Preparation method of spindle-shaped metal organic framework compound grains

A spindle-shaped and granular technology is applied in the field of spindle-shaped metal-organic hybrid particles MIL-88B and its preparation, which can solve the problems that MOFs materials cannot be used in the field of drug carriers, large size cannot be used for bioimaging, and large size of MOFs materials. , to achieve the effect of good photocatalytic degradation performance, excellent light absorption ability and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

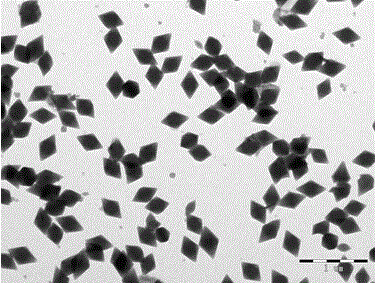

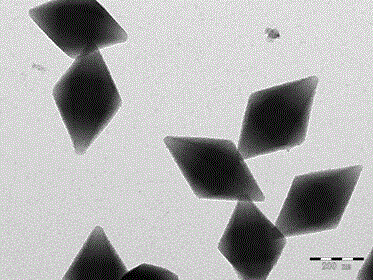

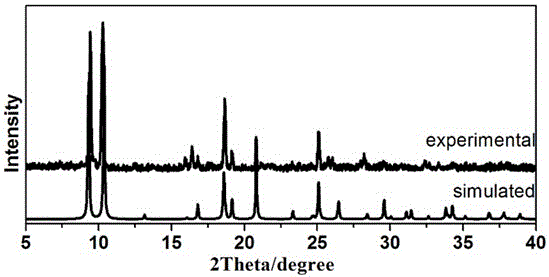

[0026] First take by weighing ferric chloride 0.32mmol and dissolve it in 6 milliliters of DMF and 8 milliliters of acetonitrile, take by weighing 0.36mmol of terephthalic acid and dissolve it in 2 milliliters of DMF, mix the two, and put it into 80 o React in a C oil bath for 1.5 hours, then centrifuge, and use ethanol and deionized water to clean ultrasonically at 60 o Drying at C to obtain MIL-88B(Fe) complex particles.

Embodiment 2

[0028] First take by weighing ferric chloride 0.64mmol and dissolve in 10 milliliters of DMF and 15 milliliters of acetonitrile, take by weighing 0.72mmol of terephthalic acid and dissolve in 5 milliliters of DMF, the two are mixed, and put into 90 o React in a C oil bath for 3 hours, then centrifuge, and use ethanol and deionized water to clean ultrasonically at 60 o Drying at C to obtain MIL-88B(Fe) complex particles.

Embodiment 3

[0030] First take by weighing ferric chloride 0.64mmol and dissolve in 15 milliliters of DMF and 10 milliliters of acetonitrile, take by weighing 0.72mmol of terephthalic acid and dissolve in 5 milliliters of DMF, the two are mixed, and put into 90 o React in a C oil bath for 3 hours, then centrifuge, and use ethanol and deionized water to clean ultrasonically at 60 o Drying at C to obtain MIL-88B(Fe) complex particles with a shape similar to that shown in Figure 1 but with non-uniform sizes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com