A method for characterization of moisture accuracy at the outlet of dried silk

A technology for outlet moisture and characterization, which is applied in the fields of tobacco, food science, and tobacco preparation, and can solve problems such as characterization methods for outlet moisture accuracy of dried shredded silk, unfavorable shredded shredded process control, and excessive data fluctuations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

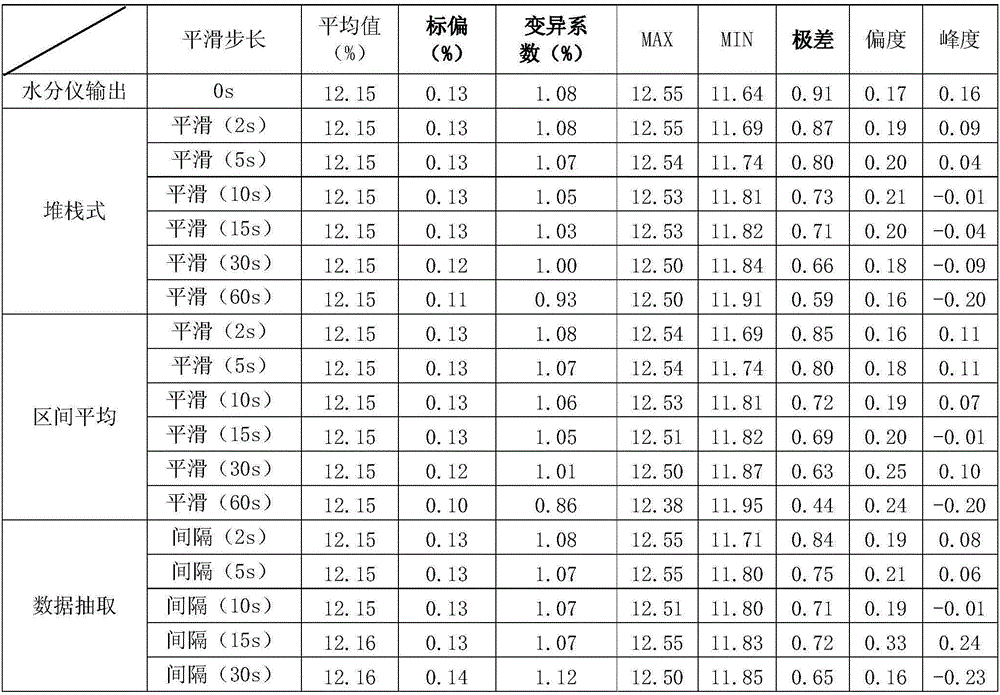

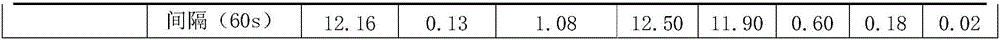

[0015] For any brand A, set the response time of the moisture meter after drying to 15s. After drying, collect the unprocessed raw data of the moisture meter itself and the output data processed by the moisture meter itself for data analysis. The results are shown in Table 1.

[0016] Table 1 Grade A moisture meter output data processing results

[0017]

[0018]

[0019] It can be seen from Table 1 that the average value of each group of data basically does not change. For the stack type and interval smoothing methods, as the smoothing step increases, the data standard deviation, variation coefficient, and range decrease continuously, and the data distribution skewness value and kurtosis values increase in variance compared to the underlying raw data. That is, after stack smoothing or interval averaging, the mean value of the data does not change much, and the degree of dispersion of the data gradually decreases. For the data extraction method, with the gradual incre...

Embodiment 2

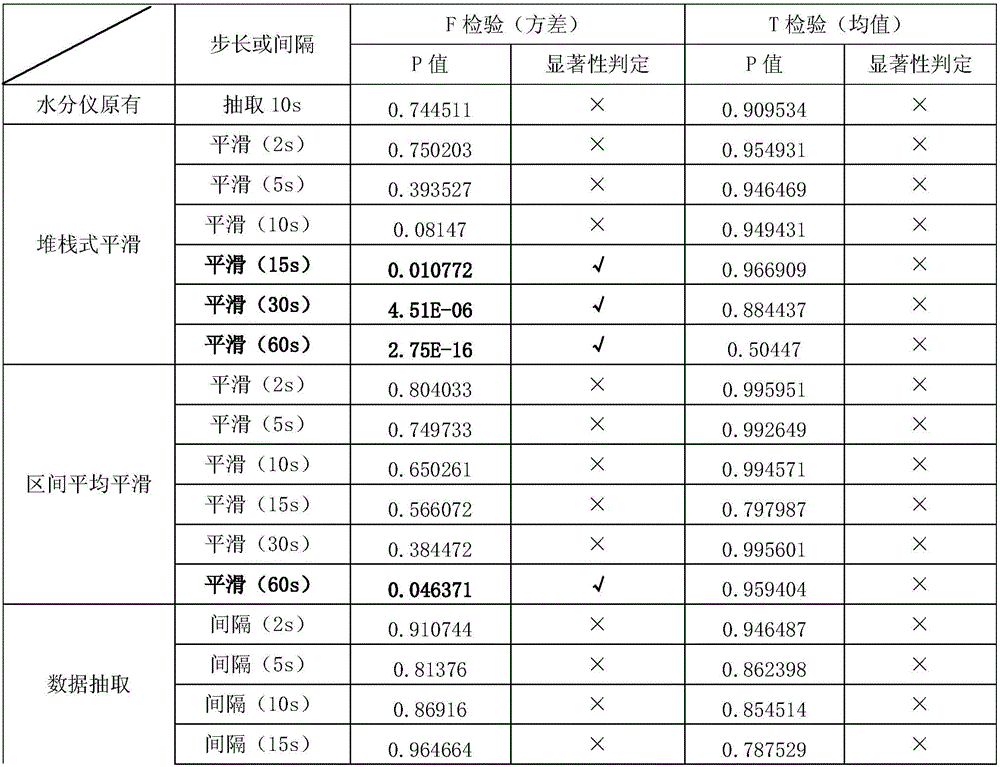

[0032] For any brand B, set the response time of the moisture meter after drying to 25s. After drying, collect the unprocessed raw data of the moisture meter itself and the processed output data of the moisture meter itself for data analysis. The results are shown in Table 5.

[0033] Table 5 Grade B moisture meter output data processing results

[0034]

[0035] Table 6 Statistical analysis results of moisture meter output data

[0036]

[0037]

[0038] Through the data processing and analysis results of the moisture meter output, on the premise of ensuring that the collected data is consistent with the average moisture content and fluctuation (discrete) of the material, the data processing rules of the moisture meter after drying are preliminarily determined, that is, the data acquisition and processing method of the upper computer adopts the data extraction method , the step size is 10s, 5s, 2s.

[0039] Table 7 Analysis of data measured by moisture meter and ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com