Composite material for manufacturing small-diameter artificial vascular grafts and manufacturing method for composite material

A composite material and small-caliber technology, applied in the field of artificial blood vessel materials, can solve the problems of poor blood compatibility, high blockage rate, poor compatibility, etc., to improve elasticity and surface properties, reduce blockage rate, good elasticity and surface properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] The composite material used in the preparation of artificial small-diameter blood vessels in this example is composed of C6 carboxylated bacterial cellulose and silk protein, and the silk protein and carboxylated bacterial cellulose are cross-linked and compounded by a cross-linking agent to form the composite material. Specifically, the crosslinking agent used in this example is N-hydroxysuccinimide and carbodiimide. This example adopts self-made C6 carboxylated bacterial cellulose to prepare composite material, therefore, the preparation method of the composite material of this example comprises the following steps:

[0038] (1) C6 carboxylation of bacterial cellulose

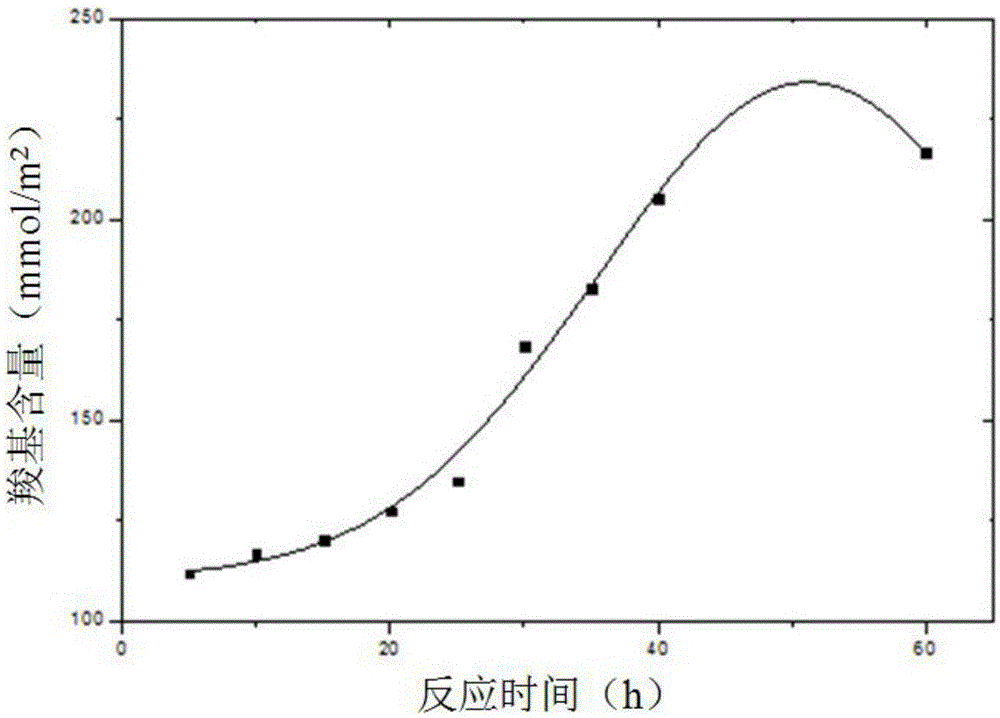

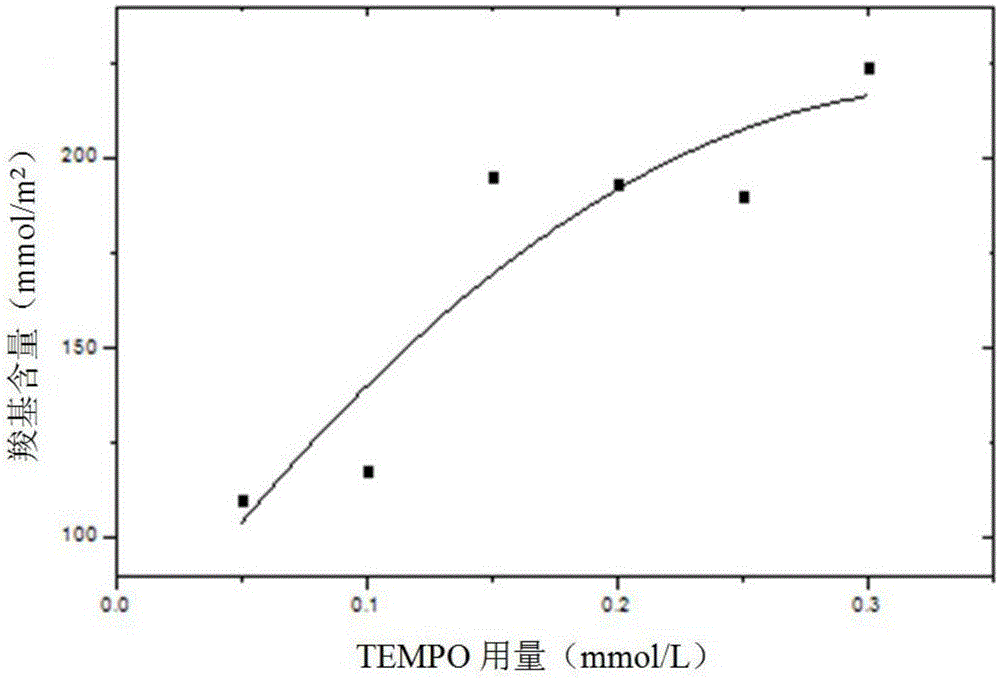

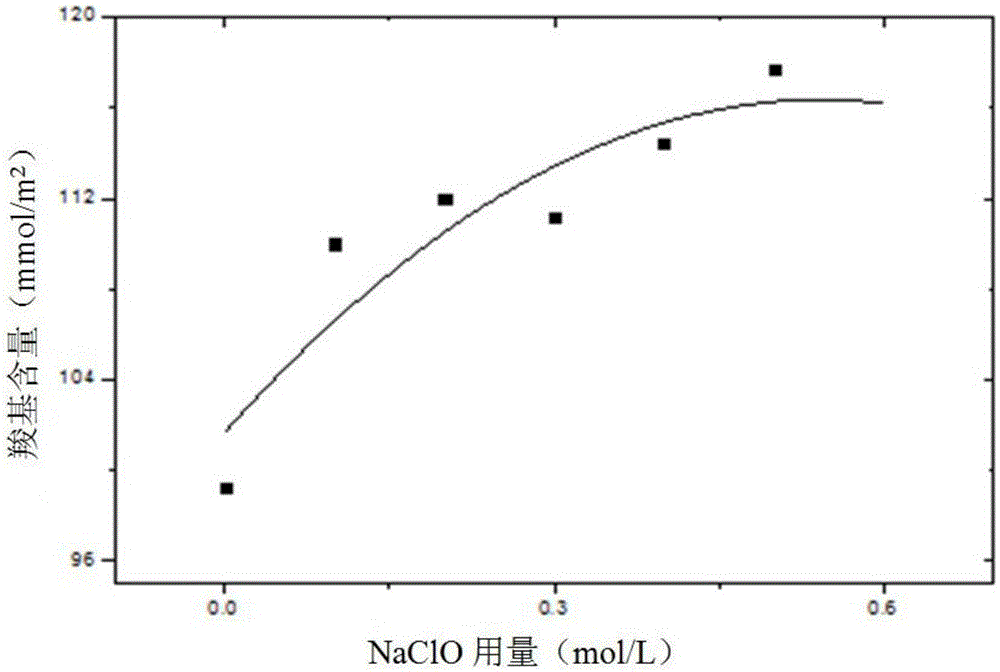

[0039] Using TEMPO, NaClO 2 and NaClO as catalyst, oxidant and co-catalyst respectively, set different reaction time, TEMPO and NaClO grades, catalyze the oxidation of the hydroxyl on the C6 position of bacterial cellulose to carboxyl, and measure the carboxyl content by conductivity titration.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com