A Soil Scraping and Suppression Profiling Device with Wide Compartment

A profiling device and compartment technology, applied in the field of agricultural machinery, can solve problems such as machine failure, cotton seedling burns, and increased machine load, so as to ensure stability and consistency of sowing depth, and reduce energy consumption for scraping soil , The effect of improving the passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

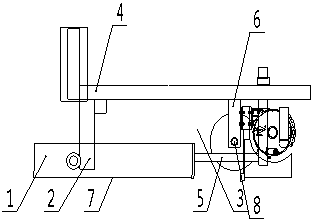

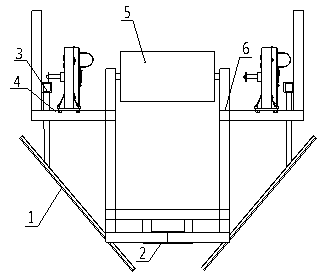

[0014] The specific structure and working principle of the present invention will be further described in the following embodiments in conjunction with the accompanying drawings.

[0015] As shown in the accompanying drawings, a wide-width compartment scraping and suppressing profiling device of the present invention includes a frame 4, two scraping boards 1 and a pressing roller 5, and is characterized in that the two scraping boards 1 pass through The front hitch 2 and the rear connecting rod 3 are fixed on the front and lower part of the frame 4 in the shape of "eight", the minimum distance between the front ends of the two moldboards 1 is between 150-300mm, and the pressure roller 5 is supported by the rotating shaft 8 and The rod 6 is installed under the frame 4 behind the moldboard 1; the lowest point of the pressing roller 5 is higher than the plane formed by the scraping blade 7 of the moldboard 1; .

[0016] The middle part of the "eight" shaped soil scraper 1 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com