] A height-adjustable package vibration sorting device, which is arranged in sequence with a height-adjustable stacking and pushing device and a vibration sorting device. There are multiple dumping devices above the package conveyor belt, and the vibration sorting device is provided with a package delivery end, which is connected to the manual detection buffer area;

[0038] The package entry end is equipped with an infrared detector, and the infrared detector is connected with the PLC controller;

[0039] The unpacking conveyor belt is provided with a chain unit connected by a plurality of connecting pins on the unpacking conveyor belt, and the chain unit also includes a load beam, a buffer spring is provided on the load beam, and buffer baffles are provided on both sides of the load beam;

[0040] The tipping device includes a tipping bucket body, a tipping bucket balance control lever, a tipping bucket overturning lever, and a driving device. A balance sensor is arrang...

Embodiment 3

[0045] A height-adjustable package vibration sorting device, which is arranged in sequence with a height-adjustable stacking and pushing device and a vibration sorting device. There are multiple dumping devices above the package conveyor belt, and the vibration sorting device is provided with a package delivery end, which is connected to the manual detection buffer area;

[0046] The package entry end is equipped with an infrared detector, and the infrared detector is connected with the PLC controller;

[0047] The unpacking conveyor belt is provided with a chain unit connected by a plurality of connecting pins on the unpacking conveyor belt, and the chain unit also includes a load beam, a buffer spring is provided on the load beam, and buffer baffles are provided on both sides of the load beam;

[0048]The tipping device includes a tipping bucket body, a tipping bucket balance control lever, a tipping bucket overturning lever, and a driving device. A balance sensor is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com