A kind of insect cage and breeding method for large-scale breeding of predatory natural enemy stinkbug

A technology for raising insect cages and gnats, which is applied in animal husbandry and other fields, can solve problems such as escape of adults, increased feeding costs, and egg damage, and achieve the effect of saving work and time and increasing habitat space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

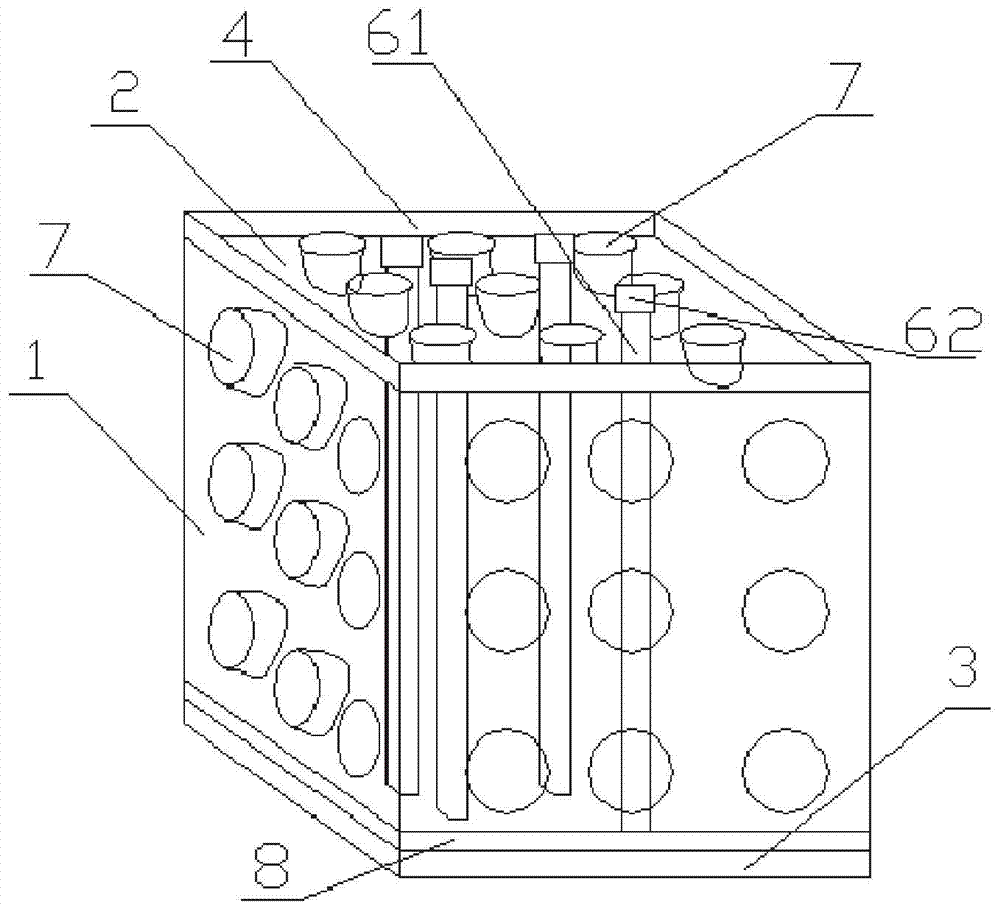

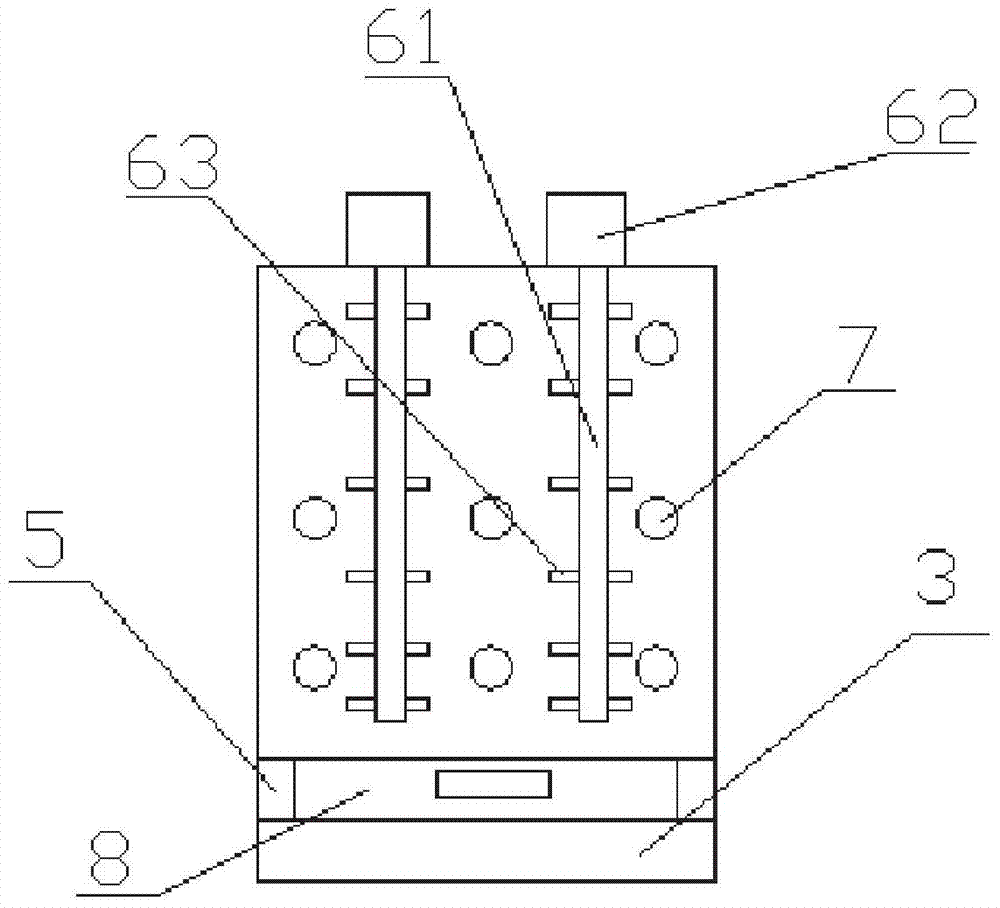

[0034] A kind of insect cage for large-scale breeding of predatory natural enemy stinkbug, comprising insect cage body, the material of insect cage body is plexiglass with a thickness of 0.5cm, including cage body 1, top cover 2 and bottom plate 3, cage body 1 Constitute an accommodating space with top cover 2 and base plate 3, and cage body 1 is the cuboid of inner side length 45cm, width 40cm, height 30cm, and its four sides are glued with width 0.5cm, thick 0.5cm and cage body at 0.5cm place from the top. 1 Load-bearing strips of the same material 4. Each side of the cage body 1 is evenly distributed with 16 mesh leak-loading holes with a diameter of 5 cm. The top cover 2 is long 45cm, wide 40cm, evenly distributed 20 diameter 5cm net leakage loading holes and 8 diameters are 2cm perches rod loading holes; Base plate 3 long 45cm, wide 40cm. Four sides are glued with wide 0.5cm, thick 0.5cm spacer strip 5 of the same material as cage body 1 at 0.5cm place from bottom plate ...

Embodiment 2

