vertical electric water heater

An electric water heater, vertical technology, applied in the field of vertical electric water heaters, to achieve the effects of suppressing the generation of air bubbles, increasing the heat exchange area, and reducing fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

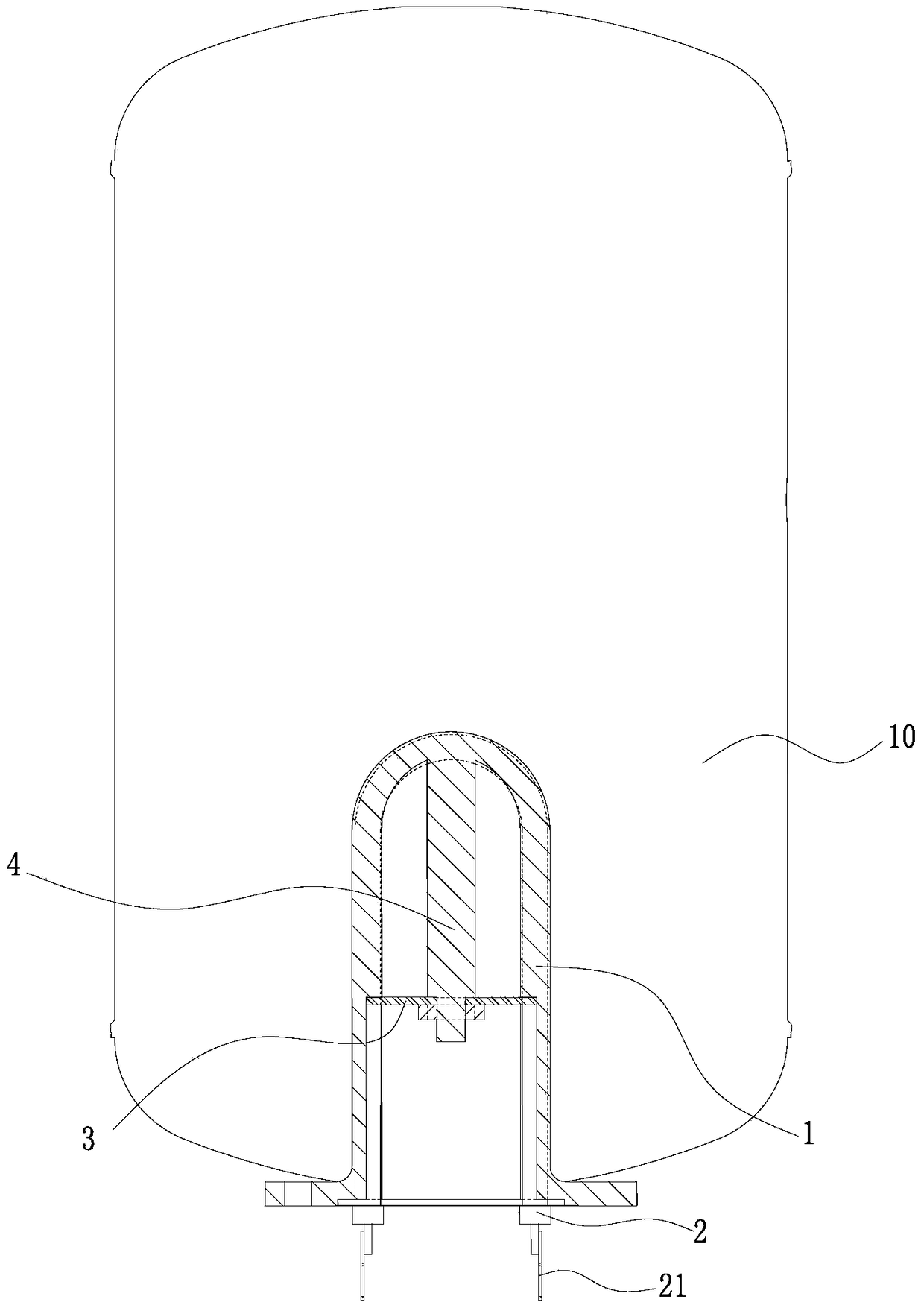

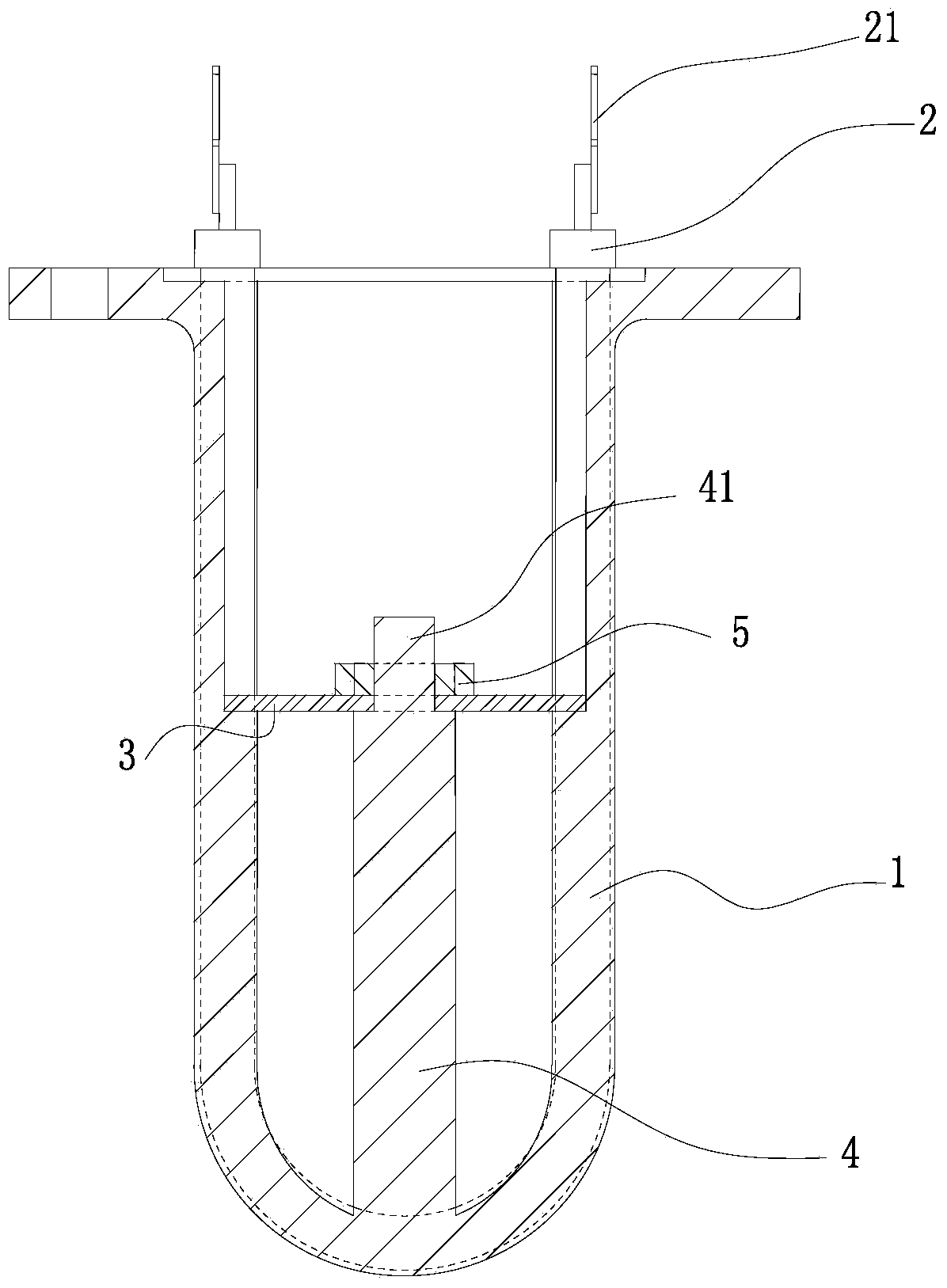

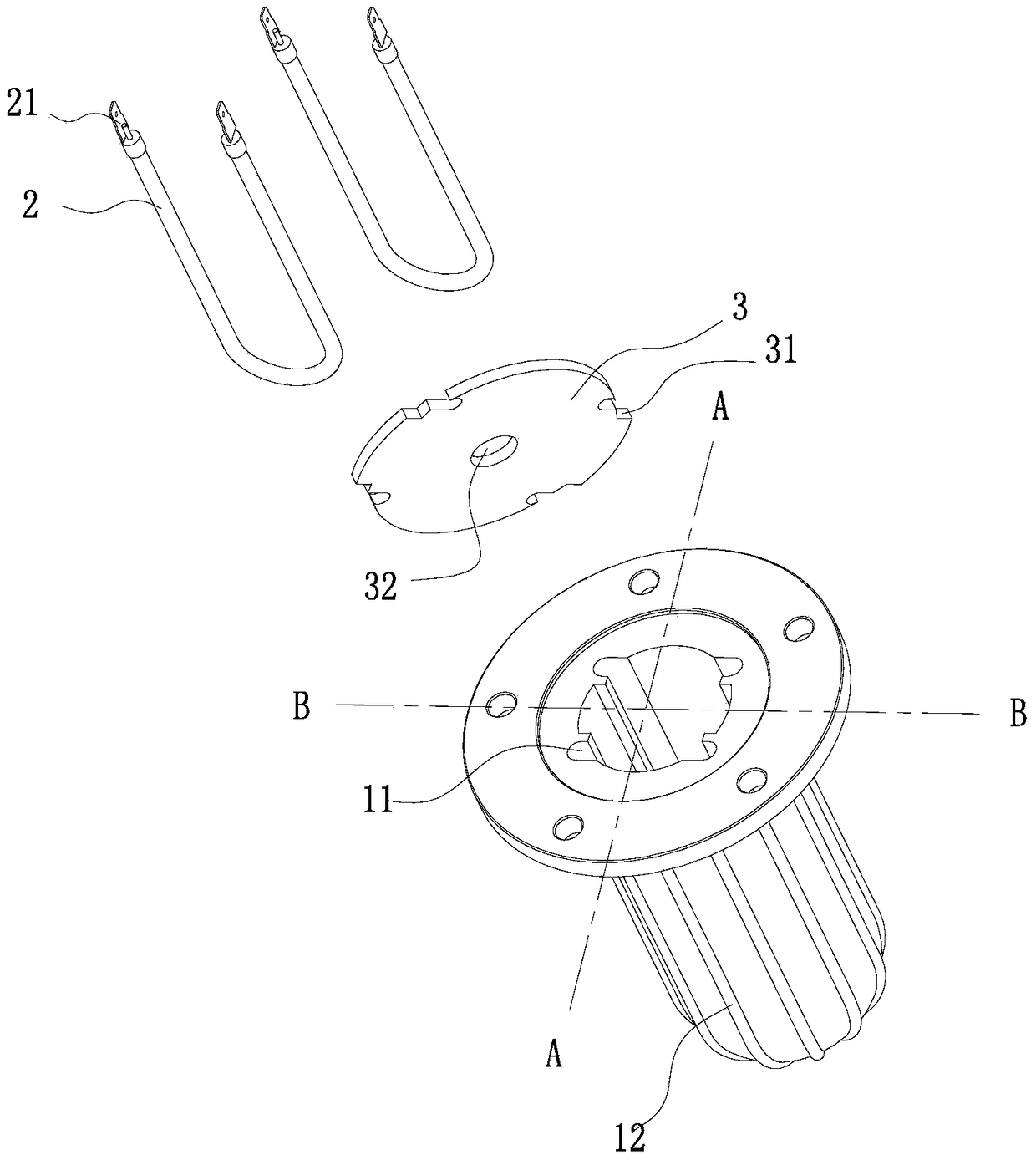

[0032] The specific implementation of the heating device for the vertical electric water heater of the present invention will now be described in conjunction with the accompanying drawings.

[0033] see figure 1 As shown in , a vertical electric water heater of the present invention is mainly composed of an inner tank 10 and a heating device in the inner tank 10. The heating device includes a heat generating cover 1 with an opening at one end, which is set in the inner cavity of the heat generating cover 1 and is connected with the heating device. At least one electric heating tube 2 (in the embodiment, there are two electric heating tubes) tightly attached to the inner wall of the heat generating cover 1, and the heat generating cover 1 is located on the longitudinal centerline of the inner container. Furthermore, the longitudinal centerline of the liner 10 coincides with the centerline of the heat generating cover 1, and the electric heating tubes 2 are evenly distributed ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com