Residue removing device for inner wall of window frame

A technology for removing residues in window frames, applied in cleaning methods and appliances, chemical instruments and methods, cleaning methods using gas flow, etc., can solve problems that affect installation, easily hurt installers, and unfavorable environmental sanitation, and achieve efficient cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means and creative features realized by the present invention easy to understand, the present invention will be further elaborated below.

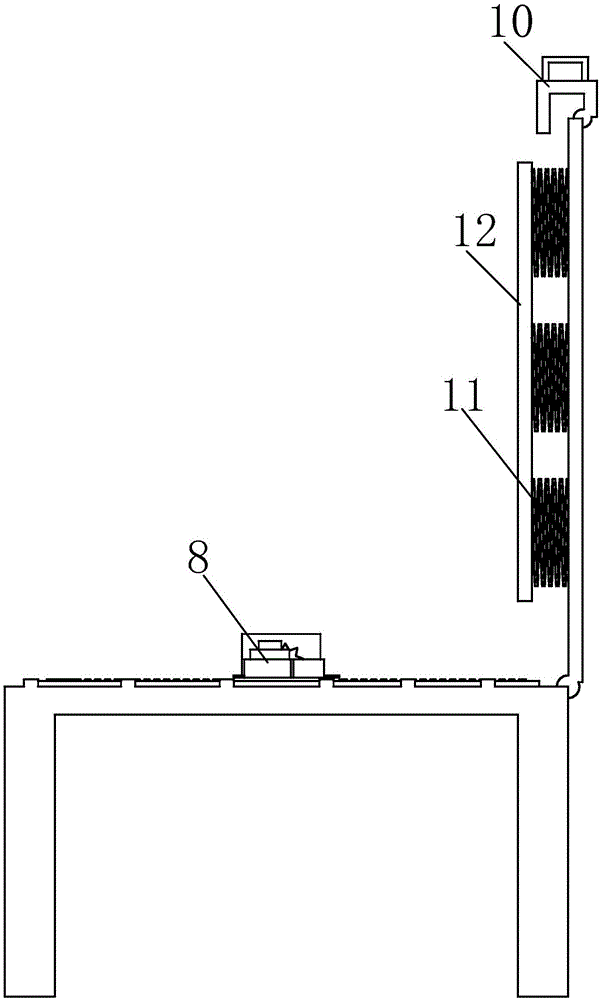

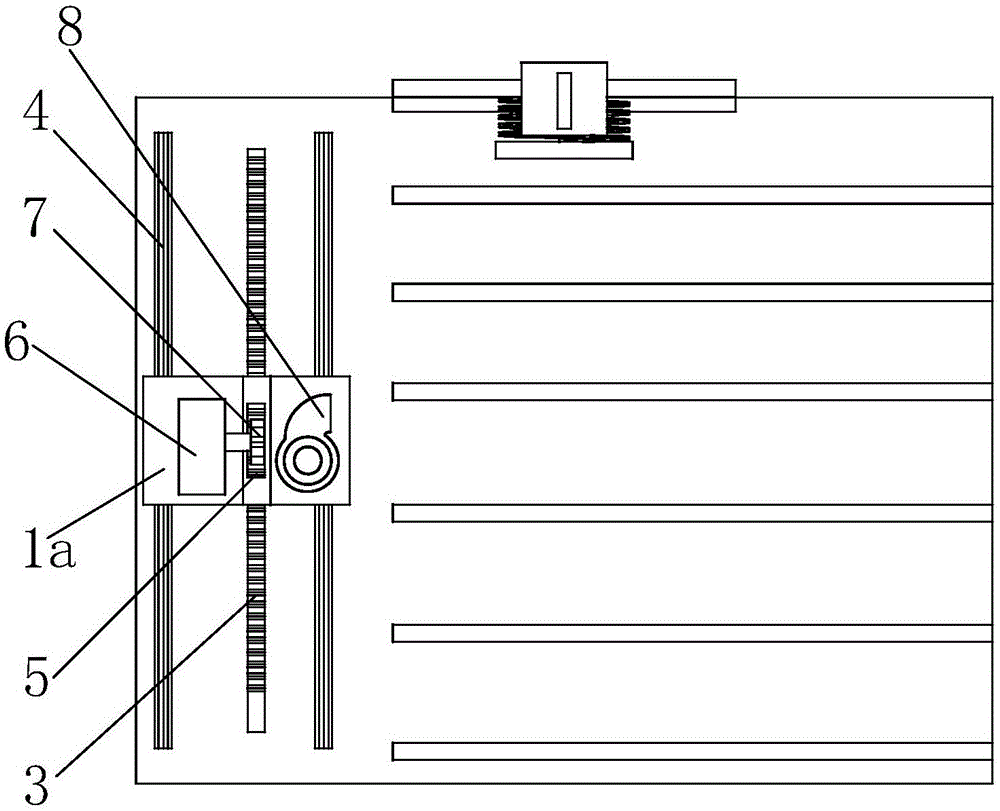

[0017] Such as Figure 1 to Figure 3 As shown, a device for removing debris on the inner wall of a window frame includes a stand 1, a layer of flexible material is attached to the upper end surface of the stand 1, and a number of transversely placed retaining strips 2 are evenly provided on the right part of the upper end surface of the stand 1, The left part of the upper end surface of the stand 1 is provided with a rack 3 placed longitudinally, and a slide rail 4 is provided on the left and right sides of the rack 3 respectively, and the top of the slide rail 4 is jointly set up and is located above the rack 3. The mobile platform 1a of the mobile platform 1a, the middle part of the mobile platform 1a is provided with a rectangular through hole 5 corresponding to the position of the rack 3, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com