An intelligent production line for medical supplies

A technology for medical supplies and production lines, applied in the field of intelligent production lines for medical supplies, can solve the problems of reducing product yield, low production efficiency, fatigue, etc., and achieve the effect of improving production efficiency and reducing defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

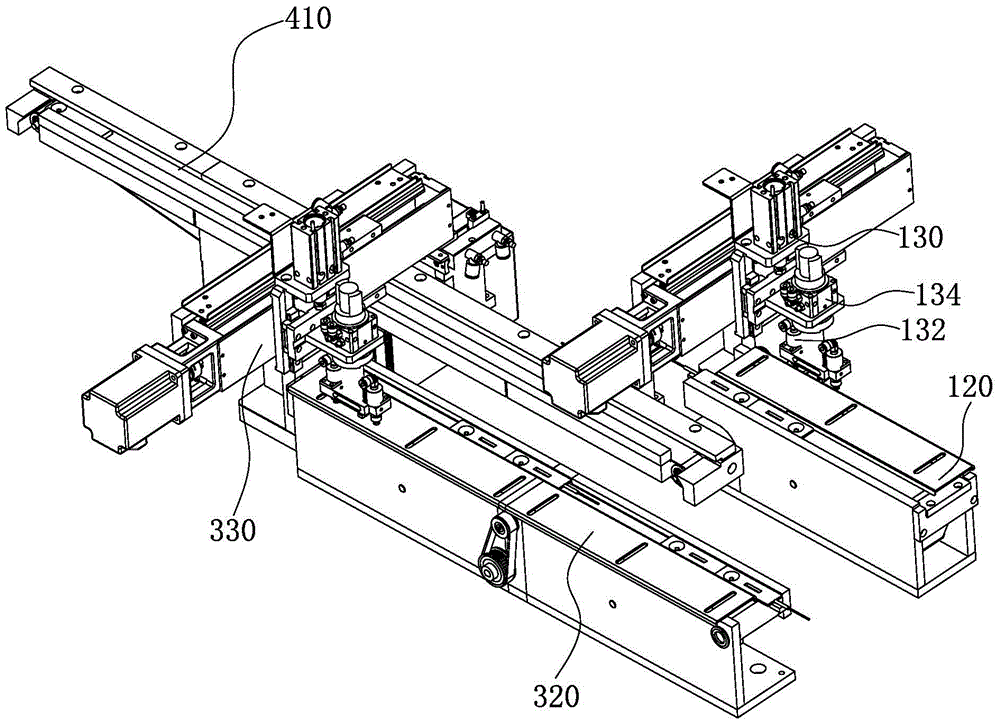

[0037] Pregnancy test stick products mainly include bottom cover, test paper, face cover, desiccant, and packaging bag. The usual production process is to attach the test paper to the bottom cover first, then fasten the face cover to the bottom cover, and then dry The reagent is packaged in a packaging bag together with the assembled bottom cover, test paper, and face cover. The intelligent production line 10 for medical supplies is used for mechanical automation production of pregnancy test stick products to replace traditional manual work methods.

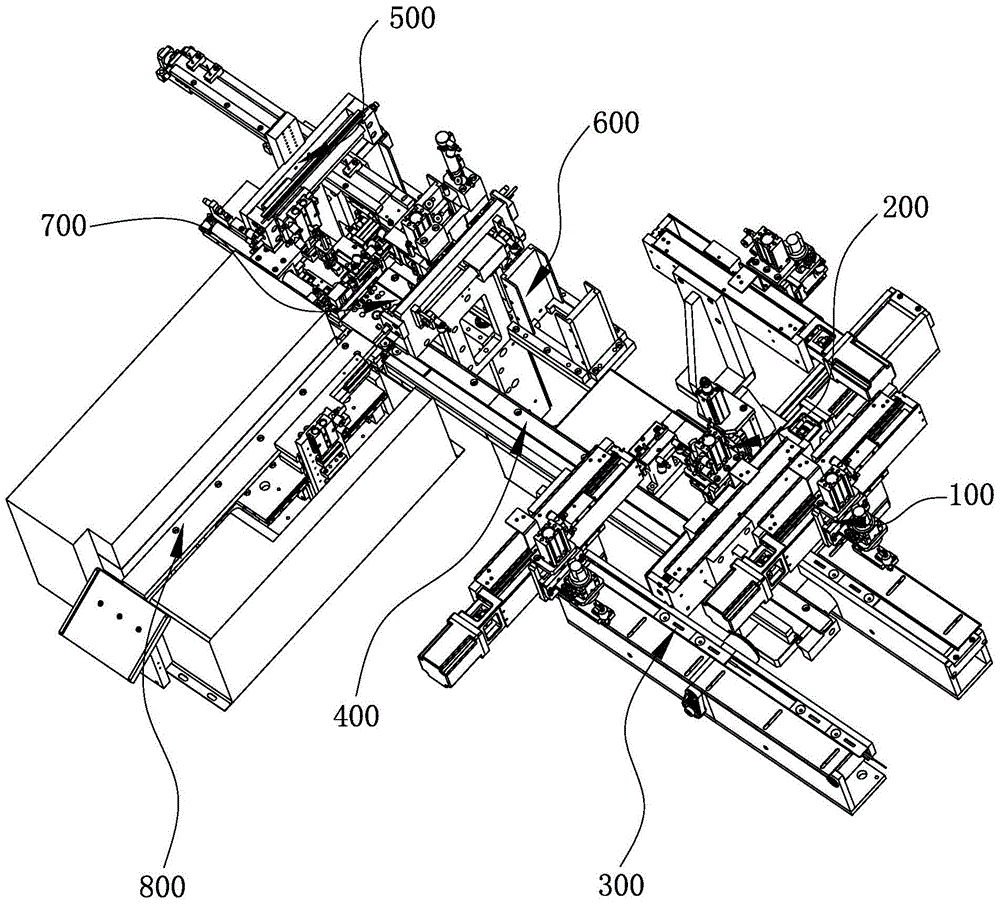

[0038] figure 1 It is an overall structural diagram of an intelligent production line 10 for medical supplies according to an embodiment of the present invention. The intelligent production line 10 for medical supplies in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com