A control process for exceeding the demulsification degree of turbine oil in power plant operation

A demulsification degree and demulsification technology, which is applied in the application field of the physical and chemical properties of turbine oil in power plants, can solve the problems of excessive demulsification degree of turbine oil, achieve the effect of prolonging service life and improving demulsification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

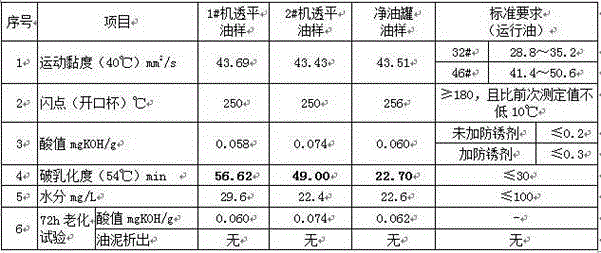

[0030] The degree of demulsification of No. 46 turbine oil in units 1# and 2# of a thermal power plant seriously exceeded the standard, which seriously threatened the safe operation of the unit. The physical and chemical performance indicators remain unchanged;

[0031] (1) Oil evaluation before adding

[0032]

[0033] (2) Selection of resistant demulsifiers

[0034] According to the analysis and identification results of emulsifiers for oil emulsification, the best resistant demulsifier - polyether polymer compound DL32 was selected through experiments, and the additive dosage of turbine oil for 1# machine and 2# machine was 0.014 respectively. %, 0.012%;

[0035] (3) Effect after adding oil

[0036]

example 2

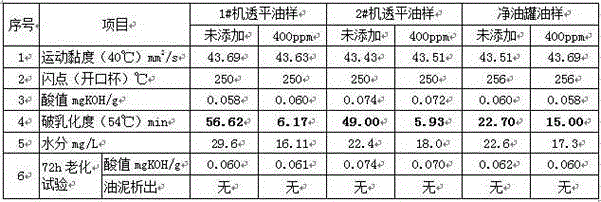

[0038] The degree of demulsification of No. 46 turbine oil in the 1# and 2# units of a hydropower plant and the clean oil tank seriously exceeds the standard, which seriously threatens the safe operation of the unit. After adding a suitable antagonistic demulsifier, the demulsification performance of the turbine oil is remarkable Improvement, other physical and chemical performance indicators remain unchanged;

[0039] (1) Oil evaluation before adding

[0040]

[0041] (2) Selection of resistant demulsifiers

[0042] According to the analysis and identification results of emulsifiers for oil products, the best anti-emulsifier-polyether polymer compound M013 was selected through experiments, and the running turbine oil in 1# machine, 2# machine and net oil tank was added Grade dose is 400ppm;

[0043] (3) Effect after adding oil

[0044]

Description of drawings

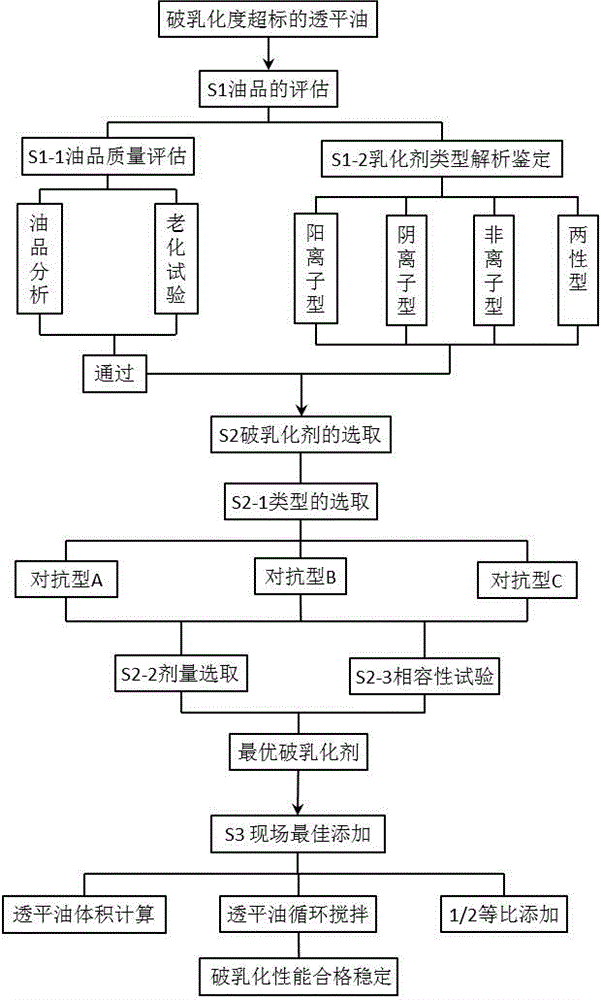

[0045] figure 1 It is the flow chart of the turbine oil demulsification degree exceeding the standard co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com