Camouflage product molding method

A molding method and camouflage technology are applied in the field of injection molding equipment and injection molding process of two-color materials, which can solve the problems of inconvenient processing of camouflage shoes, inconvenient handling, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

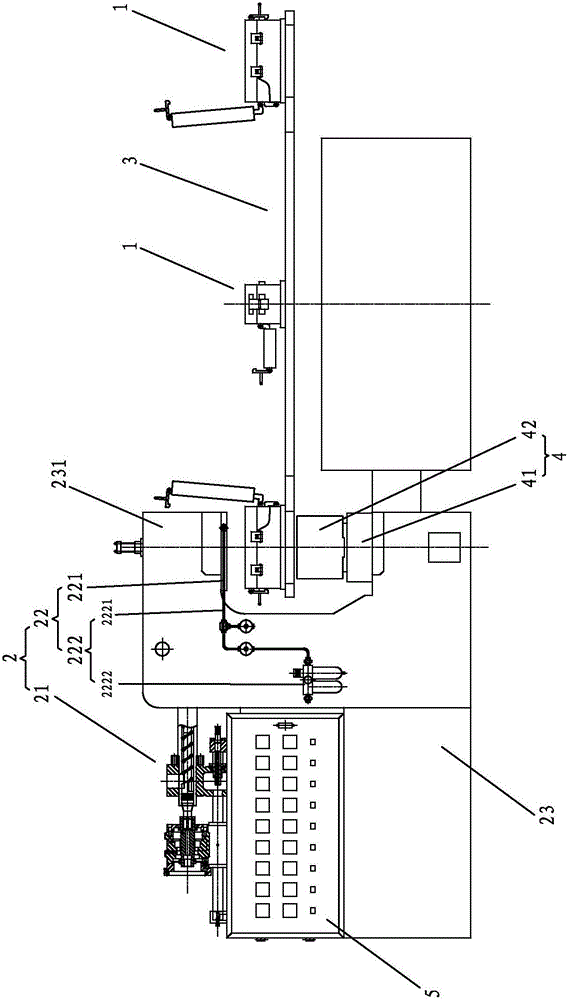

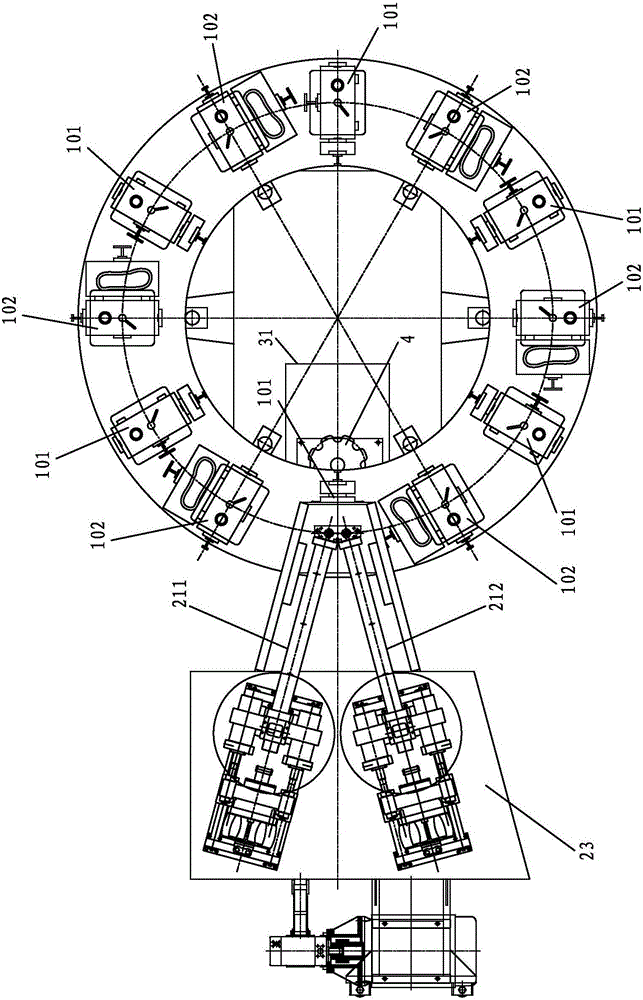

[0048] A kind of injection molding device of the present invention, as Figure 1-10 As shown, it includes a two-color blow mold 1, a material injection hot air blowing device 2, and a conveying device 3 for transporting a plurality of two-color blow molds 1 to perform the injection hot air process one by one.

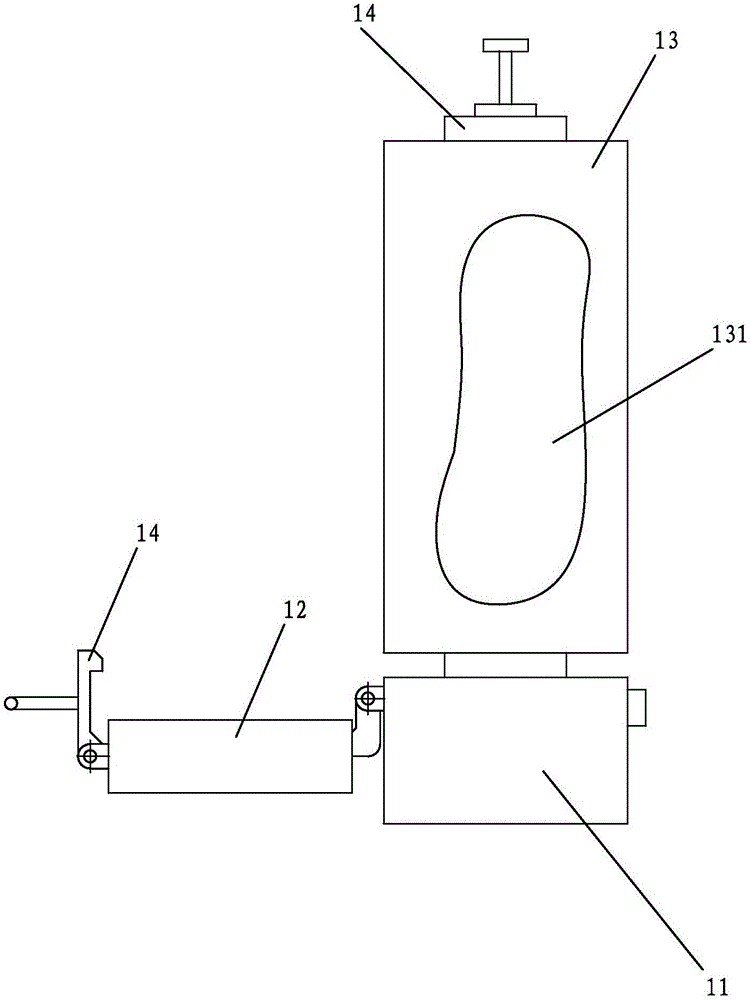

[0049] Injection blowing hot air device 2 includes injection device 21 corresponding to two-color blowing mold 1 injection material, and hot air system 22 corresponding to two-color blowing mold 1 blowing hot air; two-color blowing mold 1 includes mold base 11, forms a small The first mold cover plate 12 of the mold cavity, and the second mold cover plate 13 forming a large mold cavity with the mold base 11; the first mold cover plate 12 has a first color material injection port (not shown in the figure), and the second The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com