[0042] The difference between this embodiment and embodiment 1 is: the insect cage body material is a thick 0.5cm polyethylene transparent plastic, and the cage body 1 is a cuboid with an inner side length of 100cm, a width of 40cm, and a height of 30cm. Cage body 1 has 40 mesh leak-loading holes with a diameter of 4 cm evenly distributed on each side. Top cover 2 is long 100cm, wide 40cm, and evenly distributed 24 diameter 4cm net leakage loading holes and 16 diameters are 2cm perch rod loading holes; Base plate 3 is long 100cm, wide 40cm.

[0043] The difference between this embodiment and Embodiment 1 is that the reared stinkbugs are used to release and control target pests in the field, and the flat-bottomed net drain 7 and the oviposition sheet are soaked with 10% potato starch solution before starting to raise, and dried in the air. The operations before other feeding are the same as in Example 1.

[0044] The difference between the present embodiment and Example 1 also...

Embodiment 3

[0049] The difference between this embodiment and embodiment 1 is: the insect cage body material is a thick 0.5cm quartz glass material, and the cage body 1 is a cuboid with an inner side length of 15cm, a width of 10cm, and a height of 10cm. Each side of the cage body 1 is evenly distributed with 4 mesh leak-loading holes with a diameter of 4 cm. Top cover 2 is long 15cm, wide 10cm, and 4 diameter 4cm net leakage loading holes and 1 diameter are evenly distributed 2cm perch rod loading holes; Base plate 3 is long 15cm, wide 10cm.

[0050] The difference between this embodiment and Example 1 lies in that the raised stinkbugs are used for scientific research on biological characteristics, etc., and other operations before starting to raise the stinkbugs are the same as in Example 1.

[0051] The difference between the present embodiment and Example 1 is also that: when starting to raise the stink bug, 20 stink bug adults were put into the insect cage as the initial provenance. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com