Gasket transferring mechanism

A gasket and moving plate technology, which is applied in the direction of conveyors, conveyor objects, vibrating conveyors, etc., can solve the problems that gaskets cannot move in multiple ways, and achieve the effect of multi-directional movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

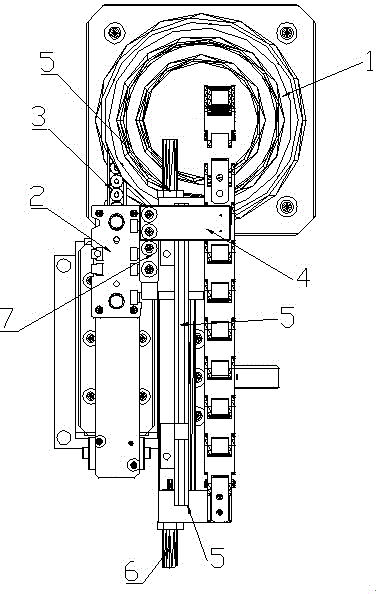

[0014] according to figure 1 , the gasket transplanting mechanism, including the gasket feeding vibrating plate 1, realizes that the gasket moves in the feeding groove through vibration, and it is characterized in that the gasket feeding vibrating disk is connected with the first feeding groove 3 and the second feeding groove 7 at the same time; The first feeding chute is provided with a cover plate 2 for preventing dust; the second feeding chute is covered with a push plate 4, and a movable plate 5 is arranged below the push plate, and the movable plate It is not connected with the second feeding chute.

[0015] The movable plate and the push plate are arranged perpendicular to each other, and the movable plate can be moved until the part of the movable plate is located below the push plate or the entire movable plate is away from the push pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com